The BRAWL² Tournament Challenge has been announced!

It starts May 12, and ends Oct 17. Let's see what you got!

https://polycount.com/discussion/237047/the-brawl²-tournament

It starts May 12, and ends Oct 17. Let's see what you got!

https://polycount.com/discussion/237047/the-brawl²-tournament

Best Of

Re: What made you feel crap today?

Vince Zampella (COD, Respawn, Battlefield) passed away in a car crash in Los Angeles.

https://www.nbclosangeles.com/news/local/video-game-developer-vince-zampella-crash-call-of-duty/3819576/

RIP

Reminded of this article,

https://gamesbeat.com/the-making-and-unmaking-of-infinity-ward/

https://www.nbclosangeles.com/news/local/video-game-developer-vince-zampella-crash-call-of-duty/3819576/

RIP

Reminded of this article,

https://gamesbeat.com/the-making-and-unmaking-of-infinity-ward/

NikhilR

NikhilR

3 ·

Re: Texturing feedback - AKM

That sort of research/thinking is key to getting a believable look.

if this is an 'in service' weapon for an actual military I don't think it would be allowed to get into this state - you'd revarnish or replace parts before it happened and I'm positive you wouldn't let anything get rusty (rusty bits stop gun shooting). If we're talking about some sort of scrappy insurgents that scavenged the equipment and hide it in the woods that's a different matter entirely though.

Agree with Sacboi on the metals - spend a bit of time watching forgotten weapons videos on AK derivatives and you'll learn all sorts of stuff about how they were made and get some insights onto what flaws there are in the design - this is all food for decision making when trying to represent the materials.

The below picture is an ak74 I googled in what I would assume is acceptable condition for military use.

I've called out some of the interesting wear and importantly the materials it's made of which have a significant effect on how wear patterns develop

These things are painted, not blued/parkerised/whatever which is important.

The receiver is primarly made of thin, cheap stamped steel which is pretty soft - it will take scratches pretty readily but tend to lose paint less easily than harder surfaces

The harder steels used for rivets/charging rod and trunion will scratch much less easily and as you can see the paint will tend to wear or flake off long before any change happens to the underlying surface

it's interesting to see how crude the surface machining is on the harder parts and that they simply painted over it

On a positive note the varnish wear effect on your lower handguard wood looks really nice - if that amount of wear was allowed to happen I'd expect the underlying wood to have gotten dirty/greasy and be a darker tone and i feel like the wear in the middle (hand holdy bit) is overdone but you've done a great job on the transition between materials.

if this is an 'in service' weapon for an actual military I don't think it would be allowed to get into this state - you'd revarnish or replace parts before it happened and I'm positive you wouldn't let anything get rusty (rusty bits stop gun shooting). If we're talking about some sort of scrappy insurgents that scavenged the equipment and hide it in the woods that's a different matter entirely though.

Agree with Sacboi on the metals - spend a bit of time watching forgotten weapons videos on AK derivatives and you'll learn all sorts of stuff about how they were made and get some insights onto what flaws there are in the design - this is all food for decision making when trying to represent the materials.

The below picture is an ak74 I googled in what I would assume is acceptable condition for military use.

I've called out some of the interesting wear and importantly the materials it's made of which have a significant effect on how wear patterns develop

These things are painted, not blued/parkerised/whatever which is important.

The receiver is primarly made of thin, cheap stamped steel which is pretty soft - it will take scratches pretty readily but tend to lose paint less easily than harder surfaces

The harder steels used for rivets/charging rod and trunion will scratch much less easily and as you can see the paint will tend to wear or flake off long before any change happens to the underlying surface

it's interesting to see how crude the surface machining is on the harder parts and that they simply painted over it

On a positive note the varnish wear effect on your lower handguard wood looks really nice - if that amount of wear was allowed to happen I'd expect the underlying wood to have gotten dirty/greasy and be a darker tone and i feel like the wear in the middle (hand holdy bit) is overdone but you've done a great job on the transition between materials.

