Best Of

Re: Just another speed practice

What's your goal right now with these?

Like the anatomy topic has been repeated quite a few times and you acknowledged that in your previous post so I was wondering what your objective is with these speedsculpts?

As far as I can see, you hit a wall really fast. If you compare the first post with the last one they are quite similar skill wise. You would greatly benefit from taking it a lot slower and invested a few hours or more into one sculpt whilst using anatomy references.

But regardless of what I said. Keep having fun and keep sculpting

Cheers

But regardless of what I said. Keep having fun and keep sculpting

Cheers

3 ·

Re: Sketchbook: Frank Polygon

Thanks @Eric Chadwick , @sacboi ! Call me anything but late for dinner. Also, that Dagwood looks like a giant corn dog. Artery clogging indeed...

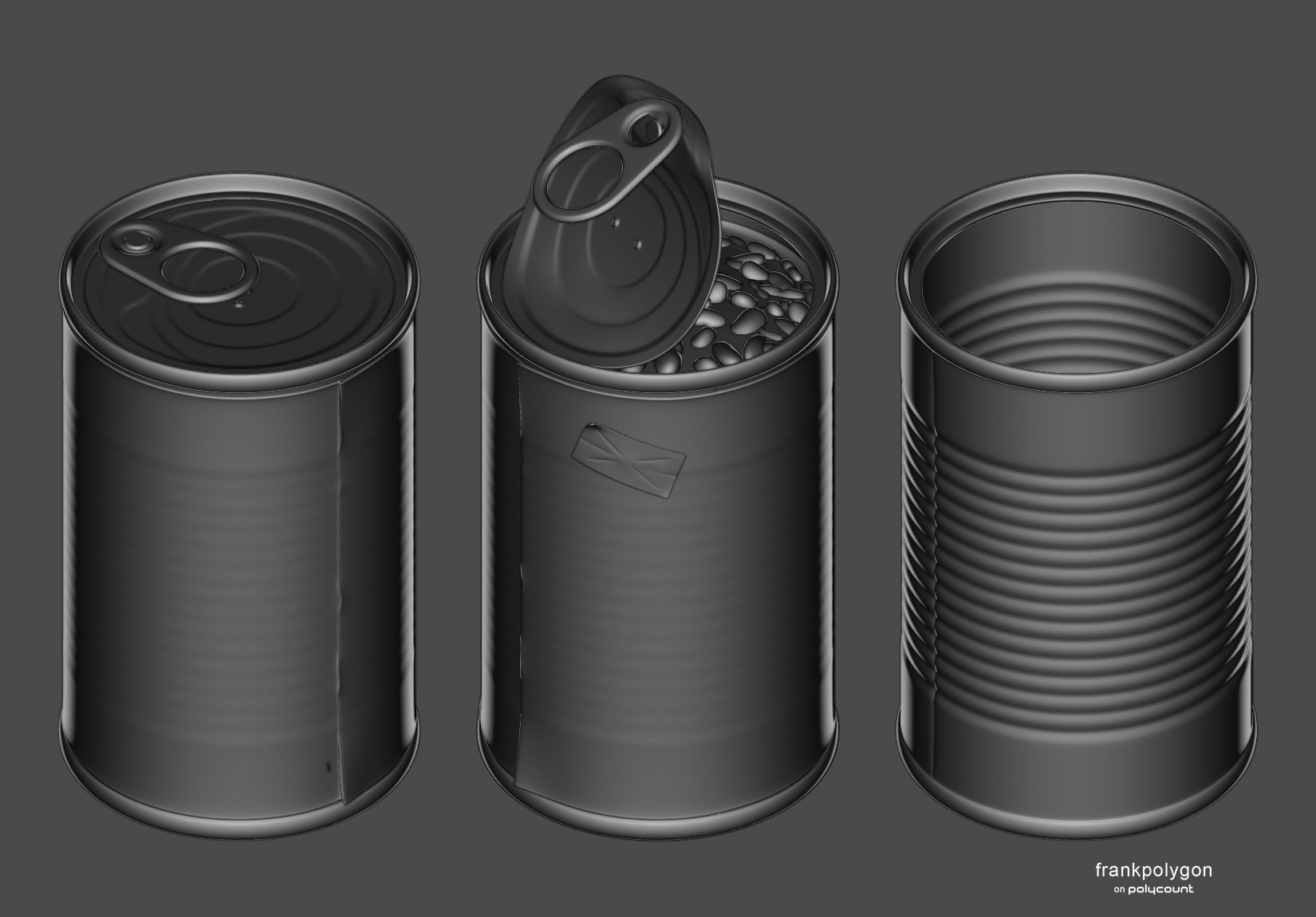

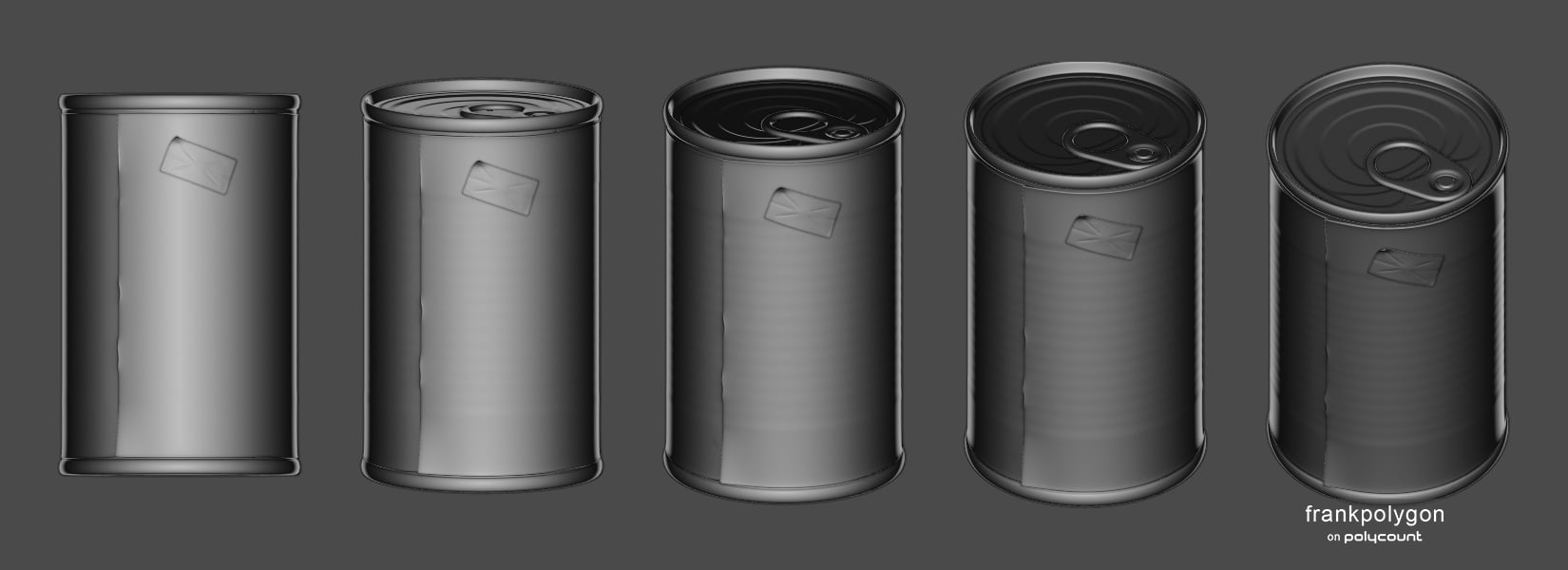

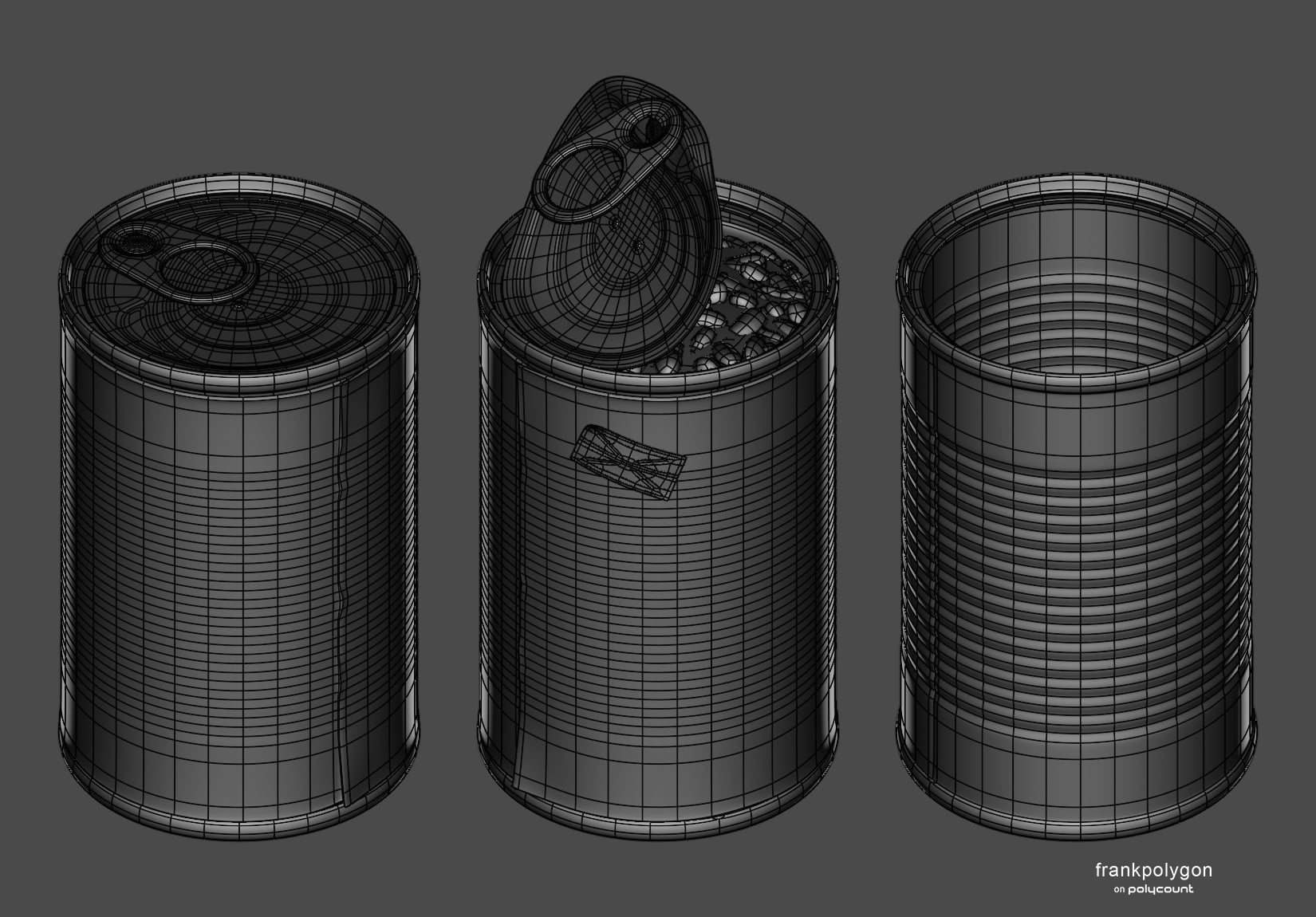

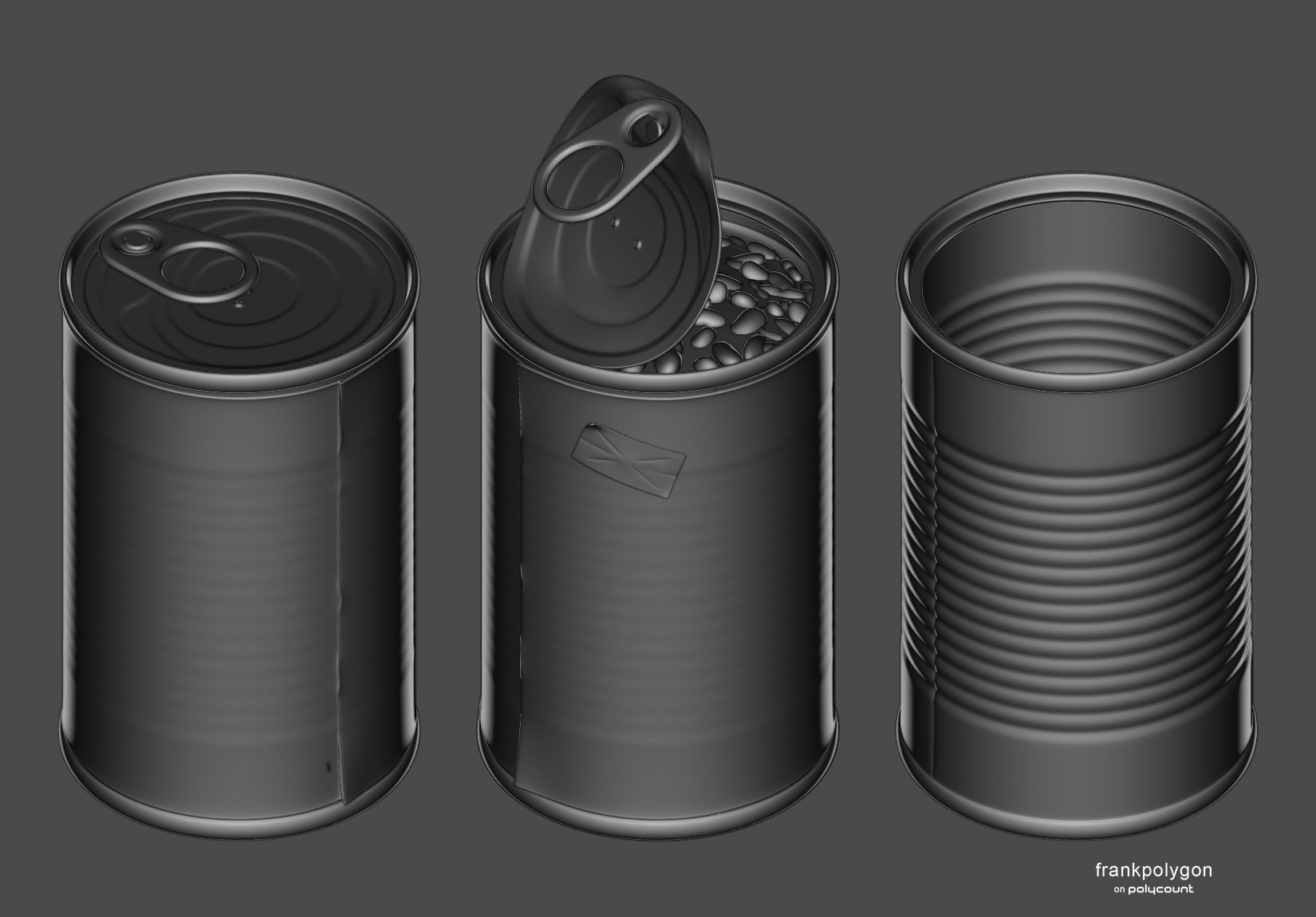

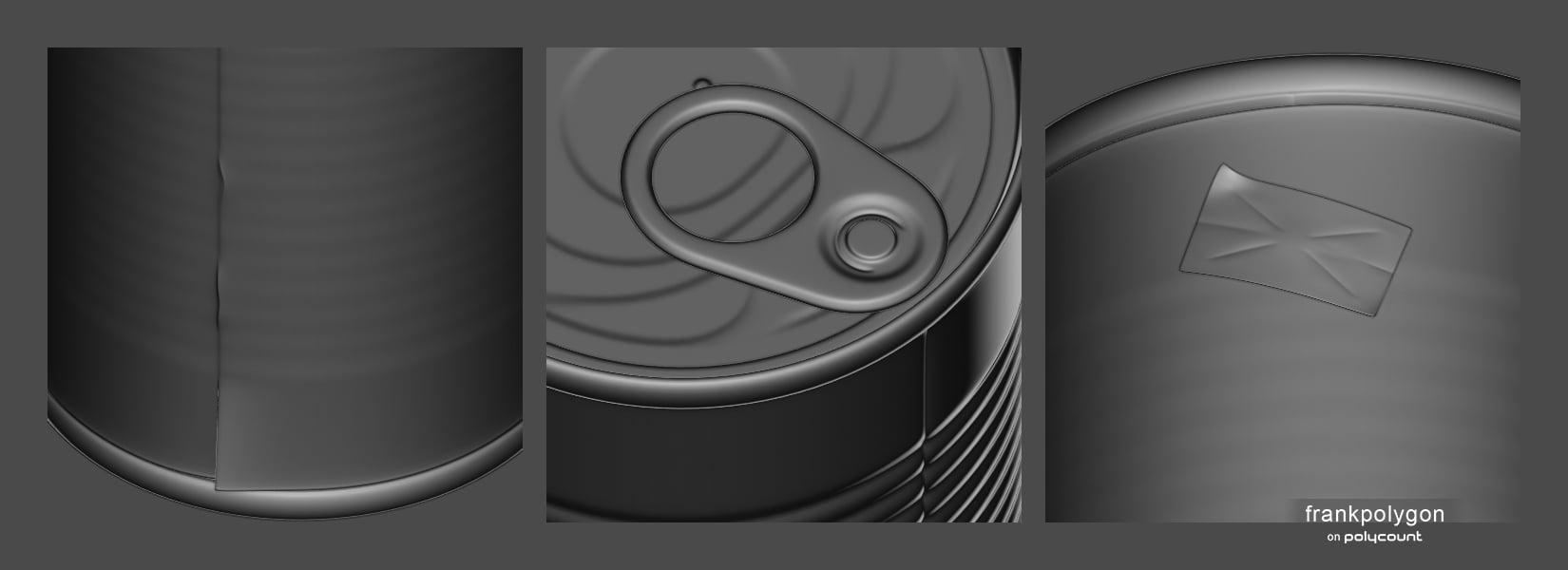

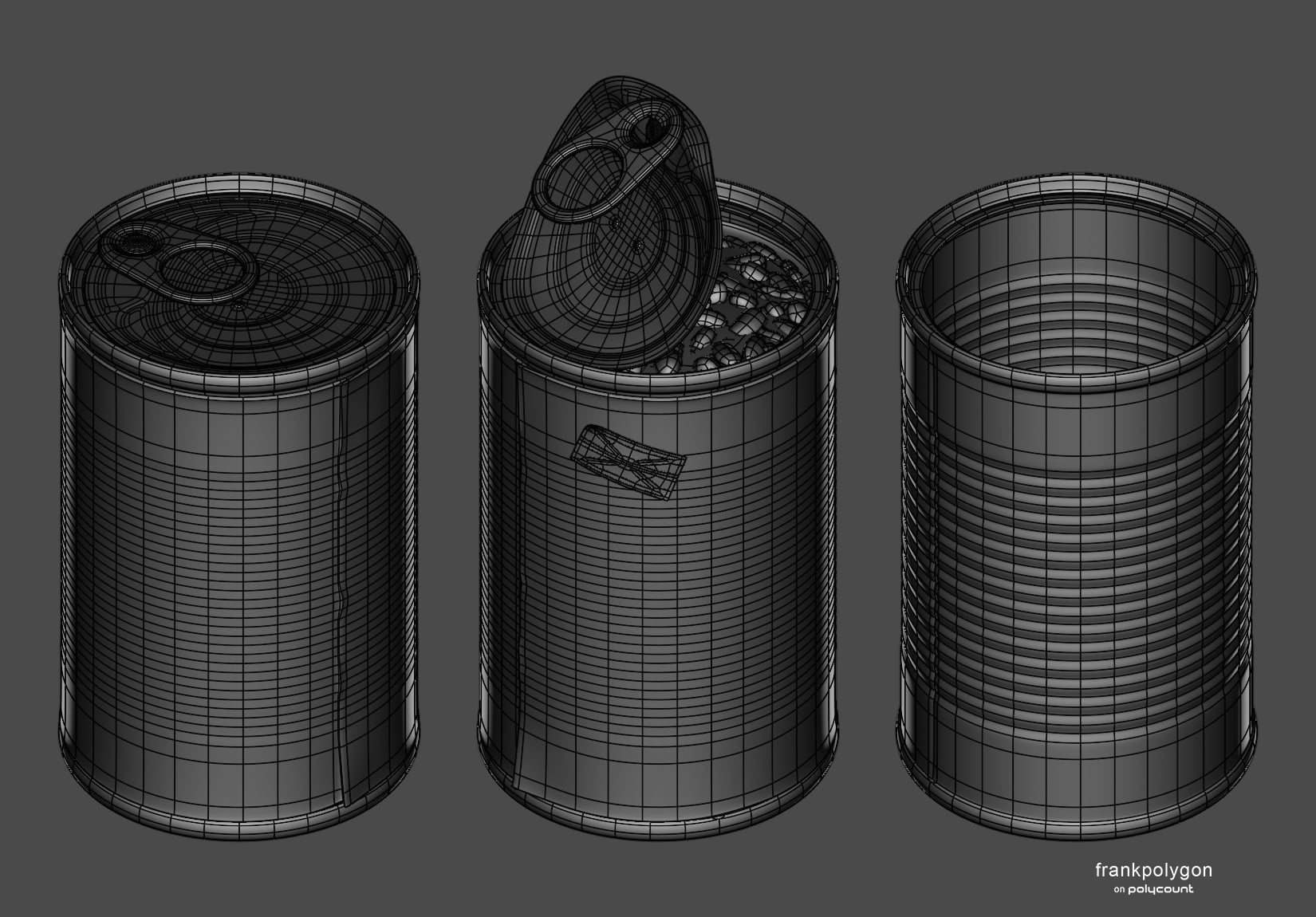

Subdivision sketch: Tin can.

