Best Of

Re: Condemned Hallway [ WIP - C&C ]

In the previous post, I totally missed that I'd bawked the uvs on the wood panels along the wall, which is why they look alot cleaner and low res. 😅

Today I fixed the UV's and also evened out the paint chipping, so now there aren't some panels that are completely stripped of paint and others untouched. Though looking at it now there are a few parts where the paint peeling could look more realistic. I also made a few more here and there.

And I added some vertex painting to break up some of the clean edges on the peeling wallpaper. After some feedback, I boosted the sunlight so it's now overexposed and looking a bit more realistic.

iansmithartist

iansmithartist

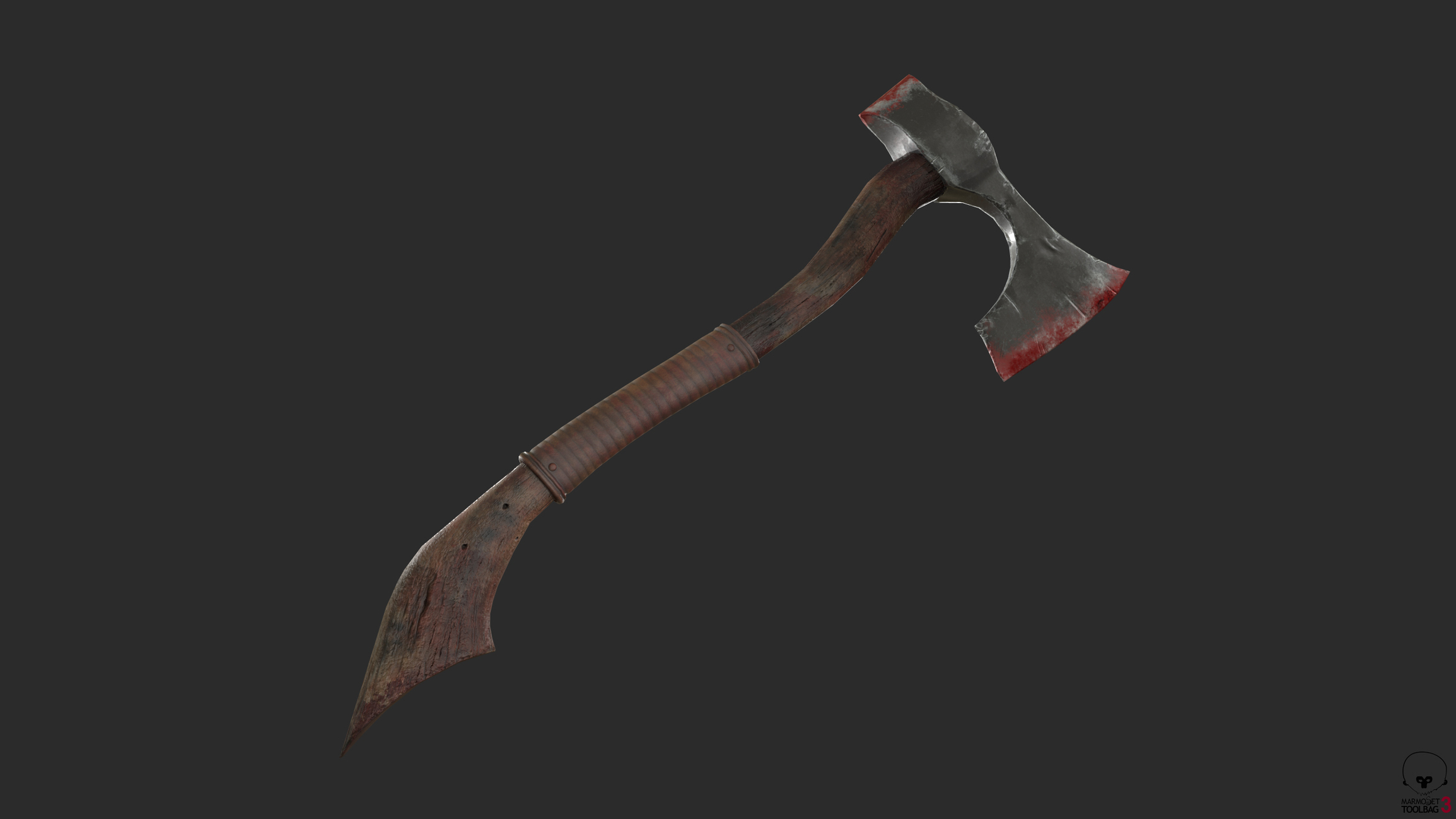

Viking Axe

axe vikings

Viking Axe

non-profit work

Personal project

geometry 1886 tris

visualization in Marmoset 3

textures in substance painter

you can twist the model and see the details

zakazchik81

zakazchik81

Re: How The F*#% Do I Model This? - Reply for help with specific shapes - (Post attempt before asking)

@Laon A few posts up, there's a couple of relevant examples that cover how to use segment matching to connect a cylinder to a curved surface and how to route the topology around the base of a cylinder that connects to an angled surface. The basic principles of these fundamental modeling strategies can be combined to resolve most of the potential issues when creating objects with similar shapes.

Start the block out using shapes with a relatively uniform segment length then line up the intersecting edges by adjusting the number of segments in both shapes. Since the radial features are evenly spaced, it's also important that the number of segments in the larger cylinder be divisible by the number of smaller holes. Dividing the object into mirrored, tileable sections will also help make the whole modeling process more efficient.

The segment matching should be reasonably close but doesn't need to be perfect. A boolean operation can be used to create the smaller hole then any stray vertices can be merged down to clean up the mesh. Additional loop cuts, that run perpendicular to the cylinder wall segments, can be added to resolve any n-gons or triangles back into quads.

Support loops around the major shape transitions can be added with a single bevel / chamfer operation. Subdivide and check for visible smoothing artifacts, before splitting the mesh and copying the tileable section. Filling in the rest of geometry on the flat part of the cylinder cap is fairly straightforward and has been omitted for clarity.

