The BRAWL² Tournament Challenge has been announced!

It starts May 12, and ends Oct 17. Let's see what you got!

https://polycount.com/discussion/237047/the-brawl²-tournament

It starts May 12, and ends Oct 17. Let's see what you got!

https://polycount.com/discussion/237047/the-brawl²-tournament

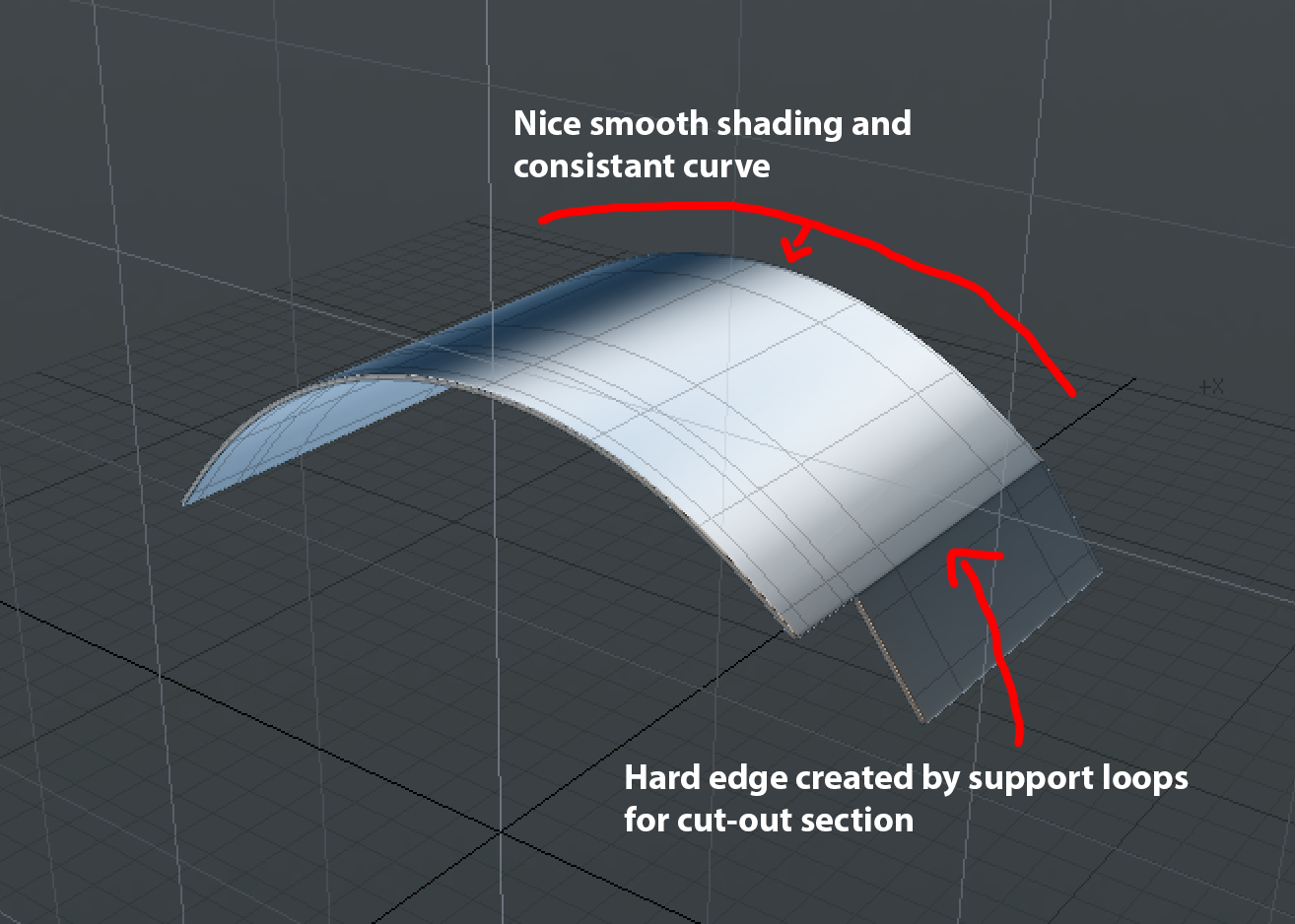

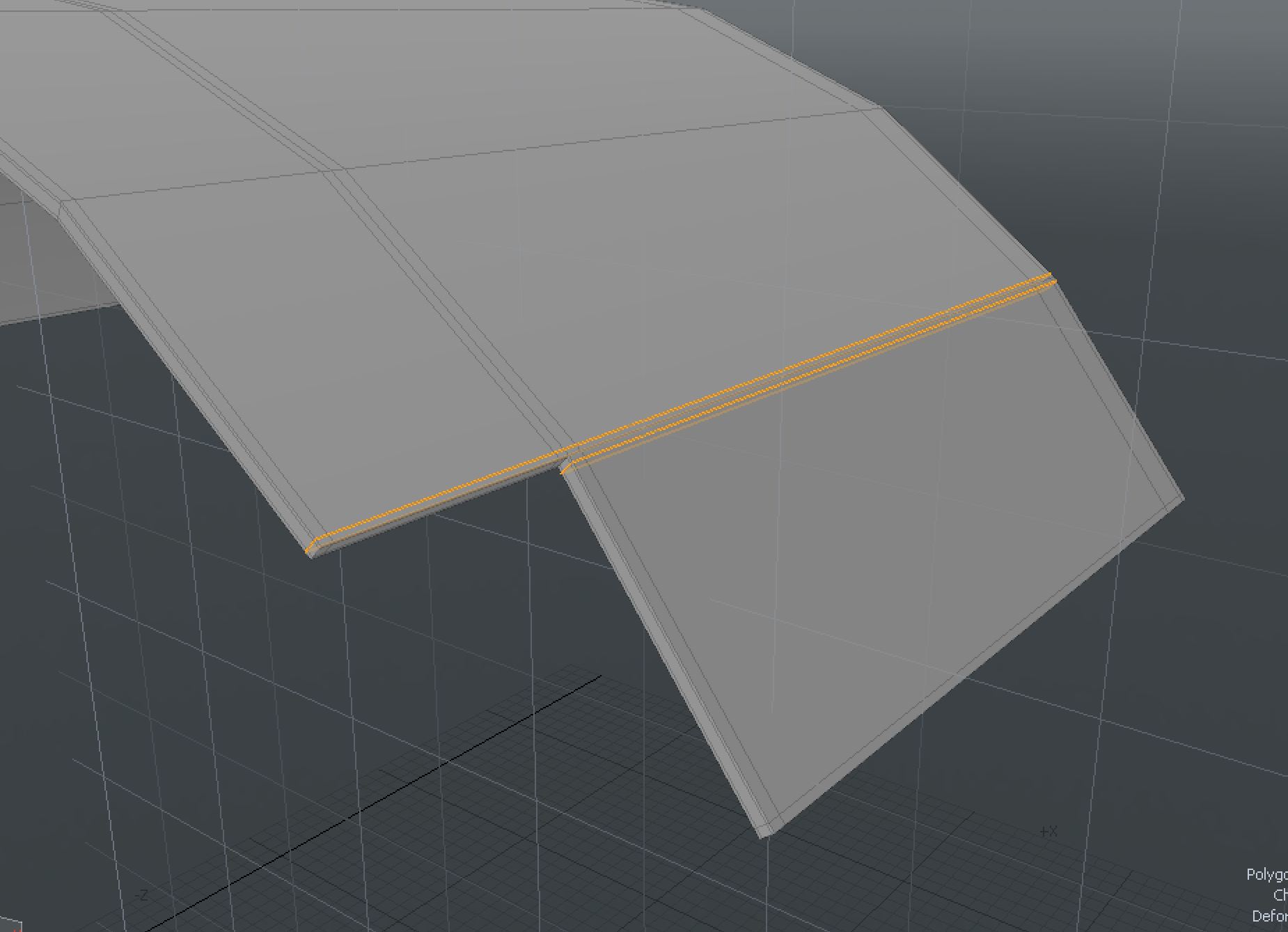

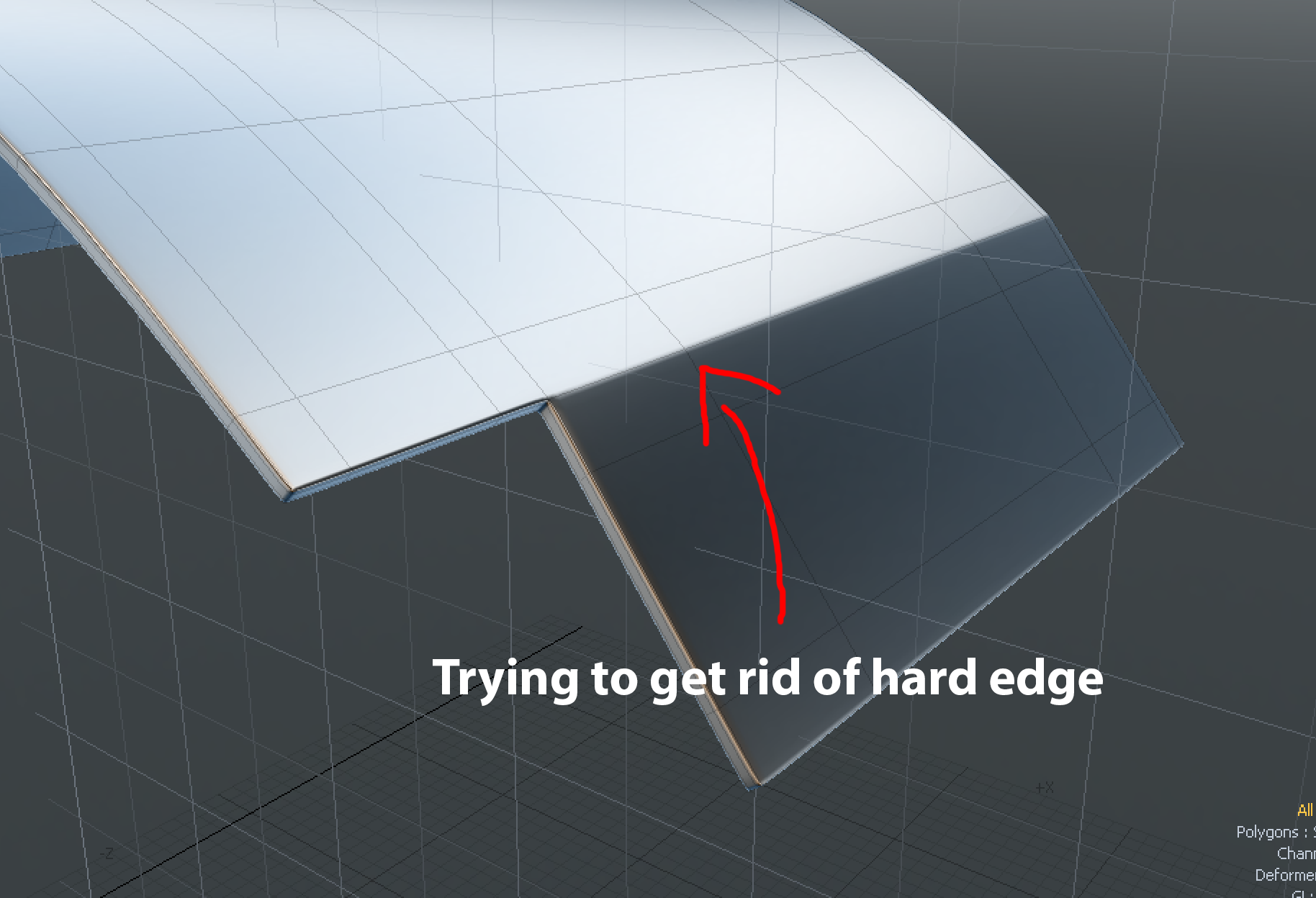

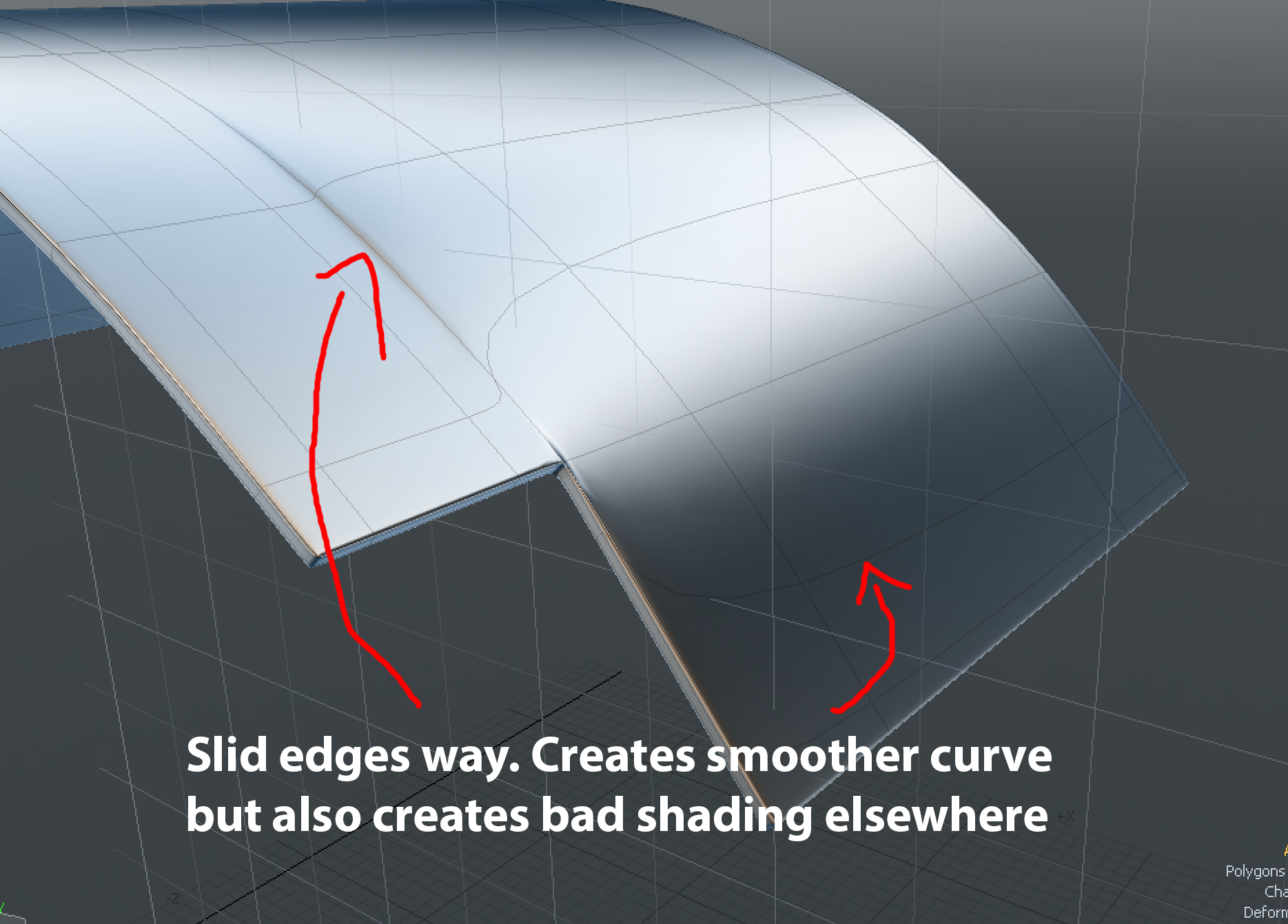