Subdivision sketch: Tin can.

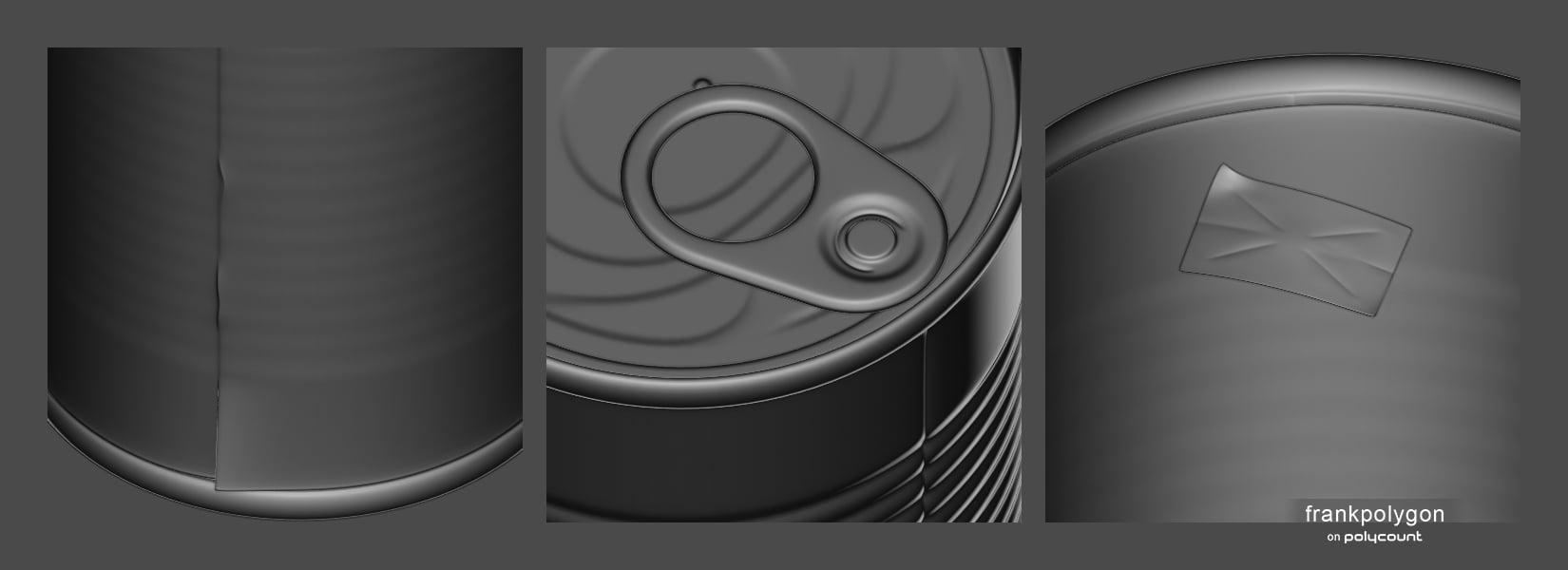

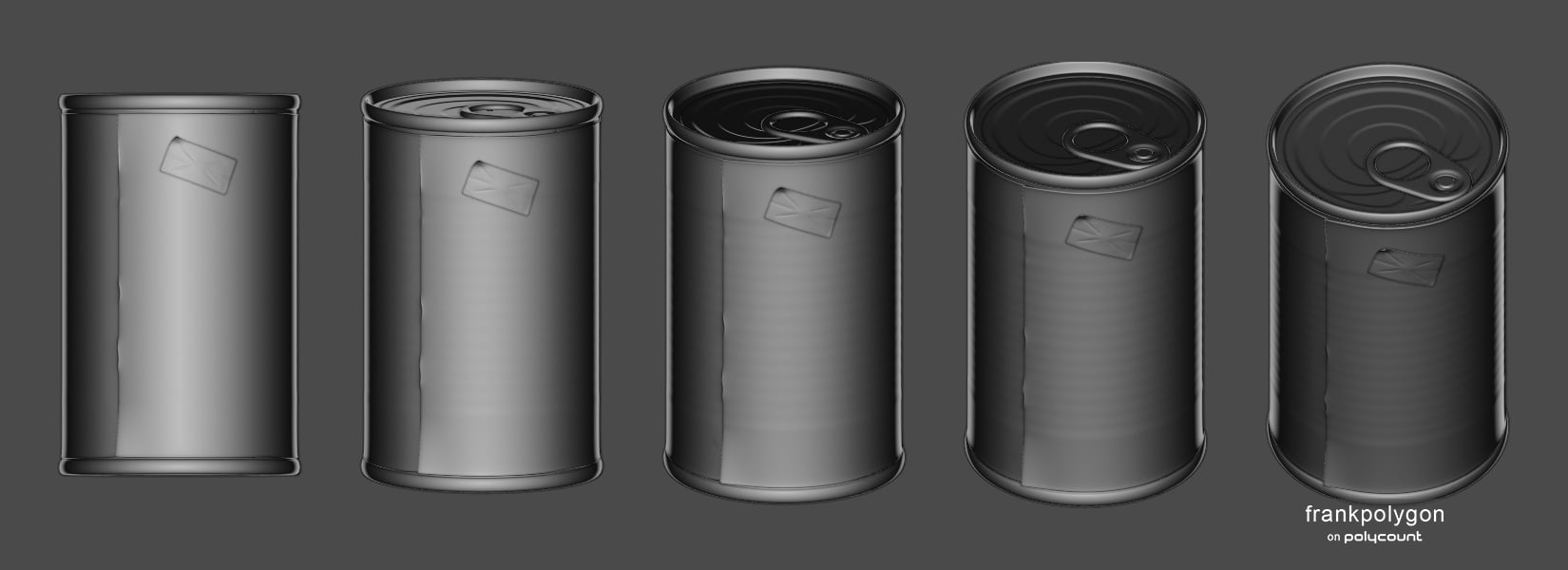

Another food related one. The goal here was to use fairly simple meshes, mostly generated by modifiers, to capture the subtle details using only subdivision modeling. Obviously it's a lot easier to create surface details like this by varying the normal height between layers when texturing. So do that instead of this.

The paper label appears smooth when viewed from most angles but the ribbing on the can shows through when turned.