The quantity, size and spacing of the holes will all affect the segment matching. Using too many segments can make the mesh difficult to edit and too few segments can cause undesired deformation. It's also possible to merge some of the support loops into the existing geometry on the larger cylinder but this can produce noticeable smoothing artifacts when it disrupts the accuracy or consistency of the shapes. The key is to balance accuracy and efficiency.

This thread is full of visual examples and written documentation that covers most common modeling challenges. Though it isn't always possible to find an example of a particular object, there's often very good examples of similar shapes and a lot of the modeling fundamentals are the same. Breaking a complex problem down into individual parts and looking for similar examples then testing those solutions is a significant part of the learning process. Even a quick skim over this thread is usually worth the time.

Recap:

- Use segment matching to line up the topology around complex shape intersections.

- Split repetitive surface features into tileable sections.

- Look for similar problems and test those solutions.

Addendum:

Alternate topology layouts, that route the loop flow around the shape intersection, can be used to get around matching the segments on both shapes but this can introduce subtle smoothing artifacts. These smoothing artifacts tend to be especially noticeable in areas where the topology changes alter the shape of the underlying surface or where poles are are left unconstrained in the middle of a curve.

This is generally workable on matte surfaces or when using normal overlays with lots of high frequency noise but these subtle smoothing errors will be noticeable under certain lighting conditions and when using materials with high gloss or reflectance values. The less geometry used to support the shapes, the more pronounced this type of artifact will tend to be. When modeling certain types of high quality surfaces, it's generally a good idea to run a flow check to ensure that the topology isn't going to causes issues with reflective materials.

In the first example below: The highlighted quad is an area where the change in topology deforms the curvature of the underlying shape and pushes the adjacent pole out into the middle of a curved surface. These two issues generate both a minor smoothing artifact below the corner of the shape intersection and a rippled distortion in the surface flow around the hole.

In the second example below: matching the segments of both the large and small shapes will help keep the poles close to the support loops on the shape intersection. Which allows the existing geometry in the basic shapes to constrain any potential smoothing artifacts to a smaller area and also helps preserve uninterrupted surface flow.