4 ·

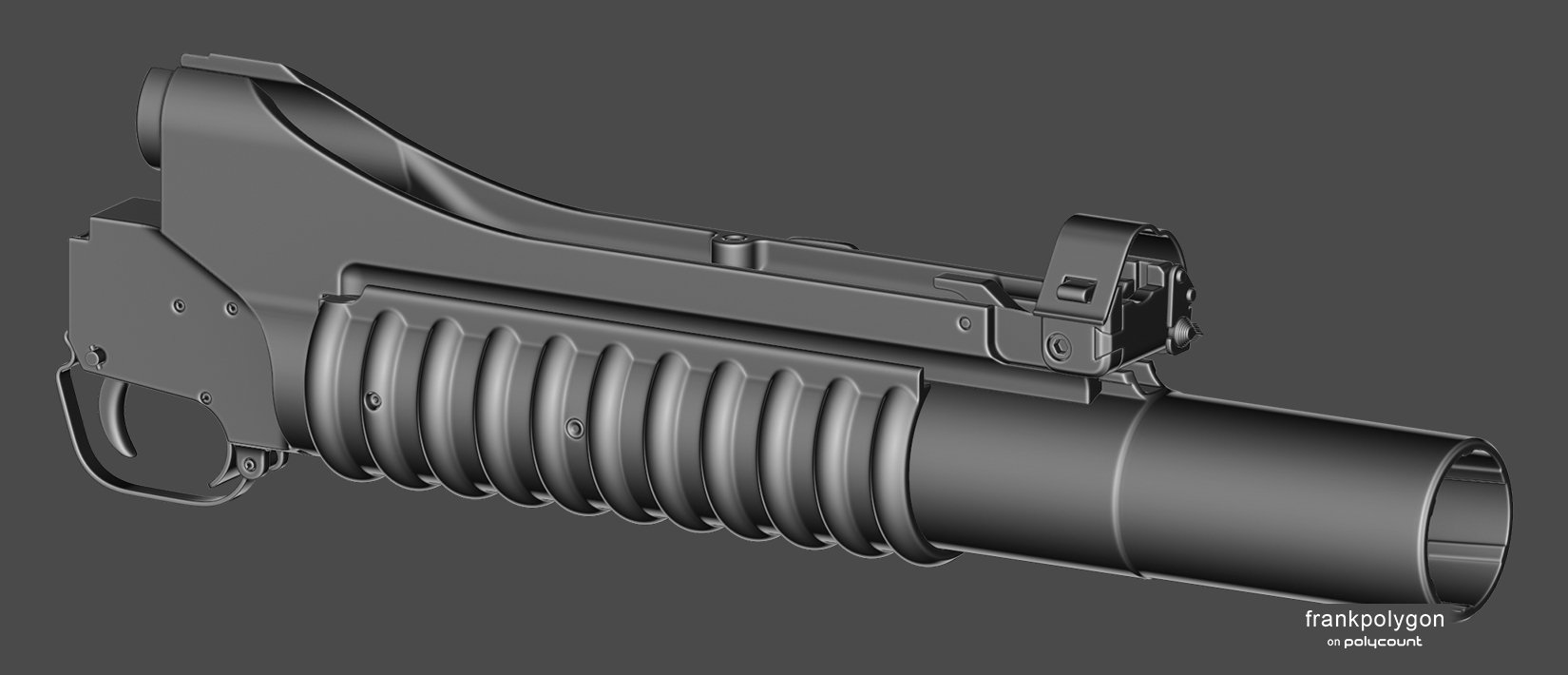

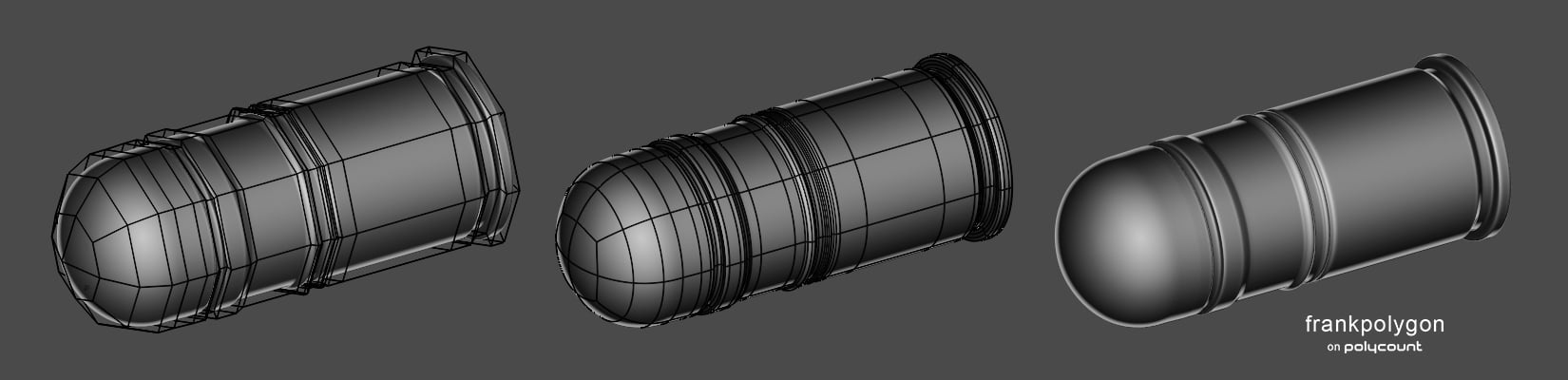

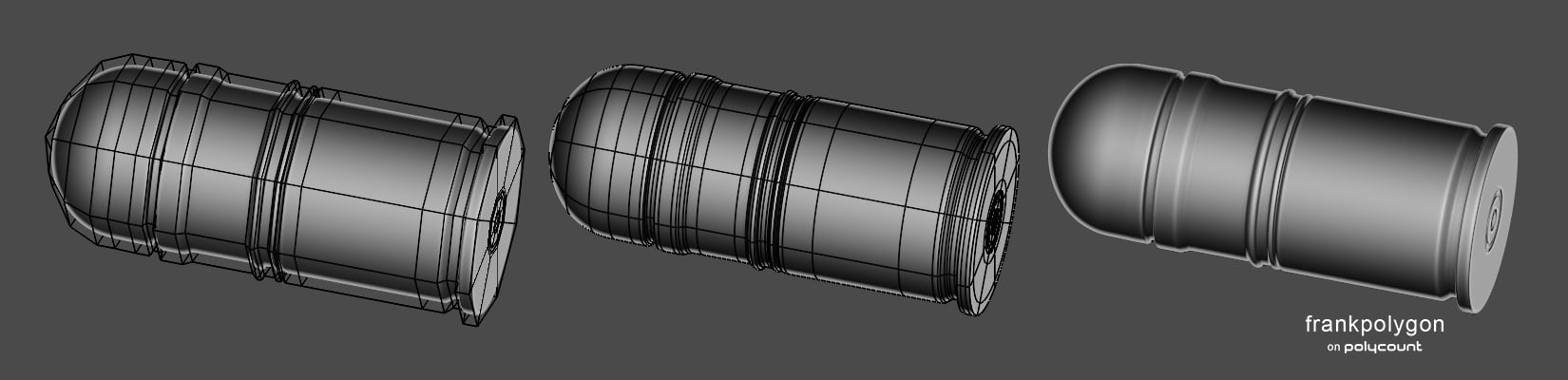

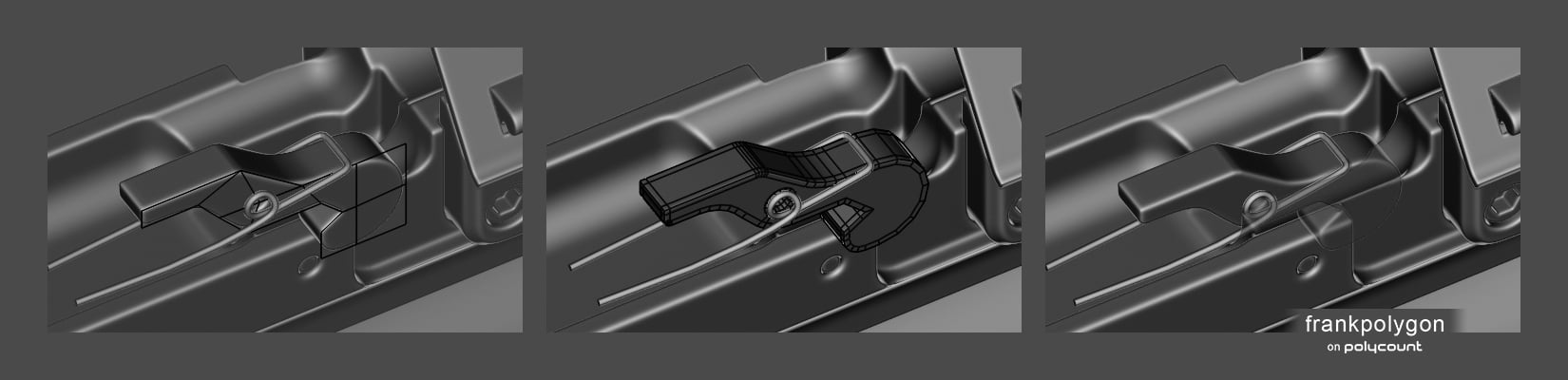

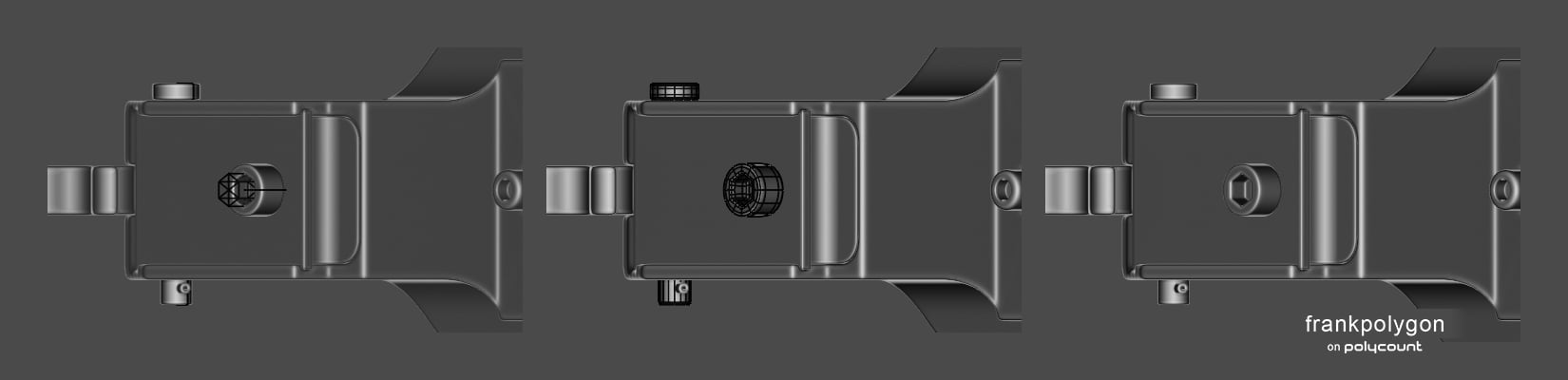

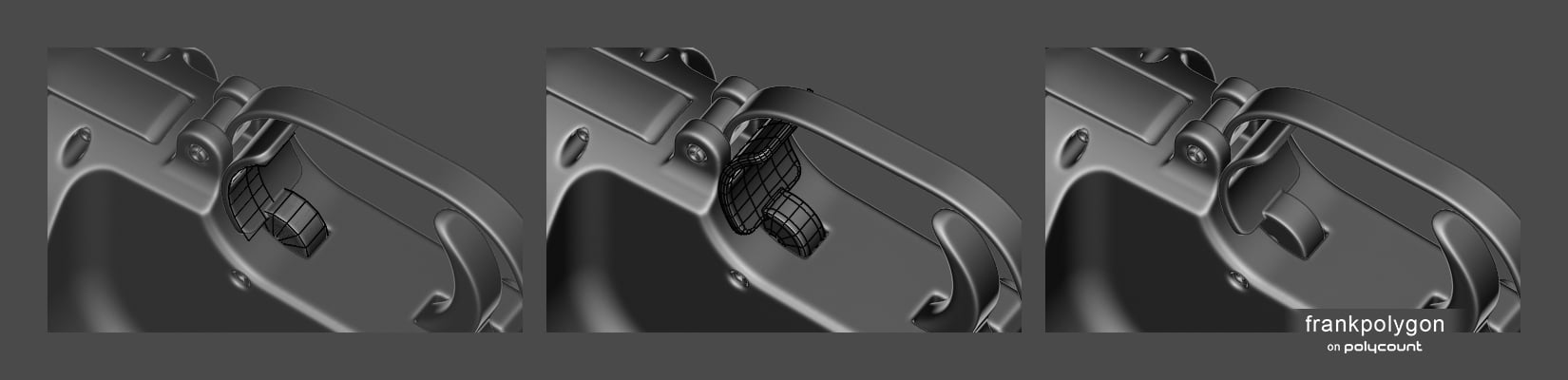

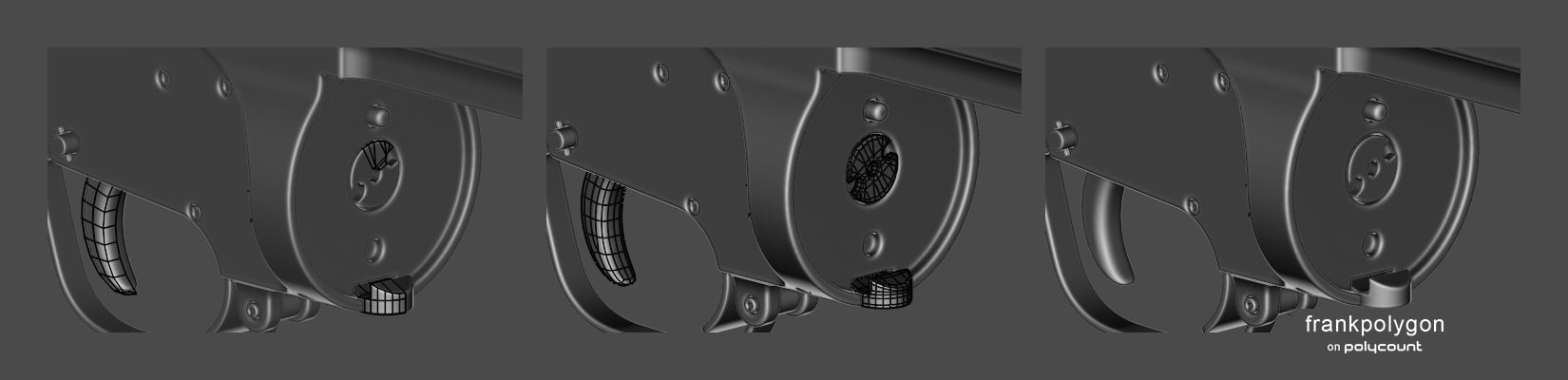

Re: Sketchbook: Frank Polygon

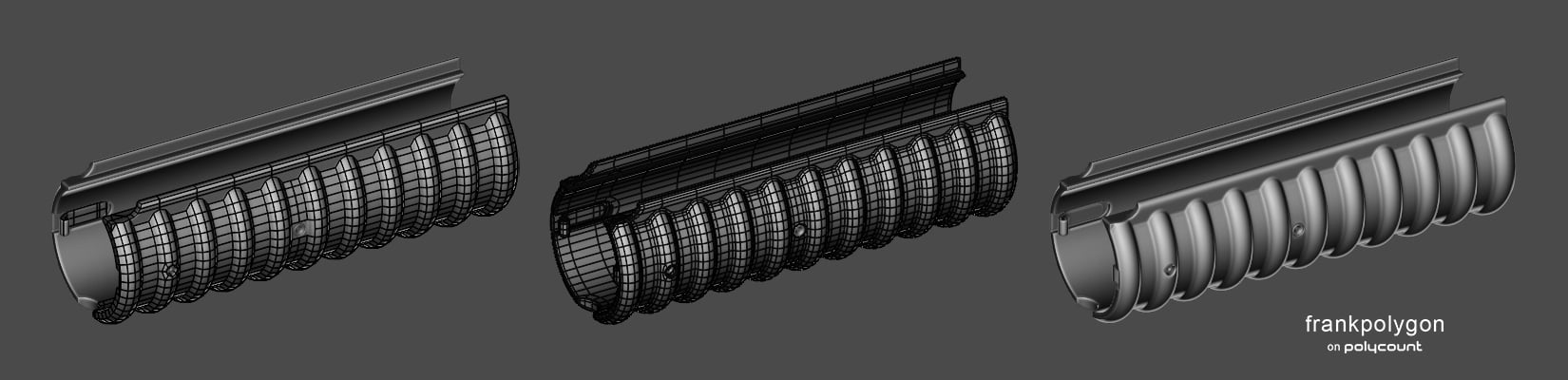

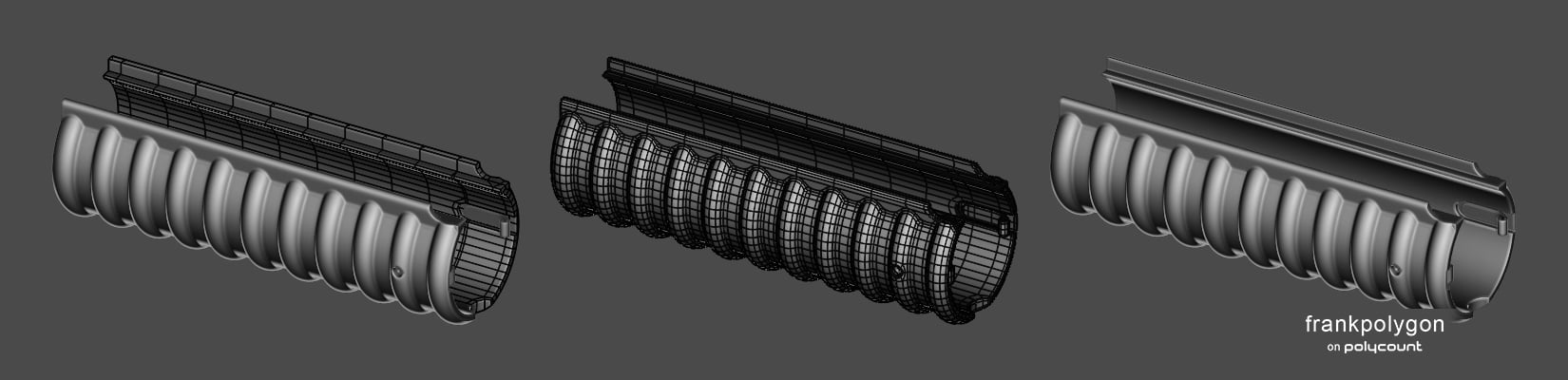

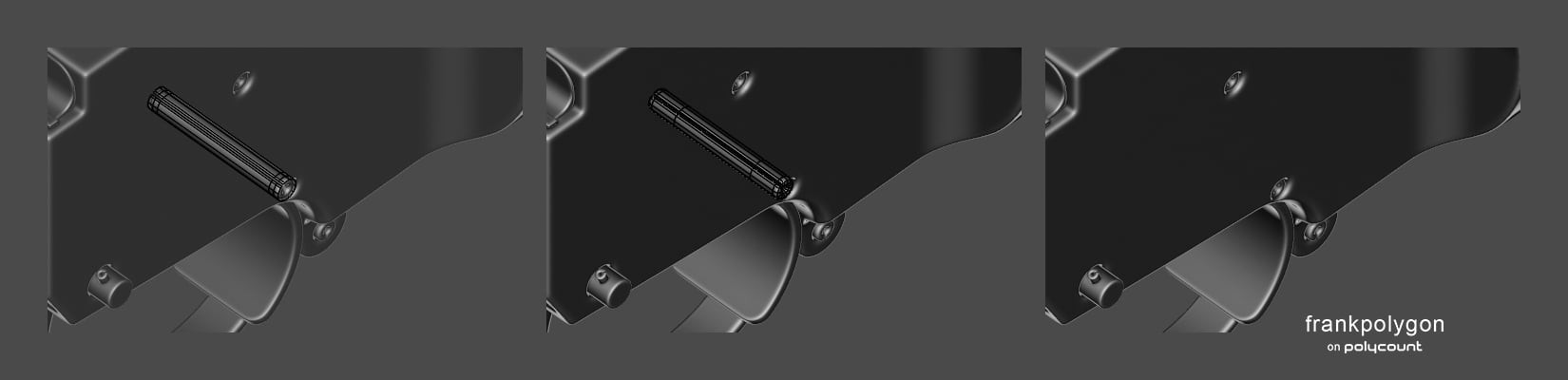

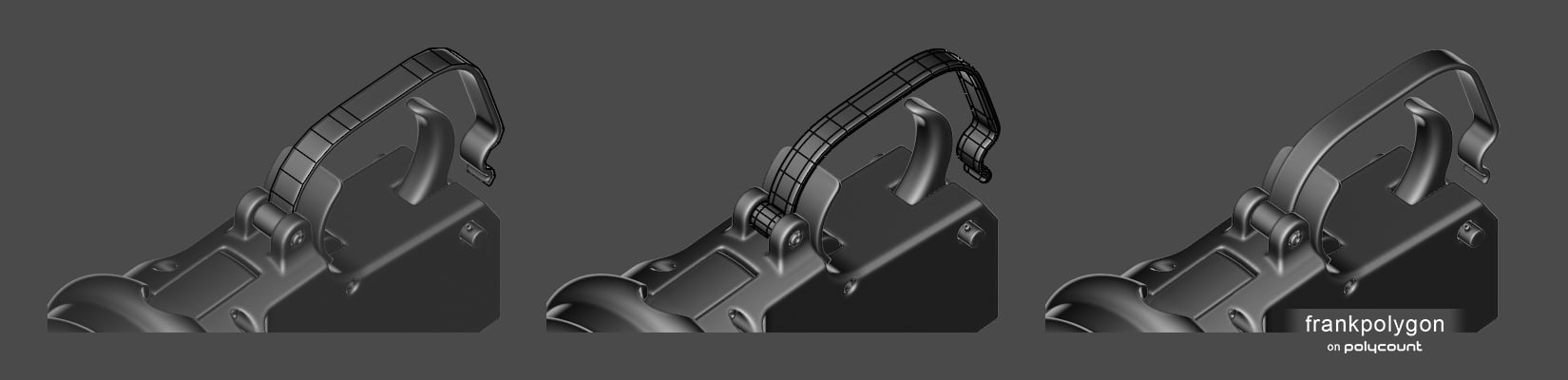

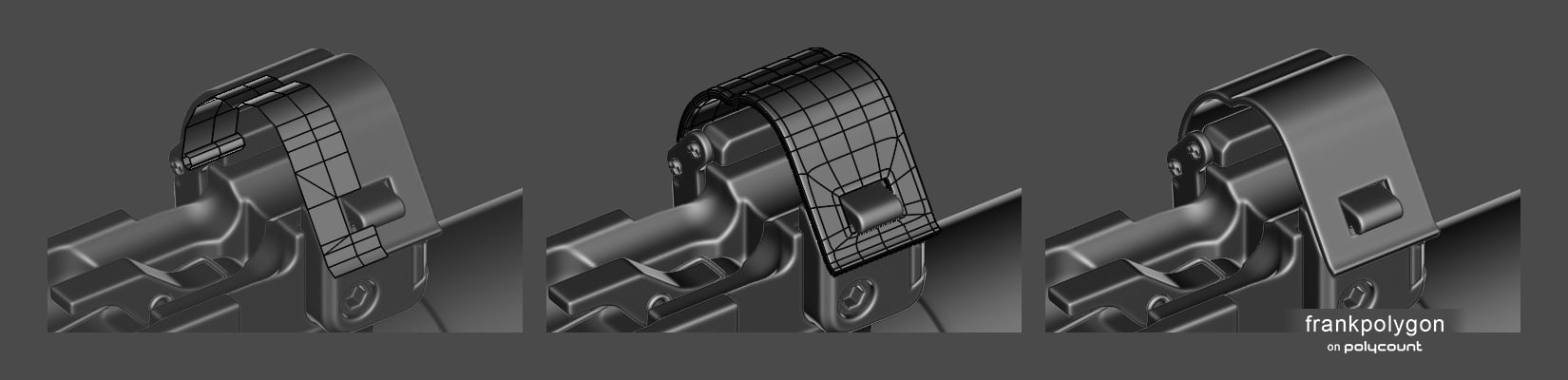

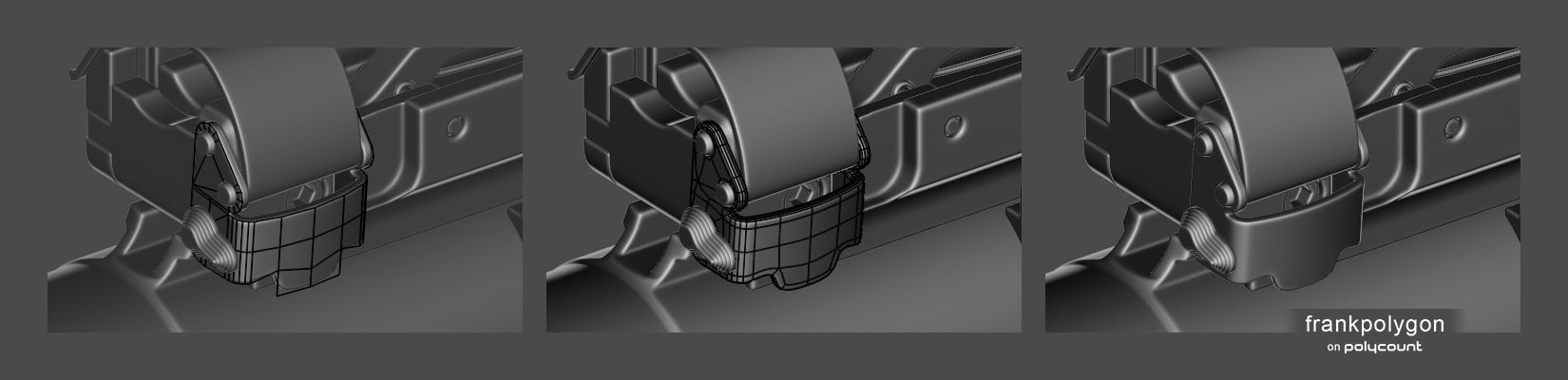

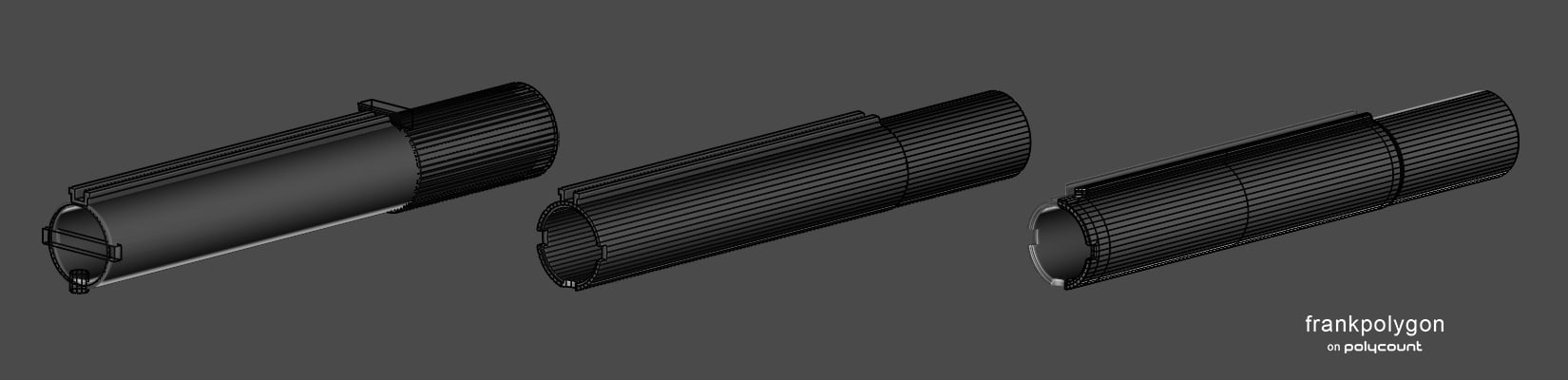

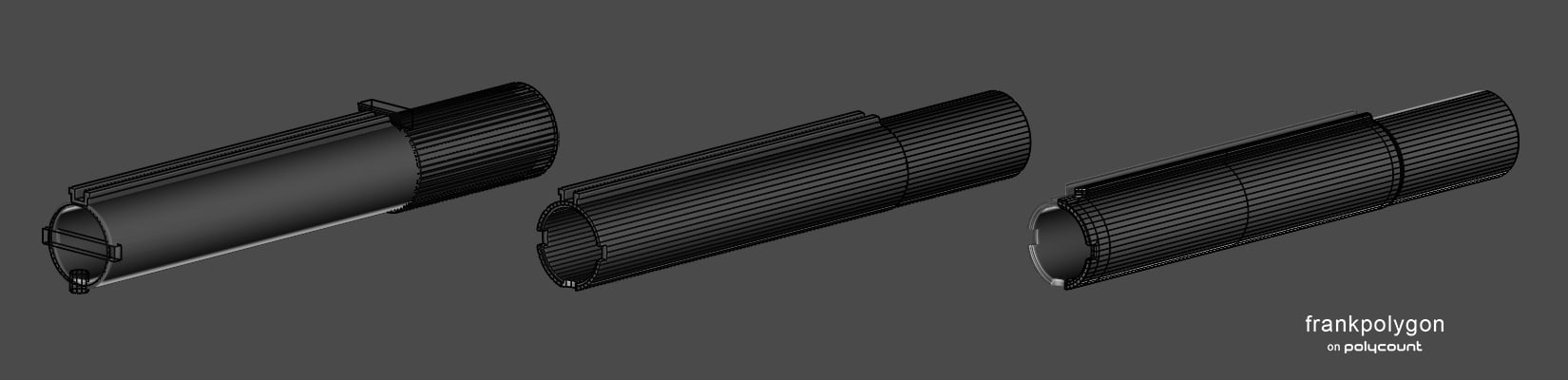

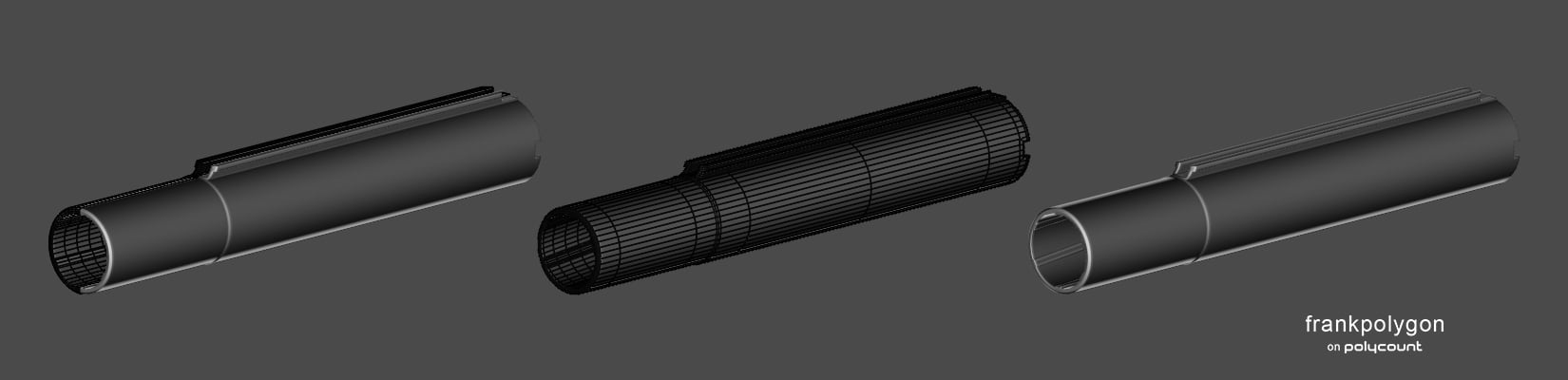

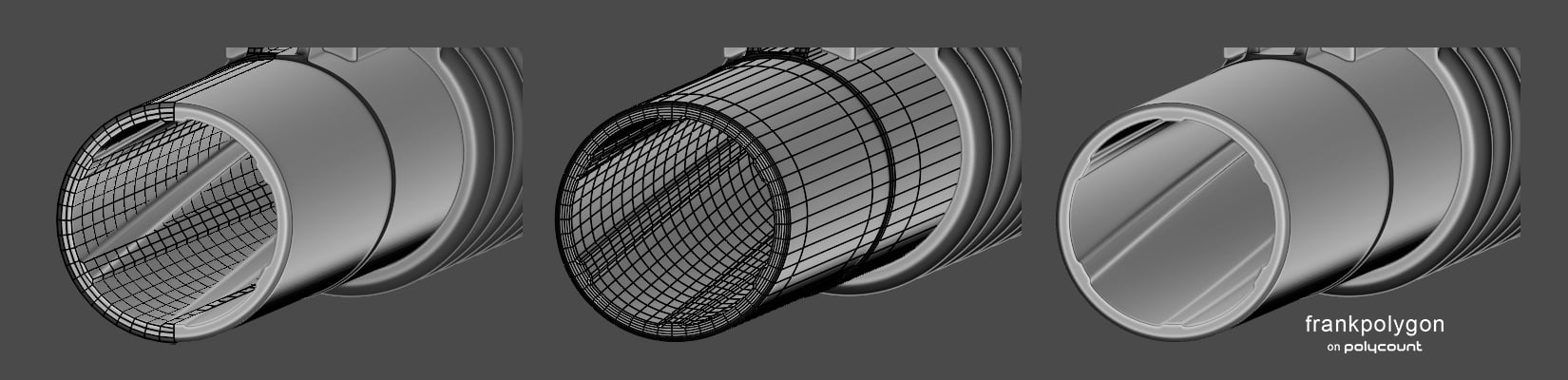