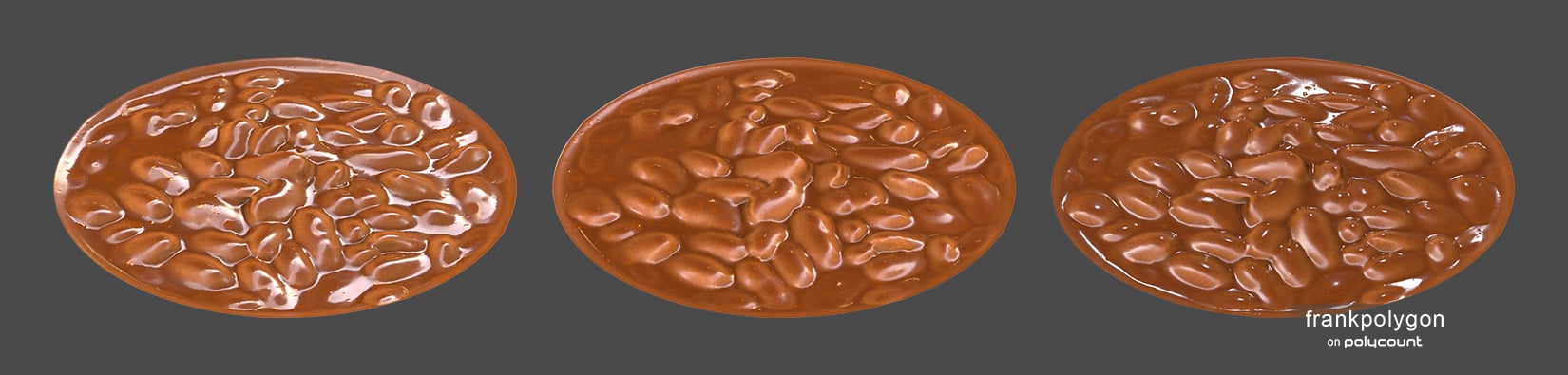

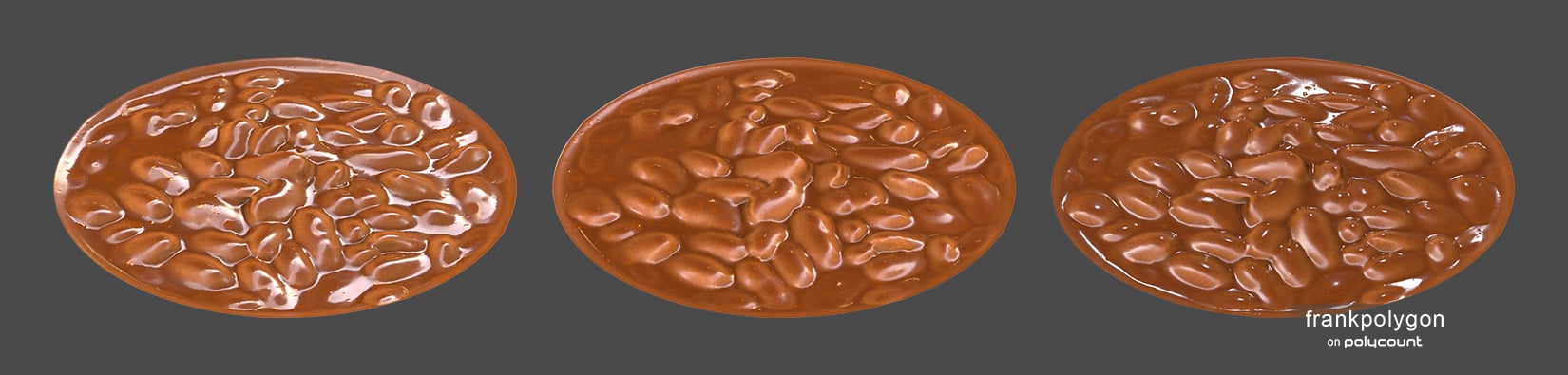

Each bean's size and shape was randomized from a pool of five simple meshes then they were all dropped into a pile using a physics sim. An inset circular plane stands in for the liquid level and meniscus. Everything was shrink wrapped to create a low poly mesh then the high poly baked down to a corresponding normal map. There's too many different styles of baked beans to choose from so the basic material tests ended up being a sort of middle ground.

For a typical game asset: a lot of these surface details can be added during texturing and shouldn't be modeled into the high poly like this.

The final wire frame makes everything look more complicated than it actually is. Most of the meshes are single sided, mirrored, solidified, and based on block outs driven by simple edge and vertex profiles. Many of the support loops are automatically generated with bevel / chamfer modifiers.

A case of can Vs should if there ever was.

6 ·

(PAID) Want to hire Character Artist to design 3D Printable custom miniature

Hi all,

The beloved manager of our local Warhammer store has been promoted to a regional position, and a group of us want to get him a custom miniature for Christmas. The character is going to be of his favorite literary character, Sabriel, from the Old Kingdom series (reference images attached).

What we would like:

- 1:12 scale 3D model of Sabriel the Abhorsen (8-10 inches real height)

What we can pay:

We have a few people who have committed to put some money down for this project, so our budget is in the high hundreds of dollars (but probably not the thousands of dollars). Our priority is the quality of the model, not the bottom line. Plus we're Warhammer players, we're used to paying big money for good plastic.

We will handle the printing and painting of the model ourselves, we just would like a deliverable file.

Thank you for your time!

The beloved manager of our local Warhammer store has been promoted to a regional position, and a group of us want to get him a custom miniature for Christmas. The character is going to be of his favorite literary character, Sabriel, from the Old Kingdom series (reference images attached).

What we would like:

- 1:12 scale 3D model of Sabriel the Abhorsen (8-10 inches real height)

What we can pay:

We have a few people who have committed to put some money down for this project, so our budget is in the high hundreds of dollars (but probably not the thousands of dollars). Our priority is the quality of the model, not the bottom line. Plus we're Warhammer players, we're used to paying big money for good plastic.

We will handle the printing and painting of the model ourselves, we just would like a deliverable file.

Thank you for your time!