Limiting the amount of deformation caused by the modeling operations, used to make abrupt changes in the topology and constraining poles near or between well supported areas will also help minimize the appearance of most smoothing artifacts.

Below is a brief example of how the topology flow on the previous example can be simplified without deforming the underlying surfaces. Locate an alternate set of edges in the larger shape then select and dissolve the extraneous support loops. Join the loop flow around the intersecting shape to the loop flow and base geometry of the larger shape. The final mesh is a bit cleaner and free of any major smoothing artifacts. Though the sharpness of the edges around the corner of the shape intersection does vary slightly.

Re: How do I create elastic and taut meshes?

Good advice.

Just to illustrate and briefly add to what's already been recommended: simple elastic and fabric components can generally be created with some basic subdivision modeling. Keeping things relatively simple and letting the subdivision smoothing do most of the work is what makes this process more efficient. Using modeling operations that synchronize the relative movement of adjacent mesh components or insert new loops, along an arc between two existing points, will help keep the surface flow of the whole mesh relatively even. Tools like bridge, loft, proportional edit, soft selection, path deform, latice, FFD, etc. can be used to speed up the workflow.

There's also more than a few different ways to approach the modeling process. Here's a couple of workflow examples. One approach is to model the end points of the shapes individually, rotate them into position then connect them with a modeling operation that will insert new geometry in an arc between the two shapes. An alternate approach would be to model the entire shape flat then move it into position using a curve or lattice based deform operation.

Below is an example of what the process could look like when modeling the end points first then connecting the shapes. Start by establishing the basic shape profile and topology of the end points. Rotate and deform the open end of the shape, with proportional editing fall off enabled, to fit the underlying surface. Bridge the edge loops at the open end of the shape and adjust the arc between the shapes until it looks appealing. All of these modeling operations are done on a single sided mesh to keep things simple. Mesh thickness and support loops are added with solidify and bevel modifiers, respectively.

Below is an example of what the process could look like when modeling the entire shape flat and deforming it along a curved path. Start by establishing the shape's entire profile and topology layout. Add mesh thickness with a solidify operation. Insert a curve and adjust the shape so it creates a smooth path between the two anchor points for the strap. Deform the strap along the path and add support loops with a bevel operation.

Recap:

Keep things simple when blocking out the shapes. Use tools that can deform or generate geometry along an arc between two points. Rely on the subdivision to smooth everything out.

Additional resources: below is a link to a more in-depth look at using a similar process for stiff fabric components of hard surface models.

https://polycount.com/discussion/comment/2771257/#Comment_2771257

Re: The Bi-Monthly Environment Art Challenge | July - August (79)

Looks good for the short amount of time!

I think the main difference between the concept art and what you got so far is actually the colors. In the concept the white pops way more also because it has this nice red/ochery tint, especially in the water canal. The ocean gives this great dark blue contrast (I know you already said you're not happy with the water yet) and the cliffs in the bottom left (and middle island) are redish. I think what could help you a lot is some sort of warm light coming from the camera. The cliffs and left white wall are in the shade yes but they get alot of ambient light in the concept. Also your left white wall is prettty blue, especially at the top - a warm light from said direction could maybe help out in that regard as well.

Overall the far away island takes the focus in your render because it is rather bright and your white foreground and left cliff + wall don't pop as much as in the concept. I'd probably fix that first and postpone the foilage part till the end. Instead having the background blurry could help a lot. I'm not an expert with cameras but I think you know what I mean when I say having the focal point closer to the very foreground and keeping the image rather sharp until the middle cliffs/island between the boats and slowly have it blur out more and more until it reaches the distant island.

Edit: And don't be stingy about polys in the foreground! Those corners in the water canal send shivers down my spine haha.

Re: The Bi-Monthly Environment Art Challenge | July - August (79)

Just started this week. Working on getting the composition right.

Re: Show your hand painted stuff, pls!

Hey everyone. Love painting food so I made this !