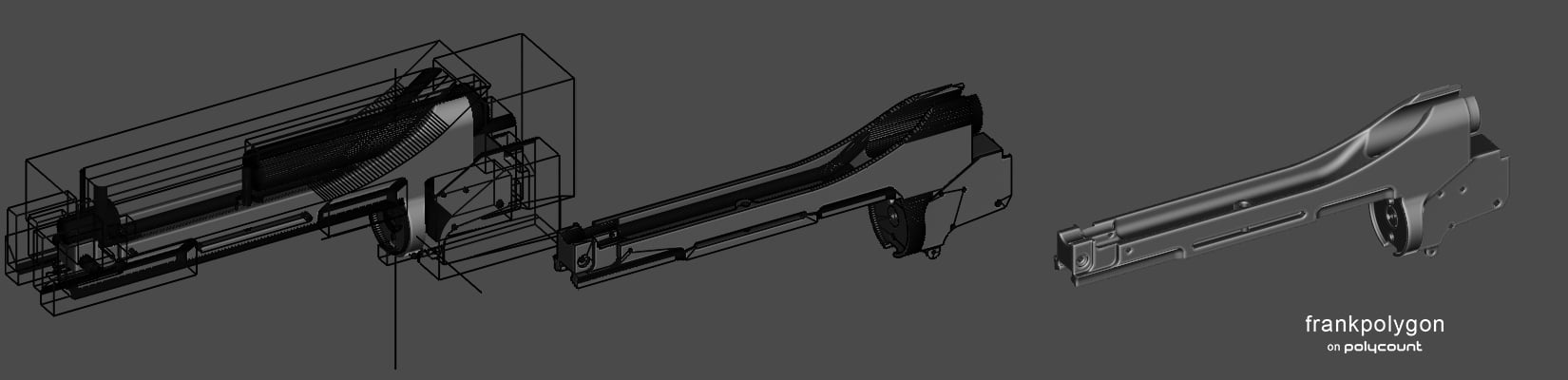

Subdivision sketch: M2O3

A quick visual overview of some easy ways to streamline [subdivision] modeling and a continuation of the previous posts about iterative block outs, booleans, modifiers, and parametric primitives.

Less explanations. More practical demonstrations.

Less explanations. More practical demonstrations.

Start with the block out. Focus on creating accurate shapes and solving any major topology flow

issues before worrying about subdividing and adding a bunch of minor support loops. Keep things simple. Use just enough geometry to support the details and shape transitions then use the subdivision to smooth the the surfaces. Avoid unnecessary complexity. Model individual components as separate meshes and use well supported flat areas to terminate extraneous loop paths.