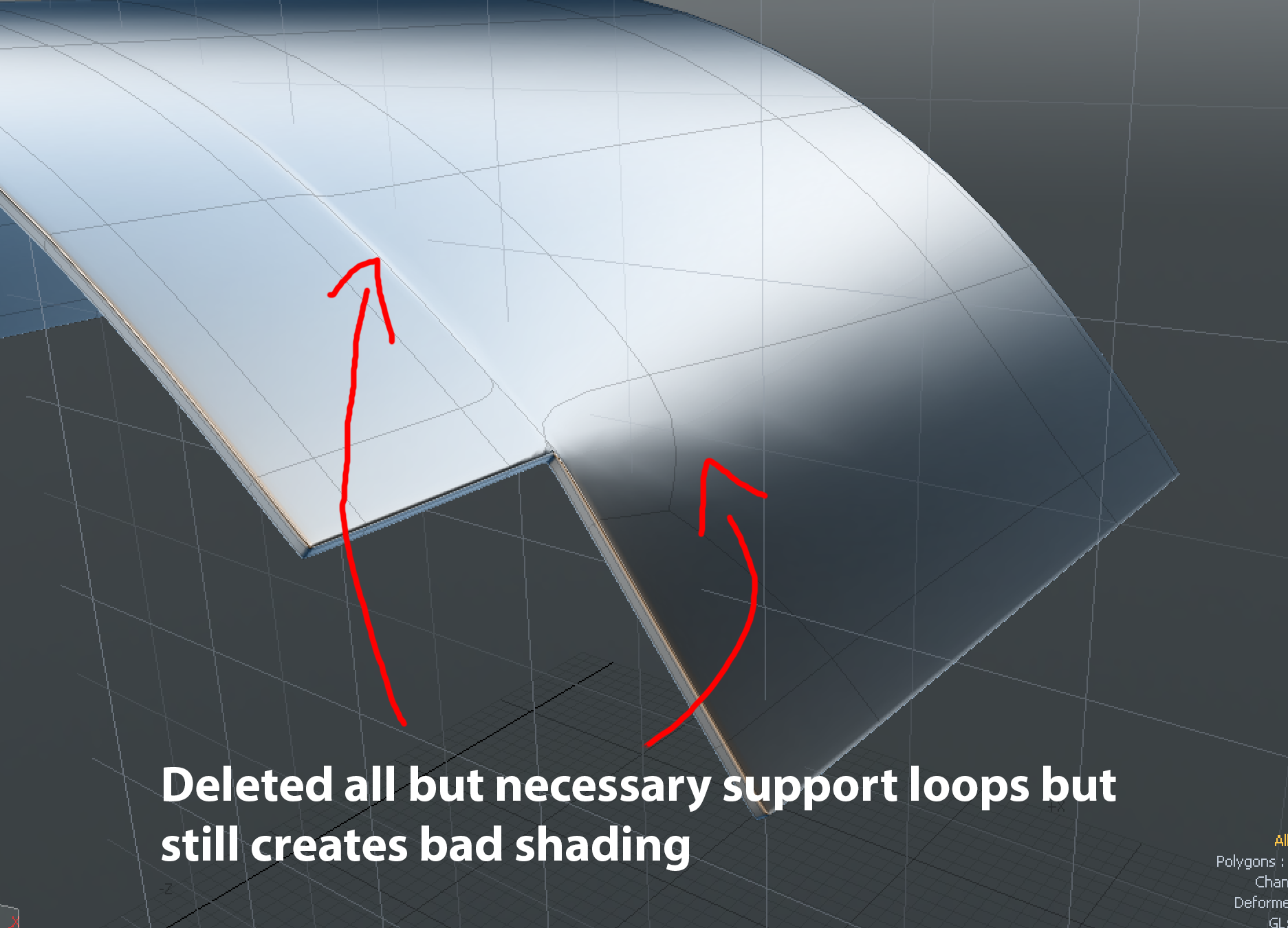

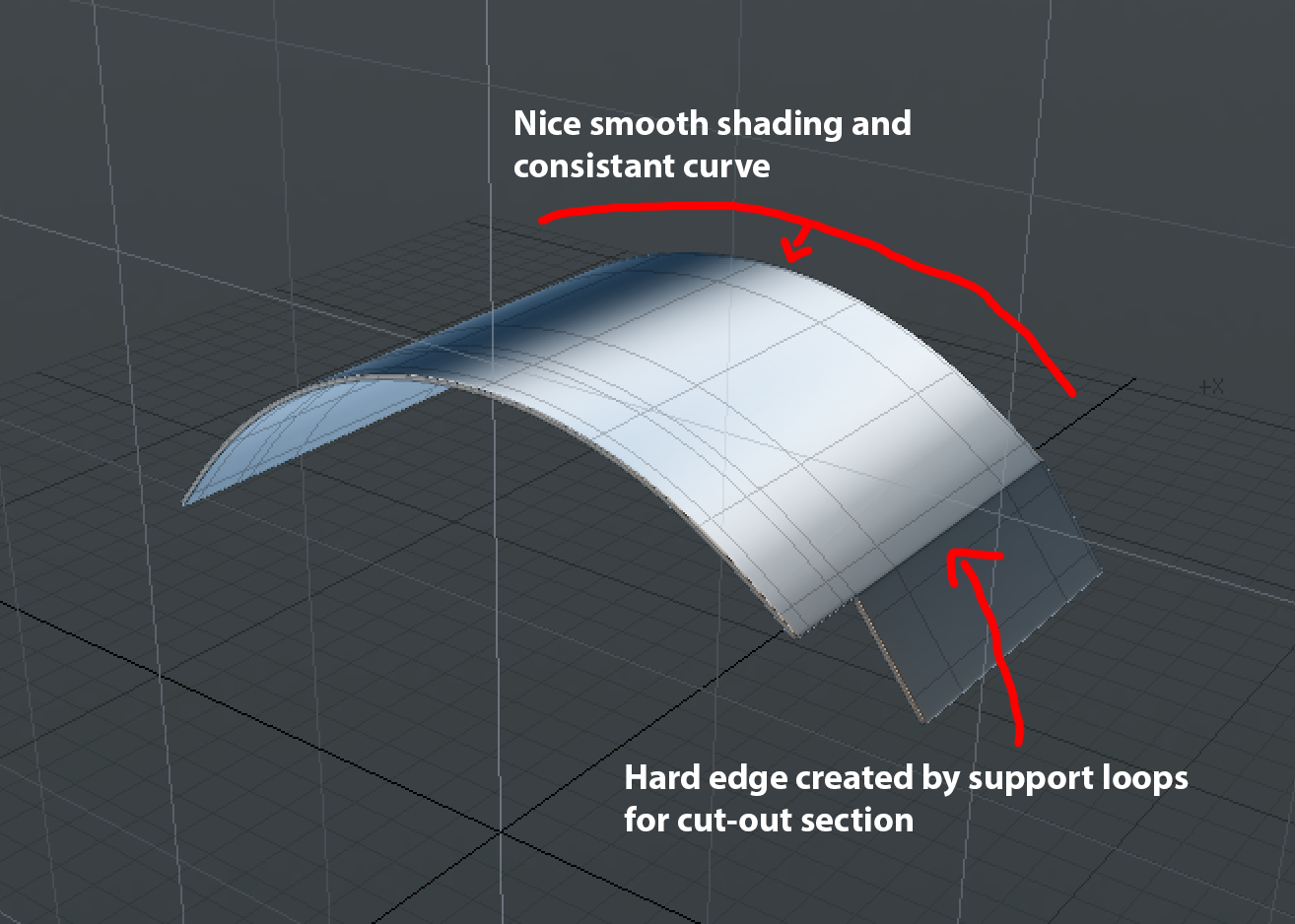

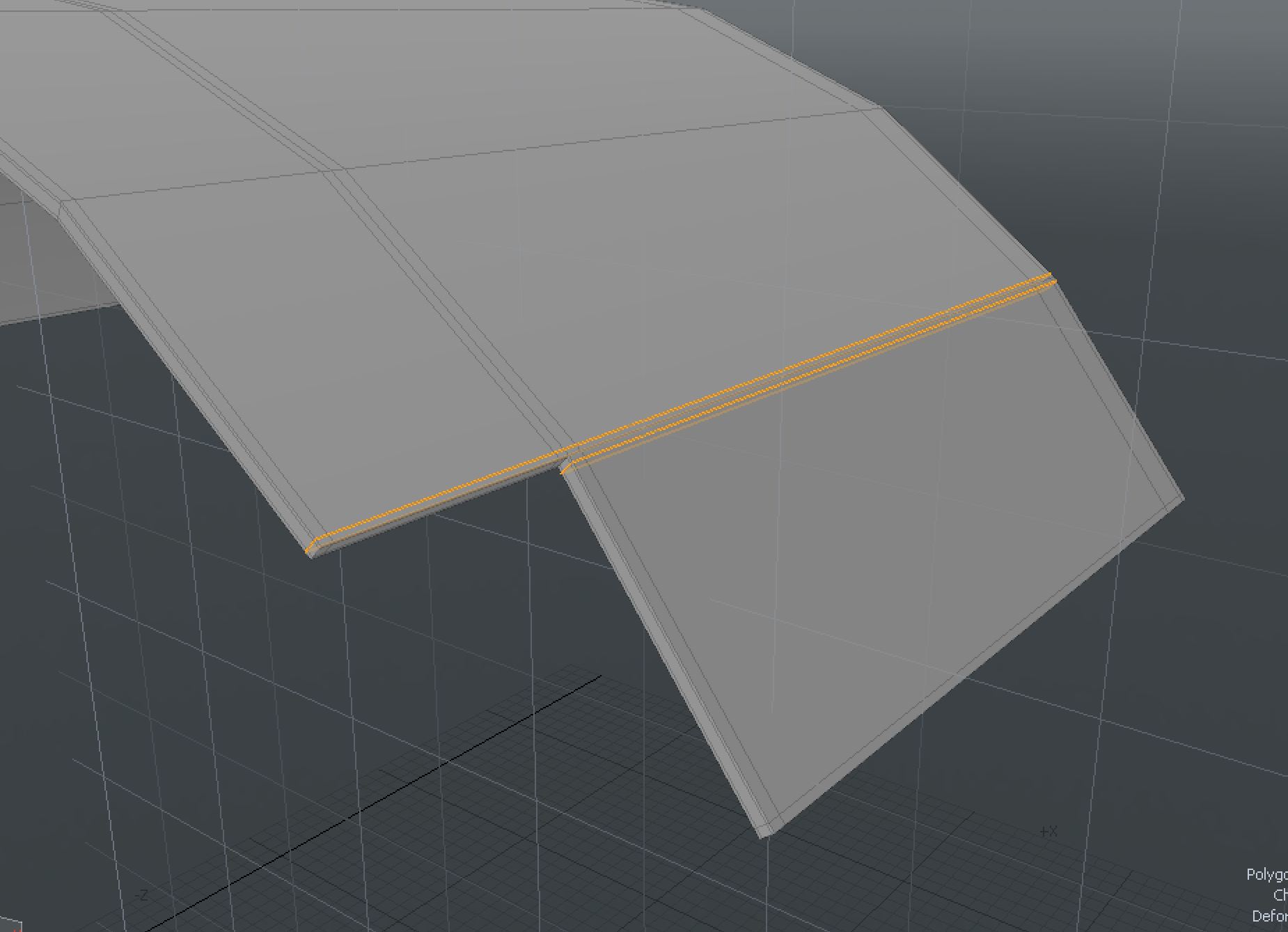