Twitter here : https://twitter.com/DetectivePacha

https://sketchfab.com/models/e9ea5d3bbdf0498cbcafd6f50cce2c7b/#UNIQSKFBVANILLA

TinyPacha

TinyPacha

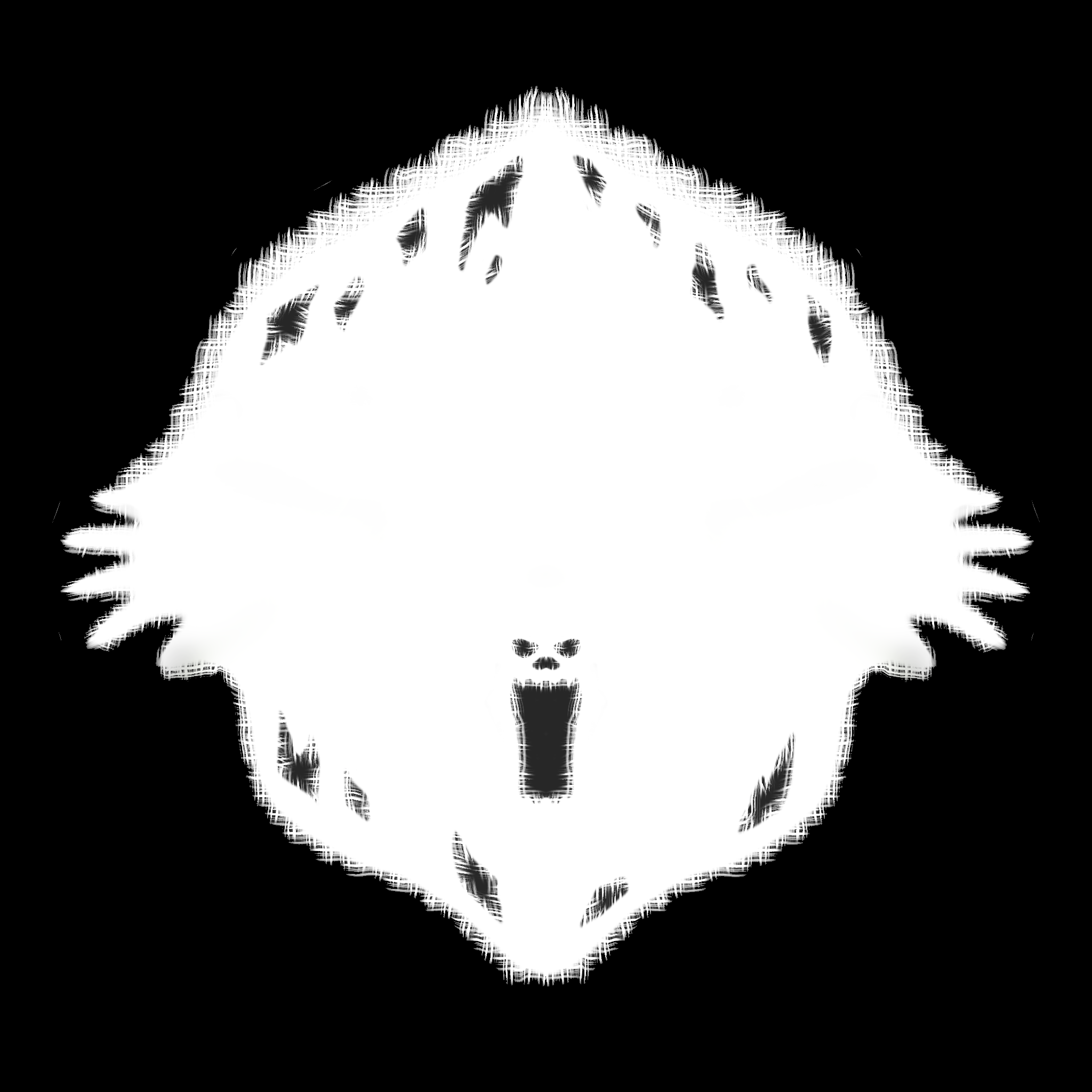

Glowing Sheet Ghost

Hi my name is Nick, working on becoming a character modeler for video games. This is one of my characters for a simple haunted house game, made using Maya, Zbrush, and Affinity Photo. I would like to hear people's feedback on it.

C&C Please and Thank you!