Steve

4 ·

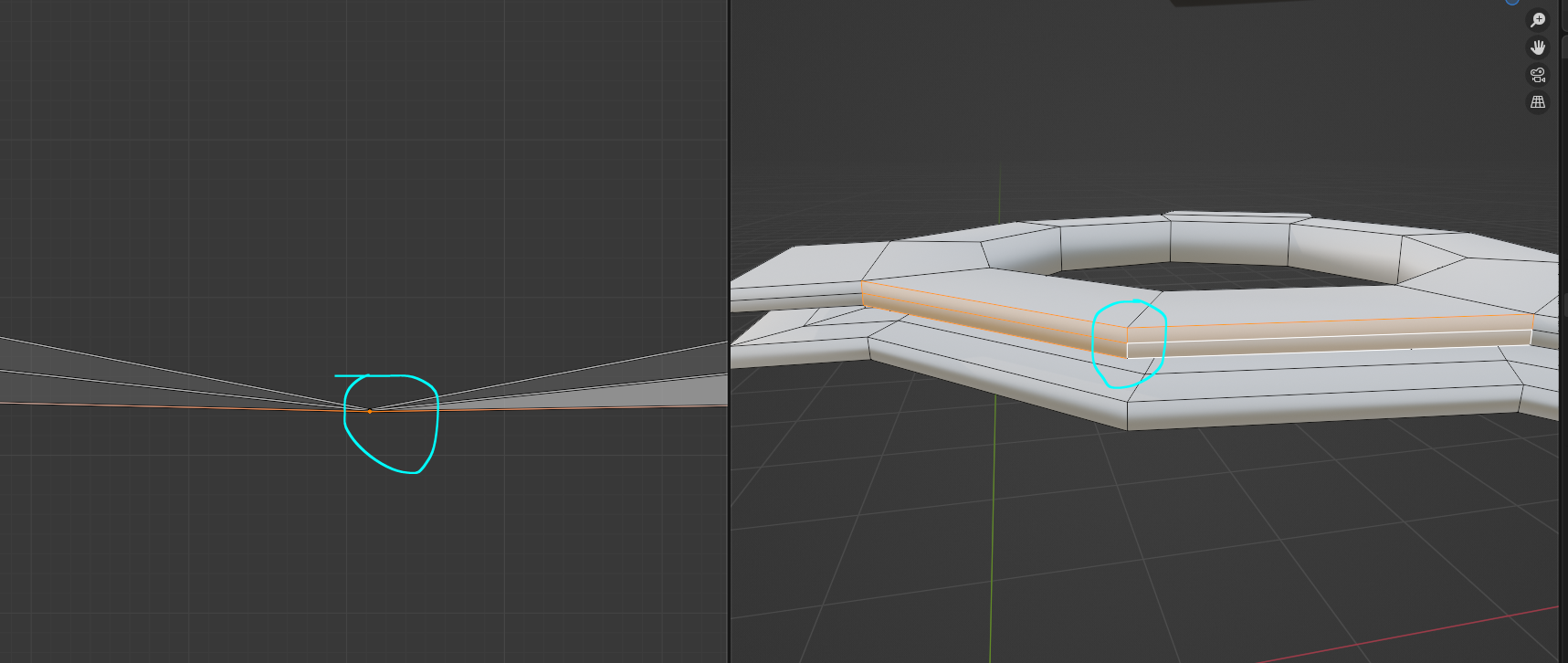

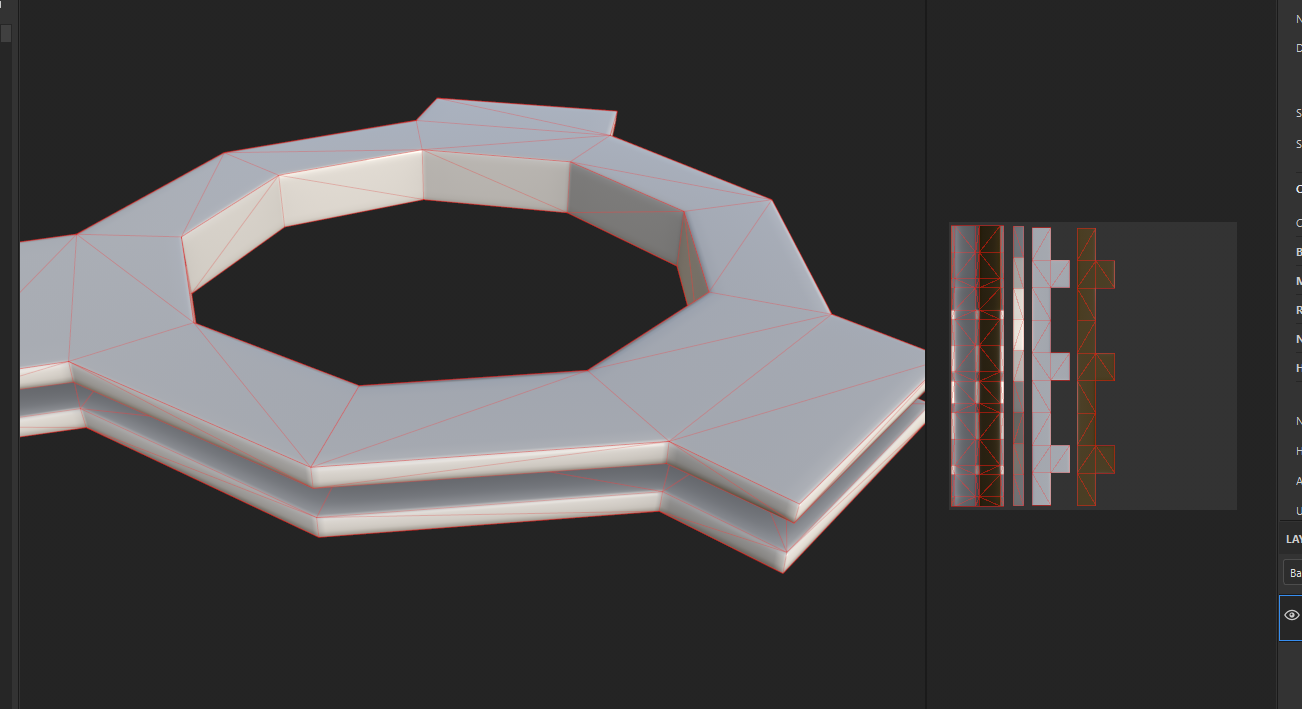

Re: Persistent triangulation artifacts on surface bake. Need help.