Bevel / chamfer + Subdivision modifiers. One of the easiest ways to streamline a subdivision modeling workflow is to move away from manually cutting in every single support loop. Instead focus on resolving major loop paths first then use a bevel / chamfer modifier, controlled by face angle or edge weights, to automatically generate all of the smaller support loops used to sharpen transition areas and the edges of the shapes.

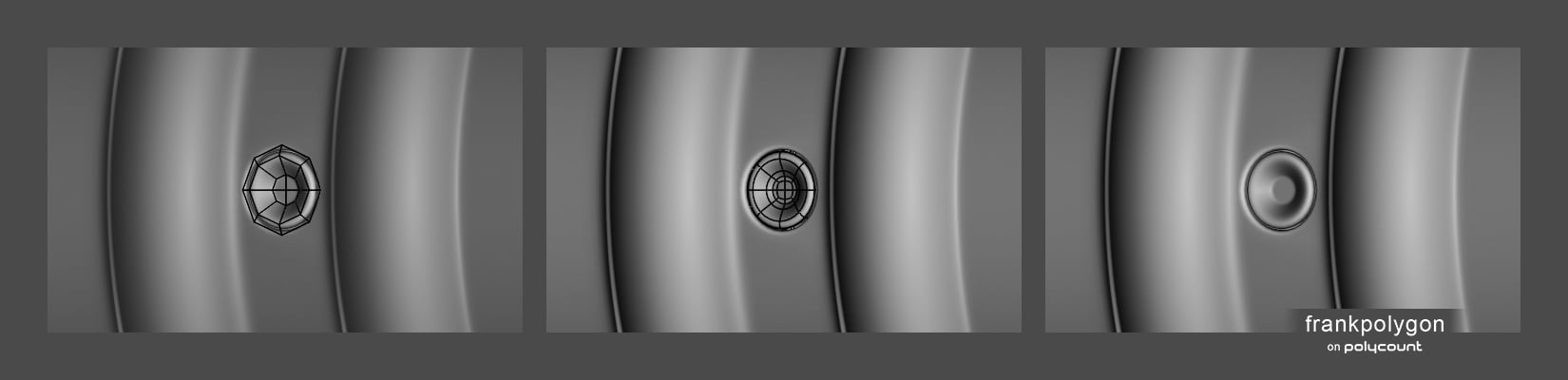

Recessed floaters are a great way to fill in small details without having to carry across a bunch of extraneous loops from the adjacent shapes. Since these floaters are below the surface it's a lot easier to hide any potential overlap issues in the natural break between the shapes.

Boolean base mesh + Mirror + Bevel / chamfer + Array + Subdivision. Use parametric primitives and boolean modifiers for a quick, non-destructive block out. Convert that to an editable mesh, mirror it, then adjust the topology routing and add the edge weights that control the bevel / chamfer modifier generating the support loops.

Asymmetric mirroring... It's possible to mirror a mesh with two unique sides. Just split off the section where the unique details are and attach it with an array modifier. Everything in the stack remains editable and the support loops are still non-destructively generated by the bevel / chamfer modifier.