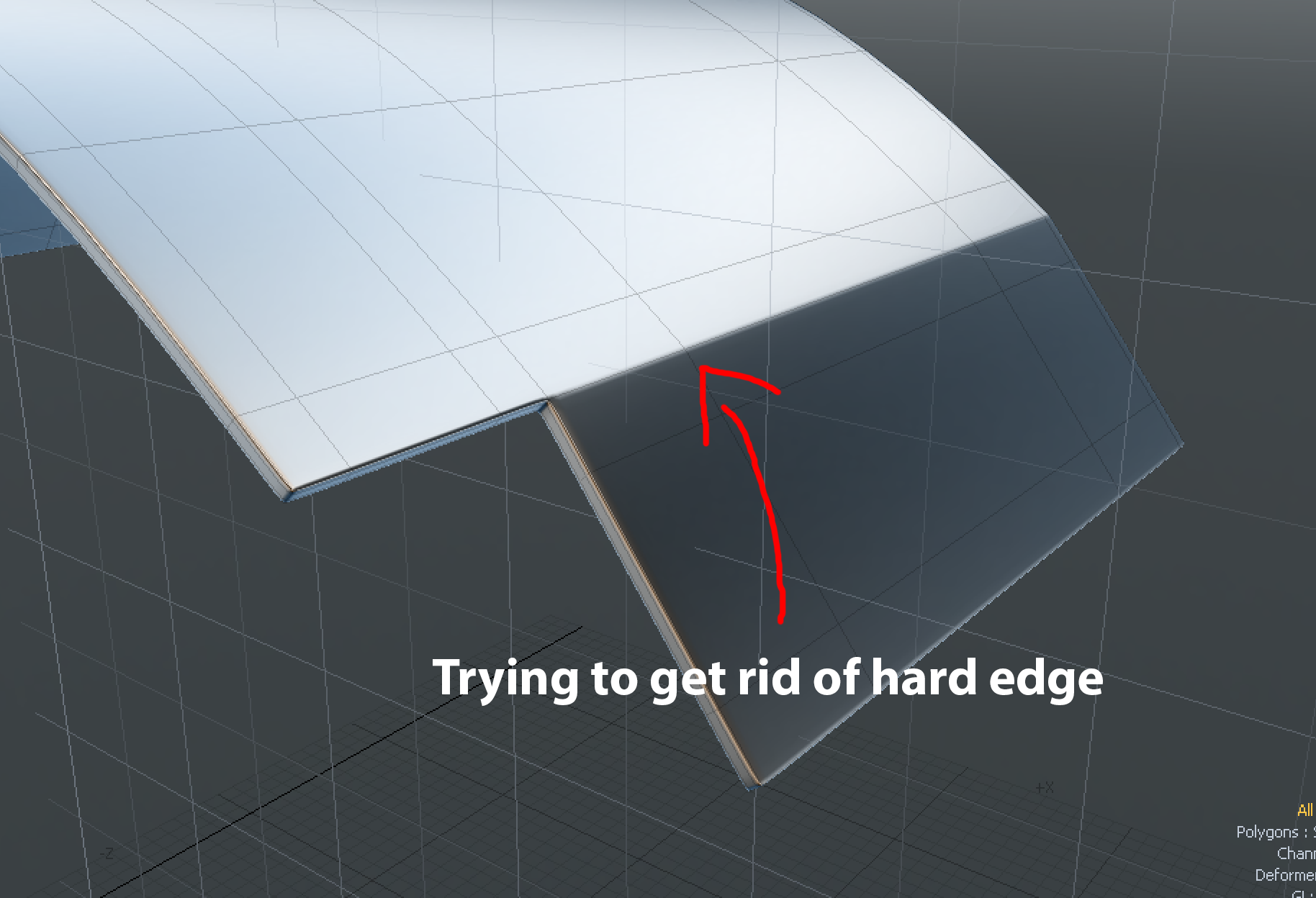

Support loops creating unwanted hard edges

Hey all,

Hoping someone here can help me with a problem I seem to come accross quite a lot and have yet to find an elegant solution to. Apologies if this post is wordy as I find trying to describe this problem a little tricky.