Yes, certainly helped

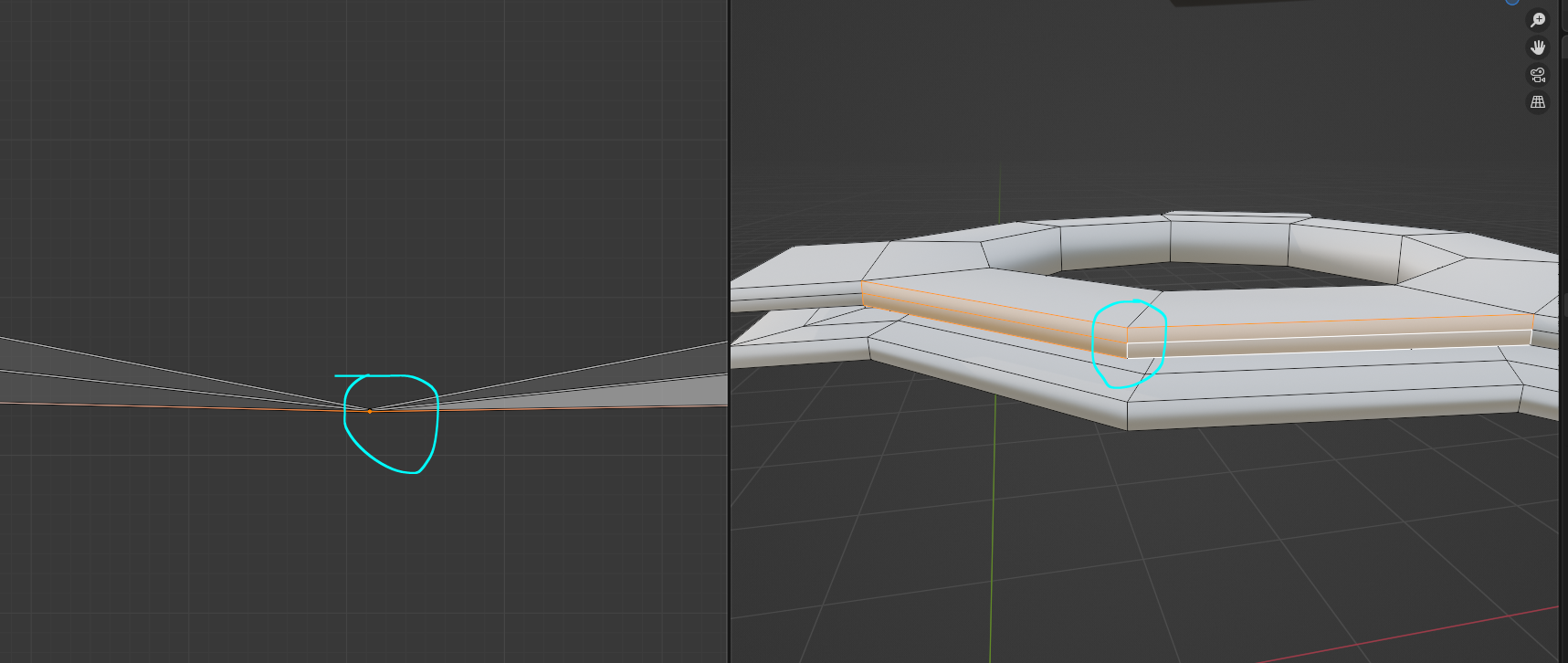

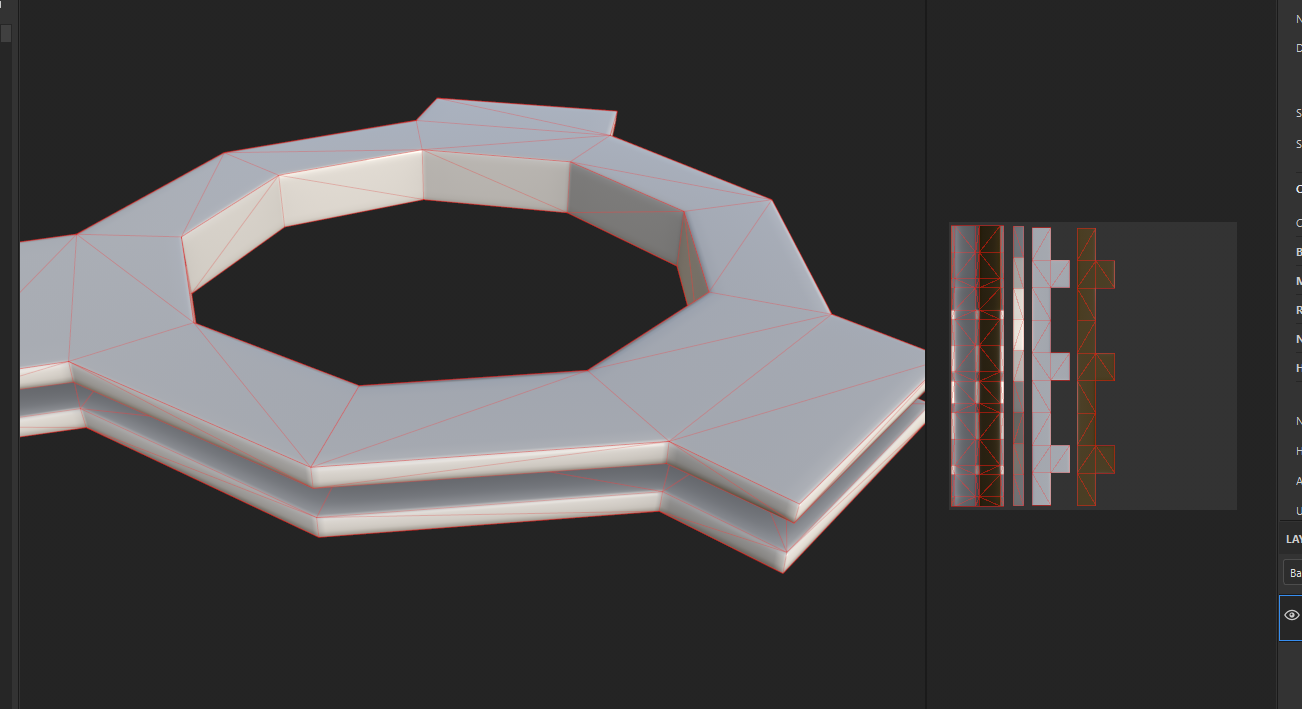

Checking the file, this issue comes from the UVs. Those edges are unwrapped very unevenly, not occupying any UV space in some areas.

I would try something like a cylindrical unwrap (caps, sides) and make the edges at UV borders hard, since they're 90 degrees, to reduce mesh shading gradients. Then I would straighten the UVs to minimize aliasing along seams, even though it means UVs will have some distortion. Test in Painter:

Attached you find the lowpoly being used (perhaps scale is off due to my fbx export setting).

I would note the highpoly has some shading gradients which will show in the baked normal maps.

Checking the file, this issue comes from the UVs. Those edges are unwrapped very unevenly, not occupying any UV space in some areas.

I would try something like a cylindrical unwrap (caps, sides) and make the edges at UV borders hard, since they're 90 degrees, to reduce mesh shading gradients. Then I would straighten the UVs to minimize aliasing along seams, even though it means UVs will have some distortion. Test in Painter:

Attached you find the lowpoly being used (perhaps scale is off due to my fbx export setting).

I would note the highpoly has some shading gradients which will show in the baked normal maps.

Fabi_G

Fabi_G

4 ·

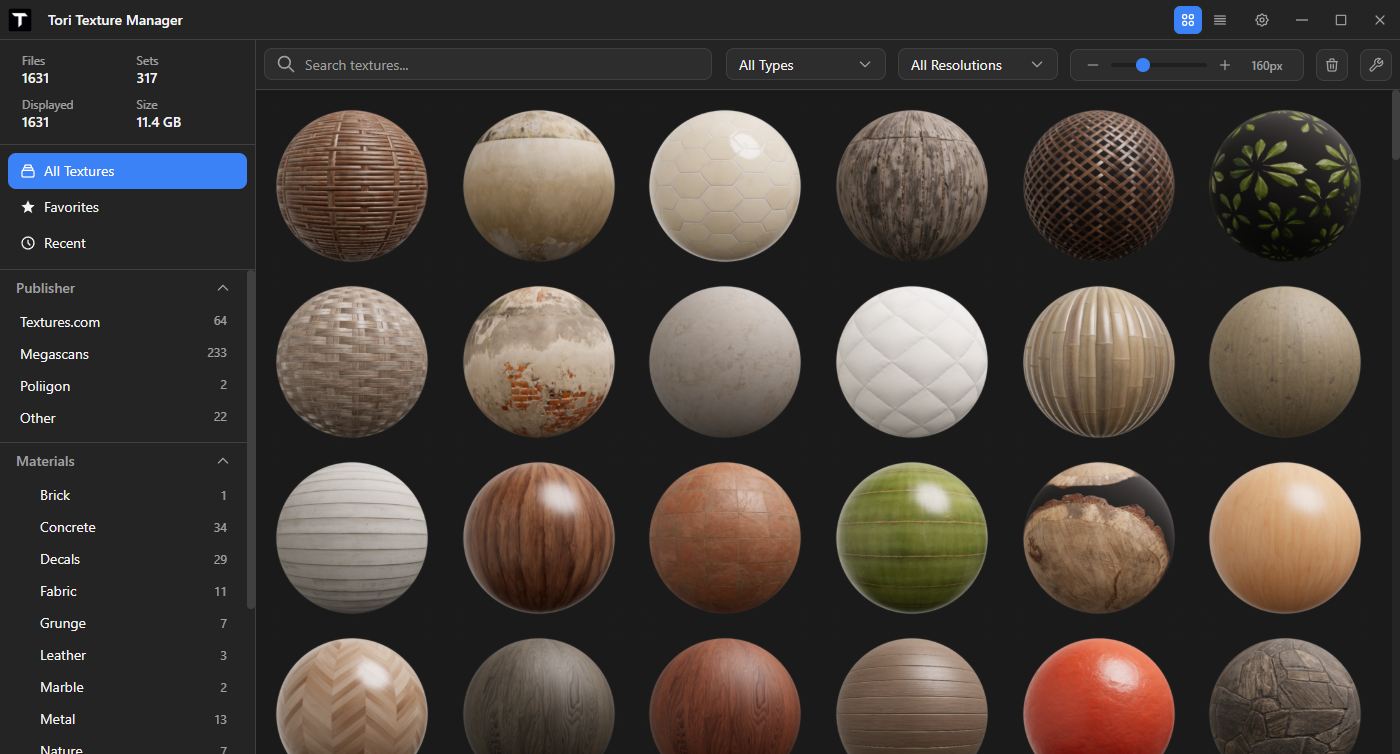

Free Texture Managment Tool - Tori

Hello. I had to finally clean up my texture library mess and of course ended up creating an app for it. Free to use - let me know what you think and if it works for you. Happy to fix bugs and add new features! Hope it's useful!

basics ( link, import, organize ) - https://shapewise.xyz/tori/tori_basics_01.mp4

settings walk through - https://shapewise.xyz/tori/tori_walk_through.mp4

Cheers!