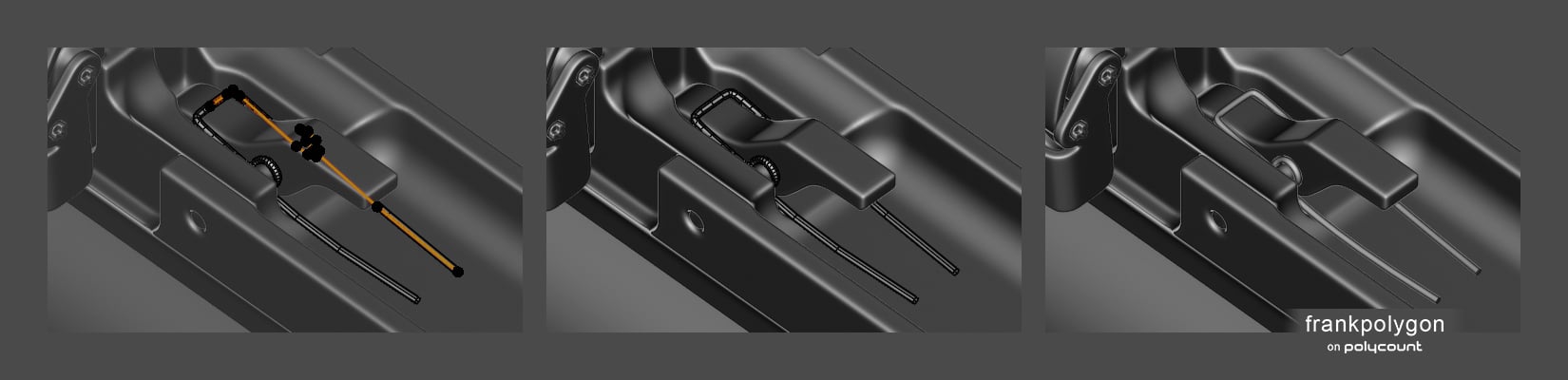

Curve to mesh + Mirror. Curves can be used to generate geometry or as a mesh deformation path. It's a lot easier to manage a few verts and edges in a curve than it is to try and manually extrude everything as regular mesh components. This works really well for modeling wires and springs.

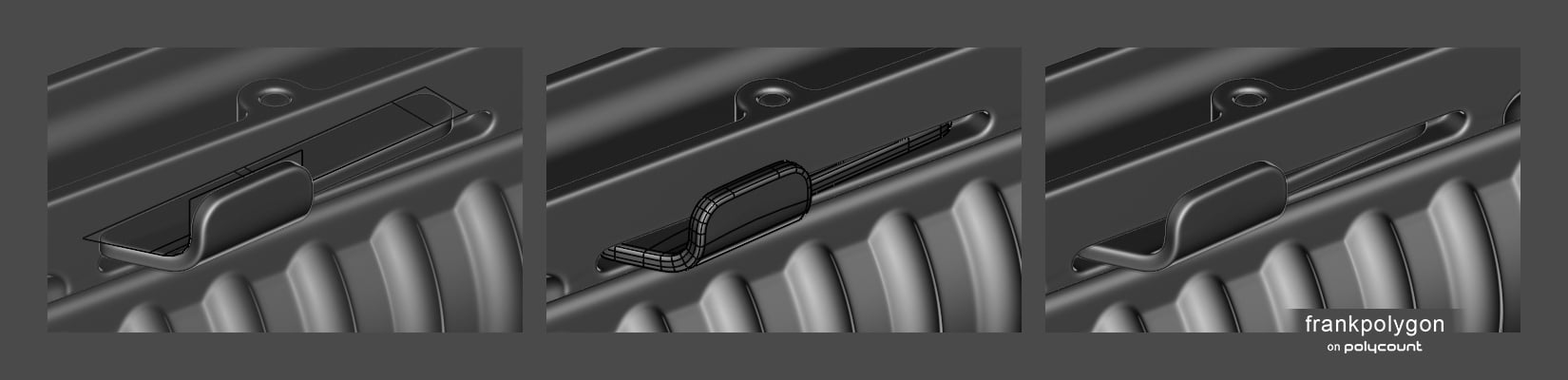

Solidify + Bevel / chamfer + Subdivision. A lot of cheap parts are made from sheet metal. No need to model everything. Just create the basic shape as a flat mesh then solidify it. Use vertex weights and a bevel / chamfer modifier to selectively round off the corners. Support loops can be automatically generated by another bevel / chamfer modifier controlled by angle or edge weights.

(The one sided base mesh in the examples below is all that needs to be modeled. Everything else is generated by modifiers that are controlled by the base mesh. It's non-destructive as long as the modifiers are active so it's pretty quick and easy to make changes to individual features.)

(The one sided base mesh in the examples below is all that needs to be modeled. Everything else is generated by modifiers that are controlled by the base mesh. It's non-destructive as long as the modifiers are active so it's pretty quick and easy to make changes to individual features.)

Roll pins.

Stamped sheet metal parts.

Compliant mechanisms.

Latch levers.

Solidify + Boolean + Bevel / chamfer + Subdivision. A similar approach can also be used to make solid parts without having to manually model all of the curves. Once again the one sided base mesh controls the final subdivision ready mesh, so any changes to it are automatically pushed through the modifier stack. Which makes it very easy to edit.

Screw + Boolean + Bevel / chamfer + Subdivision. Parametric primitives are great but sometimes it makes more sense to just draw the complex profile of a round part and spin / revolve that profile to create the base mesh. Other details like the hex socket on the head of the bolt are easy enough to create by boolean subtracting a parametric primitive. Support loops are automatically generated by a bevel / chamfer modifier set to detect adjacent faces at a specific angle threshold.

Mirror + Solidify + Boolean + Bevel / chamfer + Subdivision. Simple modifier based combination of solidifying a single sided mesh arc with a parametric primitive using a boolean union.

Boolean base mesh + Bevel / chamfer + Subdivision. Certain linear shapes work well with angle based bevel / chamfer modifiers. Just block out the shapes, add the bevel / chamfer modifier, and subdivide. No need to re-mesh something this simple.

Poly modeling + Bevel / chamfer + Subdivision. Sometimes poly modeling a base mesh is easier and quicker than setting up all the parametric primitives and booleans needed to define the shapes. The parts are simple enough that if they needed to be completely re-modeled it would only take a few minutes. Some of the round overs here are non-destructively generated by a bevel / chamfer modifier but most of it just straight poly modeling.

Parametric primitive + Boolean base mesh + Poly modeling + Bevel / chamfer + Subdivision. All of the surfaces that need to be both accurate and consistent are generated by combining parametric primitives but there's a few details that were just easier to create by poly modeling as a continuation of the boolean block out.

(Certain internal mechanical details were also excluded because they won't be visible to players and it didn't make sense to spend the time and effort on something that wouldn't be included on the in-game model.) Support loops on the high poly base mesh are generated by an edge weighted bevel / chamfer modifier.

(Certain internal mechanical details were also excluded because they won't be visible to players and it didn't make sense to spend the time and effort on something that wouldn't be included on the in-game model.) Support loops on the high poly base mesh are generated by an edge weighted bevel / chamfer modifier.

Surface floaters + Simple twist deform + Bevel / chamfer + Subdivision. There's a few different ways to create lands and grooves but surface floaters are quick and easy. The obvious downside being they need to be baked down to the low poly and depending on the textel density and poly budget it might make sense to just do this during texturing. In this case it's a large barrel so it needs to be modeled on both the high and low poly.

Geometry + Simple twist deform + Weld + Bevel / chamfer + Subdivision. A slightly more involved solution compared to simple floaters, because the lands and grooves need to line up with the segment count of the bore, but it's easy enough to do by simply modeling everything straight, running a multi loop cut operation, then using a simple twist deform to turn the geometry to the correct angle.

This mesh is mirrored and the only reason that works is there's an equal number of segments on both sides and the twist deform operation runs after the mirror operation in the modifier stack. There's an edge split between the faces on the crown and breach which allows the segments to rotate without stretching and everything is merged back down with a weld operation towards the bottom of the modifier stack.

Adjusting this part of the mesh with destructive editing is fairly straightforward since the selections are saved and if anything had to be re-modeled it could be simplified with limit dissolve then once the changes were made the loop cuts could be added back in with a single multi cut operation.

Boolean base mesh + Re-meshing + Smoothing. Pretty straightforward workflow: It's a combination of parametric primitives for key features with basic poly meshes controlling bevel / chamfer based curves and round overs. Everything in the base mesh is non-destructively editable and any changes there are automatically pushed through the modifier stack to the final re-mesh and smooth modifiers that generate the high poly model.

This could have been done with subdivision modeling. It'd be as simple as reducing the segment count on the base mesh so everything matches for easy clean up but the goal here was to use all of these different tools and workflows on a single model. Since this part is the most complex and needs to be adjusted often to match variant specific details in different references, it makes sense to use the single application re-meshing workflow because of how flexible it is and how immediate the changes are.