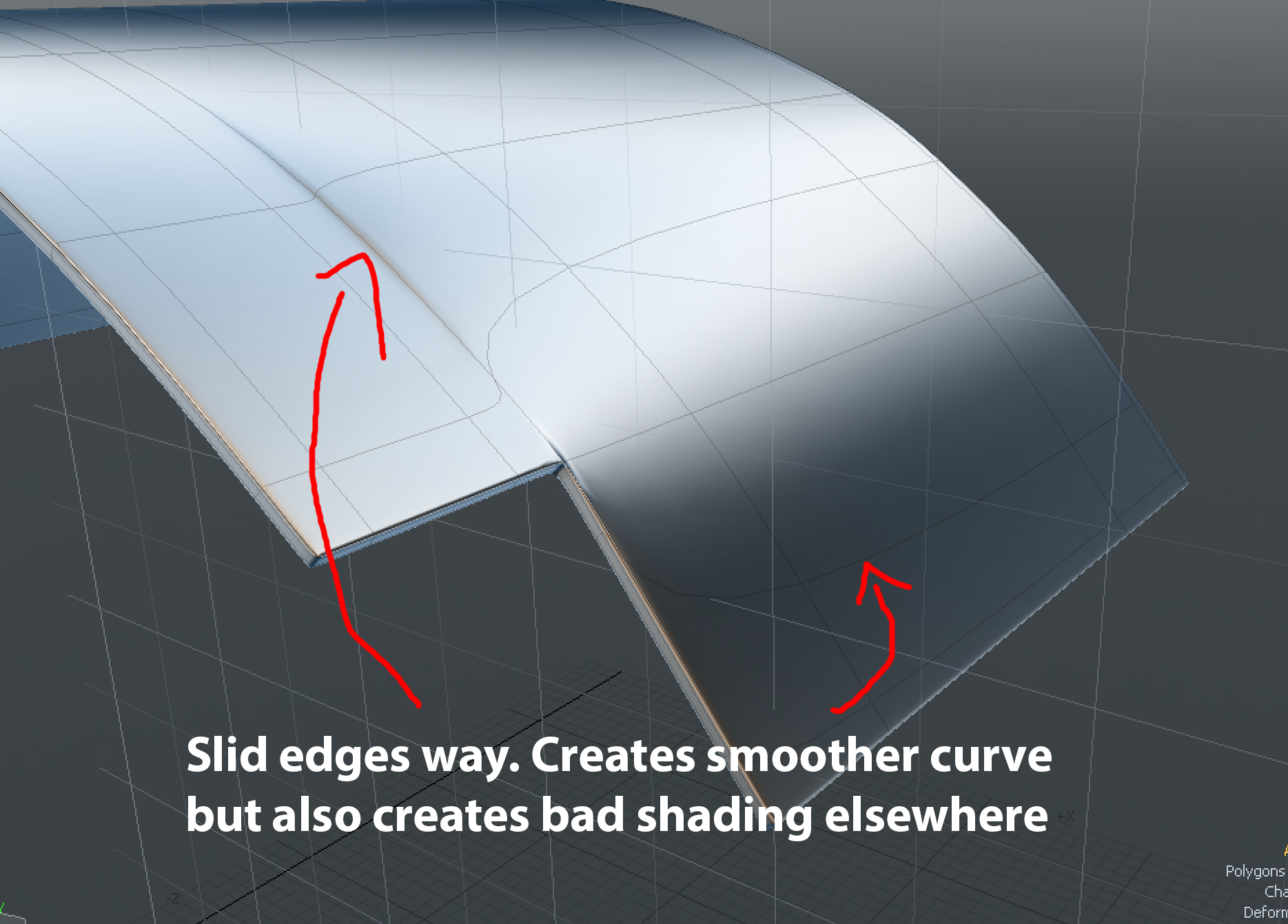

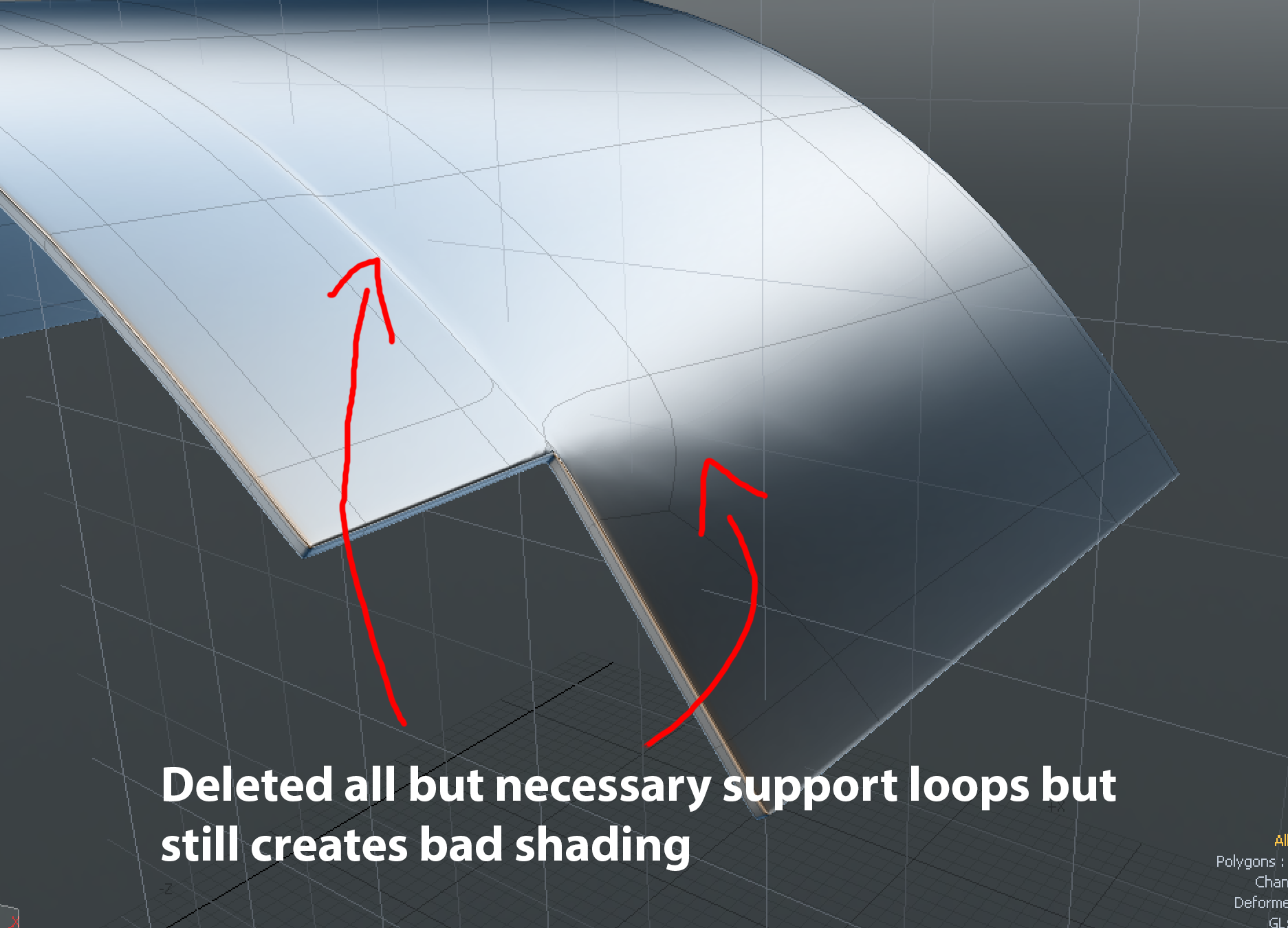

Basically I need to add some support loops for a very basic shape but it has this unusual cut-out section that messes with the curvature of other parts of the model when smoothed. Unfortunately it is one solid piece of folded metal and so I do not have the usual luxury of just seperating the elements out. I have tried a number of solutions such as sliding the supports loops around as well as removing them altogether. While this often softens my issue it also creates poor smoothing in other areas of the mesh. There are some pics below to try and illustrate my problem. Any advice on how to tackle this would be greatly appreciated. Thanks very much.

Rob

Hoping someone here can help me with a problem I seem to come accross quite a lot and have yet to find an elegant solution to. Apologies if this post is wordy as I find trying to describe this problem a little tricky.

Basically I need to add some support loops for a very basic shape but it has this unusual cut-out section that messes with the curvature of other parts of the model when smoothed. Unfortunately it is one solid piece of folded metal and so I do not have the usual luxury of just seperating the elements out. I have tried a number of solutions such as sliding the supports loops around as well as removing them altogether. While this often softens my issue it also creates poor smoothing in other areas of the mesh. There are some pics below to try and illustrate my problem. Any advice on how to tackle this would be greatly appreciated. Thanks very much.

Rob

Replies

Also, check out this thread http://polycount.com/discussion/56014/faq-how-u-model-dem-shapes-subd-mini-tuts-aka-use-the-right-amount-of-geo#latest

There's a lot of good info in there about how to manage problems like this.

Rob

Basically when subdivision occurs, on round/cylindrical objects, your polygons need to be evenly distributed - or at least reasonably so. When you put those two edge loops through your curved shape, your curvature is no longer evenly distributed - so it will cause pinching.

There's ways around this, with the simplest being to just start with a higher amount of geometry. A lot of the time people will also model cylindrical objects as a flat plane, then subdivide them once or twice, and then bend them 360 degrees - the bend prevents smoothing errors because it's perfectly bent.

In 3DS Max, you can also use the Turbosmooth modifier with "Smoothing groups" checked, which subdivides without the subdivision trying to smooth the object, so you get more topology to work with but no smoothing errors. After that, you can subdivide/turbosmooth again normally (this is called a double Turbosmooth, which you may have heard people say before :P)

The hard surface thread that DROSS3D inked is awesome for giving and obtaining help! One of my favourite Polycount threads.