3 ·

Re: What Are You Working On? (3D) 2026

Messing with layered procedural shaders in Blender. could do the same thing in subtance, but at least here I can do it procedurally before I have to bake them down. far from great , but I have just started really

I guess that subtance works with meshes without fully finished uv's , using tri planar projection or similar

I guess that subtance works with meshes without fully finished uv's , using tri planar projection or similar

Ruz

Ruz

3 ·

The Bi-Monthly Environment Art Challenge | March - April (101)

Welcome everyone to the 101st Bi-Monthly Environment Art Challenge for the months of March and April!

This challenge is a way for real-time 3D artists to test their skills and create a piece of work based on concepts provided. It's open to those of all skill levels and we do our best to provide meaningful feedback along the way so everyone can come away from the challenge with actionable points on which they can improve their craft!

- ENVIRONMENTS -

HARD SURFACE ENVIRONMENT:

The Forgotten Industry by Abrar Khan

https://www.artstation.com/artwork/9EXmdo

https://www.artstation.com/artwork/9EXmdo

STYLIZED ENVIRONMENT:

Urban Sewer Background Painting - 03 by Adrien Gonzalez

https://www.artstation.com/artwork/x3GrOO

https://www.artstation.com/artwork/x3GrOO

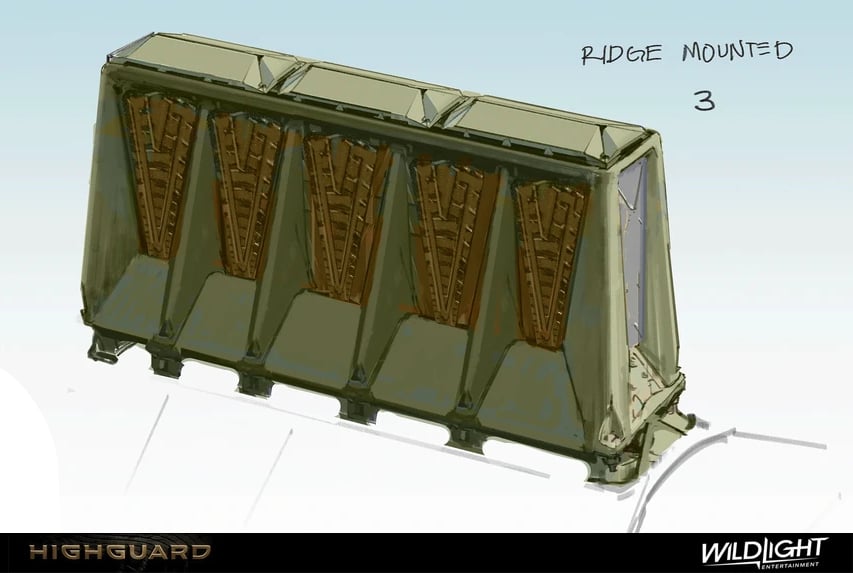

- PROPS -

HARD SURFACE PROP:

Battlefield 6 - Deployable Cover Concept Design by Joakim Englander

https://www.artstation.com/artwork/YGDkAX

https://www.artstation.com/artwork/YGDkAX

STYLIZED PROP:

Early Props + Exploration by Gabriel Miura Brandt

https://www.artstation.com/artwork/nJnLP1

https://www.artstation.com/artwork/nJnLP1

- RULES -

Please read all the rules before starting:

- Try to post at least one critique for every post that you make. This will make for a better learning environment and help us all grow as artists.

- Try your best to finish as much as you can in the time frame provided, but remember even if you don't finish by the end of the challenge we encourage you to keep pushing and finish your piece!

- Post what you are working on in this thread so that way it's a more centralized place for advice and critique. Please avoid creating a new thread as we don't want to spam out the forums.

- It is recommended to use a game engine to present your work. Unreal Engine, Unity, and Godot are very common engines that can be used but feel free to use any alternatives that you want.

- 3D Viewers (Sketchfab, Marmoset Viewer, etc) are welcome, but please note that their contents can be stolen by those who know how. Please ensure you're comfortable with this potential before using one.

- Feel free to change up your chosen concept a bit if you want! Interpret these concepts to your liking, especially if your aim is to add storytelling elements.

- If you finish your project and decide to post it to something like Artstation, make sure you give credit to the concept artist in the form of a link to their profile. Additionally, it is recommended to ask a concept artist for their permission to post a 3D piece based on their work before doing so.

- RECOMMENDATIONS -

- When you are just starting out making a scene, it can seem complicated or imposing. Take your time planning and blocking out, it will set you up for success later on.

- Think about how you can re-use assets, re-use textures, break it down as simple as possible and plan it out. A lot of people will break it down in their own way when they start out their challenge. Gather some reference images as well for different parts of the scene, don't be afraid to make it your own.

- We strongly encourage you to go and look at other games and see how they make their assets as well as get concept art to give it your own feel.

- The goal is to learn and grow both artistically and in your ability to both give and receive critique, but don't stress about it and remember to have fun!

Pinkfox

Pinkfox

6 ·

Re: Anyone remember the Dominance Wars?

If you want to dive back into the spirit of that era you'll get a kick out of the Vertex ebooks, still available to download.

https://ryanhawkins.gumroad.com/

Flipping through them again every now and then over the years it's honestly kind of amazing to see how the internet (and online art communities) have devolved since. At the time of volume 1 the artists all had cool personal websites and were cranking out badass work, free from the worry about "likes", algorithms, and of course blissfully unaware of the upcoming threat of AI plagiarism.

Ryan and everyone involved did such an amazing job with these, incredibly valuable stuff.

https://ryanhawkins.gumroad.com/

Flipping through them again every now and then over the years it's honestly kind of amazing to see how the internet (and online art communities) have devolved since. At the time of volume 1 the artists all had cool personal websites and were cranking out badass work, free from the worry about "likes", algorithms, and of course blissfully unaware of the upcoming threat of AI plagiarism.

Ryan and everyone involved did such an amazing job with these, incredibly valuable stuff.

pior

pior

12 ·

Re: [WIP] Stalker 2 Fan Art - Unreal 5 Realistic Environment & Story Telling

Sharing WIP new updates on my project. I created custom concrete floor textures and modular concrete blocks, and refined the ambiance to strengthen the mood and overall atmosphere.

Still polishing materials, lighting, and storytelling — more updates soo n.

n.

PeterGatchev

PeterGatchev

3 ·

Re: The Bi-Monthly Environment Art Challenge | January - February (100)

refinement pass on the ornaments before final concept matching. Lots of hpolish

3 ·