This could have been done with subdivision modeling. It'd be as simple as reducing the segment count on the base mesh so everything matches for easy clean up but the goal here was to use all of these different tools and workflows on a single model. Since this part is the most complex and needs to be adjusted often to match variant specific details in different references, it makes sense to use the single application re-meshing workflow because of how flexible it is and how immediate the changes are.

The re-meshing + smoothing part of the high poly model is a little bit crunchy in spots but the entire model is only 6.4 million tris so... That workflow could be pushed a little harder. It's also worth considering, when looking at reference images, the surface finish on that particular part often leaves a lot to be desired and any crunchiness in the high poly will both add to and be covered by the normal details that need to be added during texturing.

A few other things worth considering: Finding and qualifying references is it's own write-up but it's often a good idea to settle on a specific variant of whatever you're modeling. If it doesn't have to be all that accurate then at least try to stick to a specific time period or production run so the final model isn't super anachronistic or apocryphal. (Unless of course that's what the art direction calls for!)

Also, stylization is a thing but it should be both logically and visually consistent within the scope of the project. Sometimes edges can be super sharp and other times they can be really soft. Same goes for proportion, scale, and just straight up shape accuracy: sometimes it really matters and other times it just has to be close enough that the players can look at it and recognize what it is or how it works.

Figure out what the artistic and technical constraints are for the in-game model then think about how those constraints affect what the high poly needs to look like. If the poly count or textel density on the in-game model is severely limited then certain shapes may need to be simplified and the edges may need to be softer so they bake down correctly.

Along similar lines, the required detail level varies depending on the player's average view distance. Certain things may not be visible in a third person game but may be very important in a first person simulator. Knowing what can be abstracted and simplified makes modeling a lot easier because then you're not wasting time on things that don't have a direct impact on the visual quality and player's experience.

Also, stylization is a thing but it should be both logically and visually consistent within the scope of the project. Sometimes edges can be super sharp and other times they can be really soft. Same goes for proportion, scale, and just straight up shape accuracy: sometimes it really matters and other times it just has to be close enough that the players can look at it and recognize what it is or how it works.

Figure out what the artistic and technical constraints are for the in-game model then think about how those constraints affect what the high poly needs to look like. If the poly count or textel density on the in-game model is severely limited then certain shapes may need to be simplified and the edges may need to be softer so they bake down correctly.

Along similar lines, the required detail level varies depending on the player's average view distance. Certain things may not be visible in a third person game but may be very important in a first person simulator. Knowing what can be abstracted and simplified makes modeling a lot easier because then you're not wasting time on things that don't have a direct impact on the visual quality and player's experience.

Related workflow write-ups featuring parts of this model:

https://polycount.com/discussion/comment/2804901/#Comment_2804901

4 ·

Halo Infinite - Warthog M12B Variant

Many hours building this from the game series halo

Made in Maya and Render with Arnold

Main Renders

Wireframe Renders

Turntables:

Shaded

Grey

Wireframe

Made in Maya and Render with Arnold

Main Renders

Wireframe Renders

Turntables:

Shaded

Grey

Wireframe

3 ·

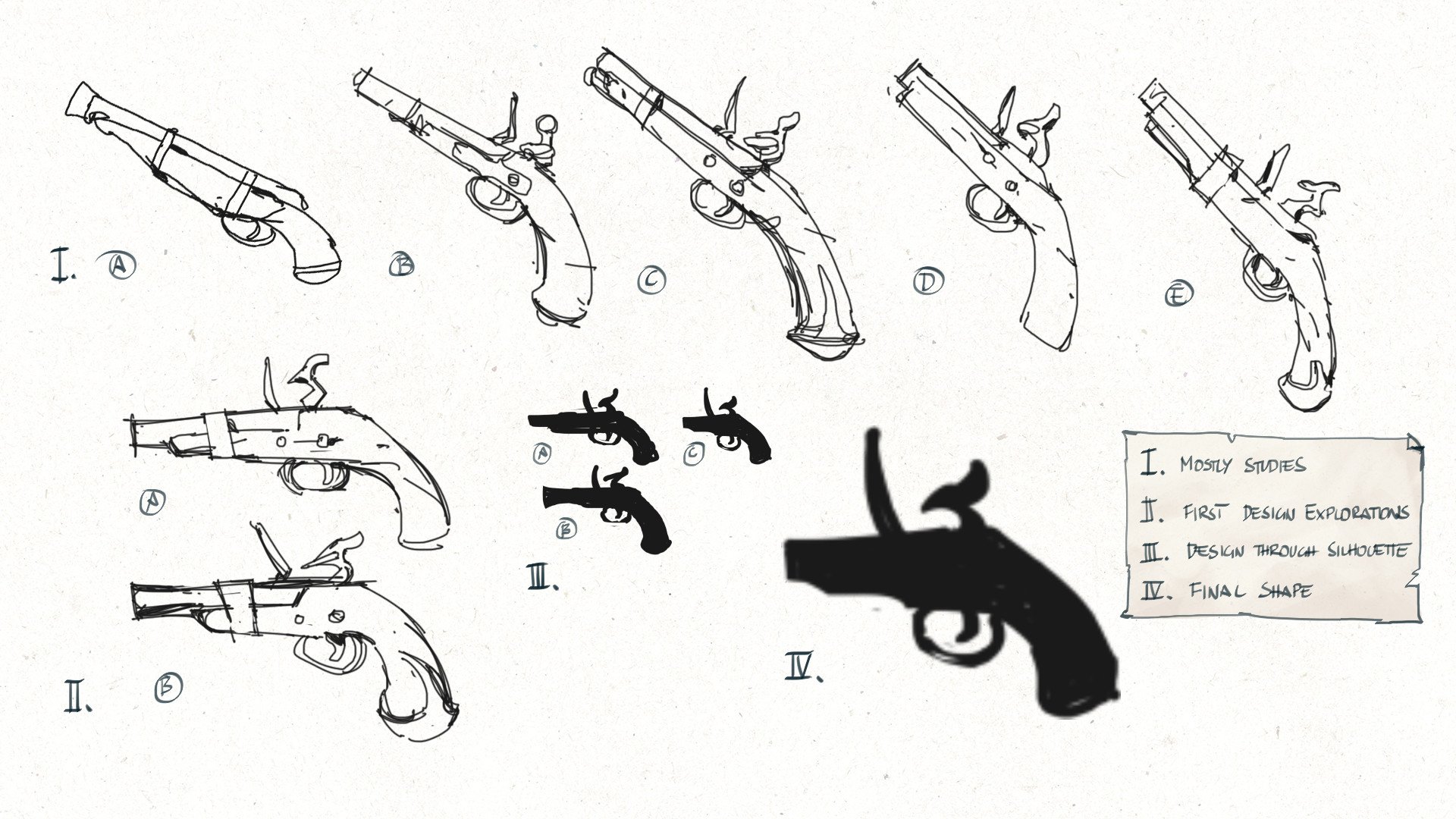

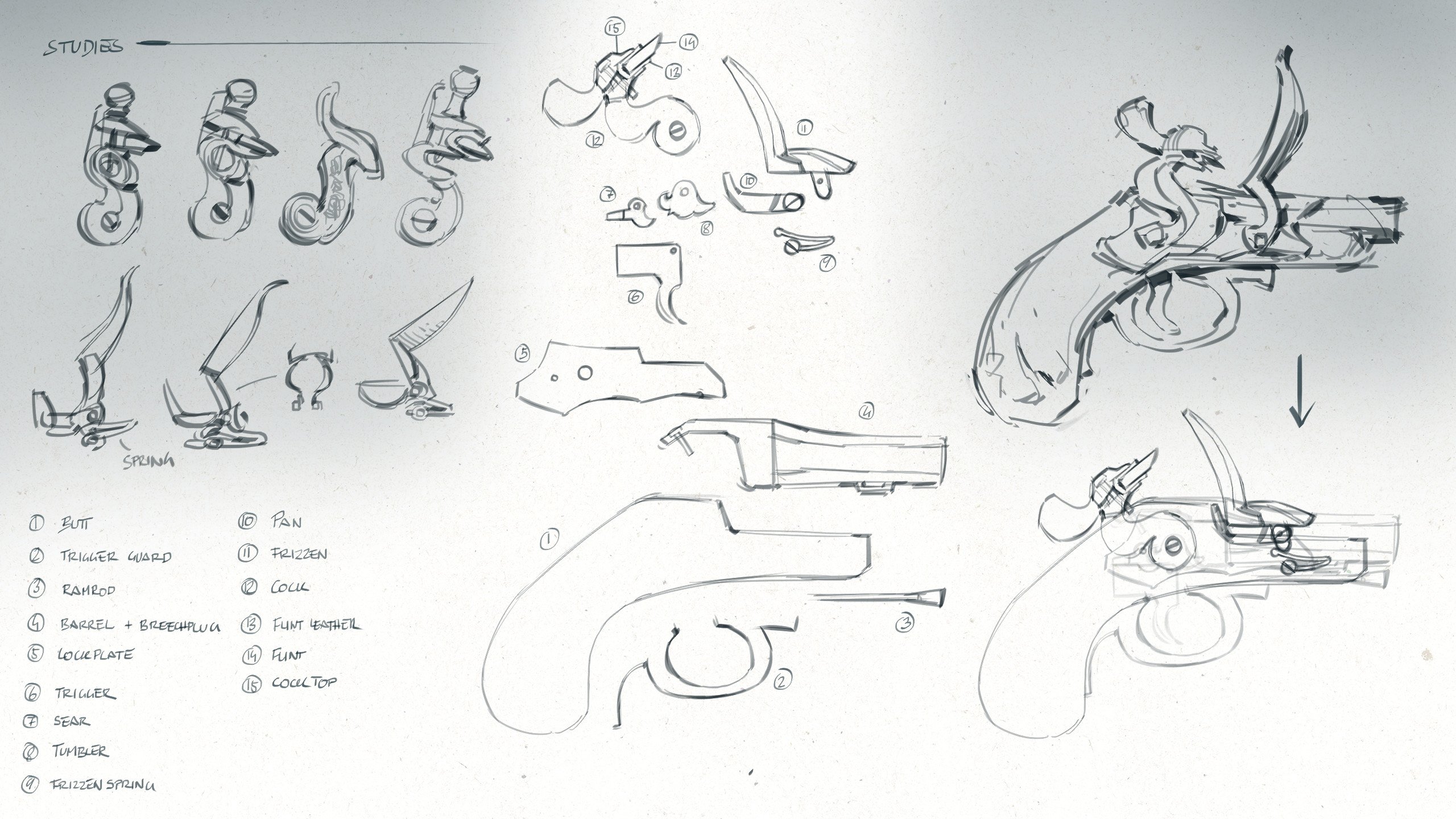

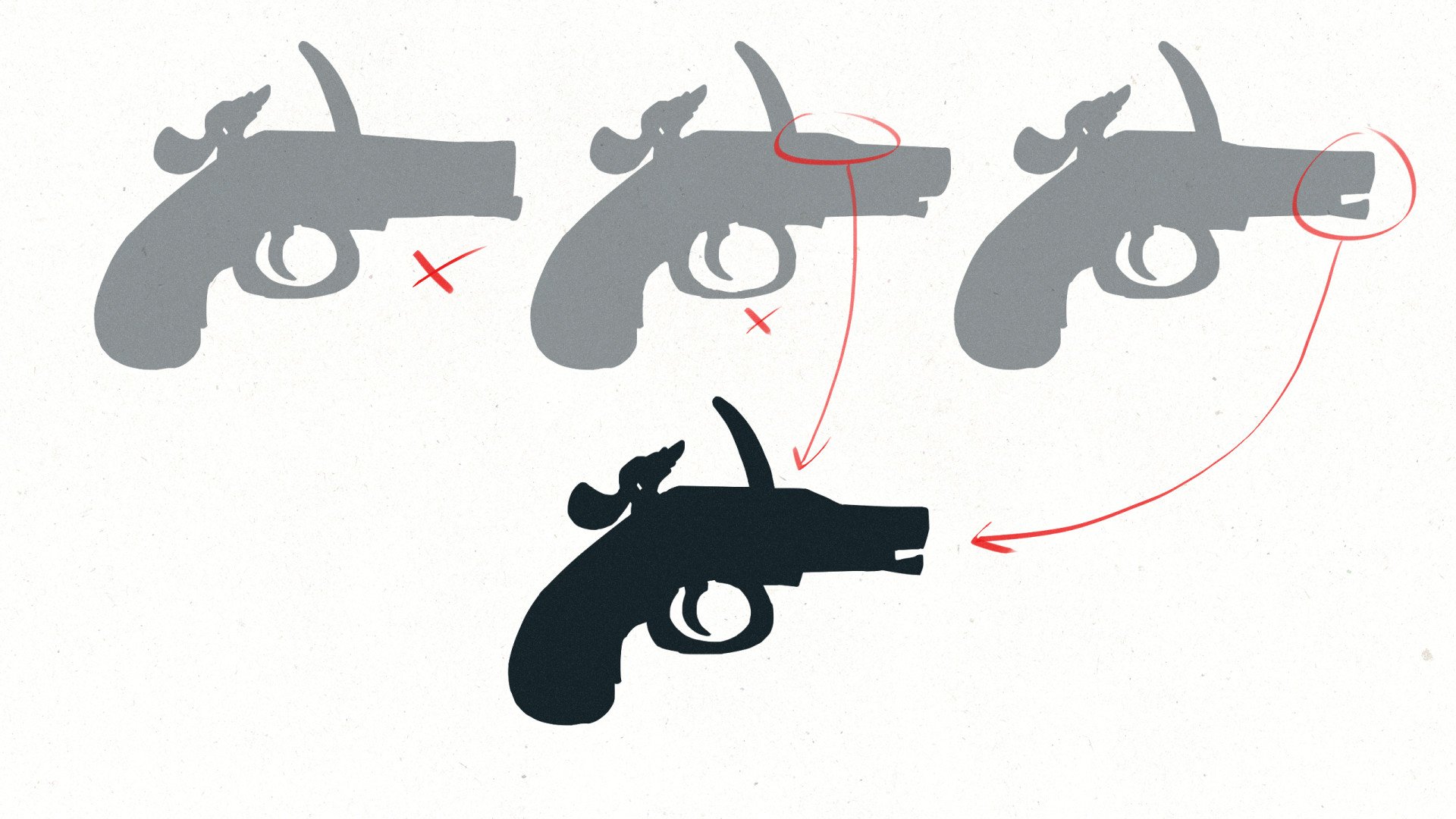

Re: Stylized Stubby Flintlock Pistol (WIP)

Design Process

Did some digging and found my design process sketches I made for the initial design.Just added some explanation to the different stages.

Initial design sketches.

And here's how I built upon the initial design, adding functional details and refining the overall shape.

Re-sketch of the initial design (top right) and, after some studies (top left), building of the individual parts; assembled (bottom right) and exploded (middle).

Further exploration and refining of the silhouette.

domfiglhuber

domfiglhuber

4 ·

Re: Sketchbook: sacboi

Represents about 12.5 hrs + breaks & revisions, really smashed finish up next sesh.

_______________________________________________________________________________________________________________________________________________

March 4 2021

sacboi

sacboi

3 ·

Re: Sketchbook: sacboi

First Portrait Complete.

Which was fairly straightforward, less fiddly than initially thought and not bad if I may shamelessly say so myself

Next one up, IG-11 mech...

sacboi

sacboi

3 ·

Re: Sketchbook: sacboi

Well, apparently there's more too drawing with curves than I'd initially thought...and then some O_o

So after peeping various resources, had eventually settled upon a proprietary budget option as opposed to a wholly FOSS paradigm simply to make the learning process less mind bending grindie-'ish for yours truly. However that said will definitely revisit an Inkscape vector workflow sometime in the foreseeable future once I've calibrated an intuitive, efficient, personal 2D 'painting with shapes' methodology which hopefully taking another crack at carrying *my ride* project above toward completion! that may or may not accrue : )

Anyways, resulting output thus far over (on 'n off) 2 month tinkering 'under-the-hood' session/s

edit:

at the moment working on generating front & rear 3/4 views

sacboi

sacboi

3 ·

[FINISHED] Game-Ready Bamboo Katana

A sword kit of a poor samurai

hope you guys like it i made it as a game-ready modular assets

i made it as a game-ready modular assets

Modelled in Blender, textured in Subtance Painter and rendered in Unreal Engine 5

Follow me on Artstation: https://manhha_khan.artstation.com/ !

hope you guys like it

Modelled in Blender, textured in Subtance Painter and rendered in Unreal Engine 5

Follow me on Artstation: https://manhha_khan.artstation.com/ !

manhha_khan

manhha_khan

4 ·

Re: AI Art, Good or Bad? A (hopefully) nuanced take on the subject.

"People want genuine things, like actual paintings", some say.

Two years after this thread was originally starated here is where we are now : "Instagram artists" scamming museums with their tracing-to-canvas-and-color-matching-within-the-lines of Midjourney slop.

This being unnoticed by a whole team of museum employees goes to show that people outside of the tech world are so incredibly uneducated on these topics. I suppose the silver lining is that at some point it's going to become so very obvious, since everyone can learn how to trace and color from reference in about a weekend.

Two years after this thread was originally starated here is where we are now : "Instagram artists" scamming museums with their tracing-to-canvas-and-color-matching-within-the-lines of Midjourney slop.

This being unnoticed by a whole team of museum employees goes to show that people outside of the tech world are so incredibly uneducated on these topics. I suppose the silver lining is that at some point it's going to become so very obvious, since everyone can learn how to trace and color from reference in about a weekend.

pior

pior

3 ·