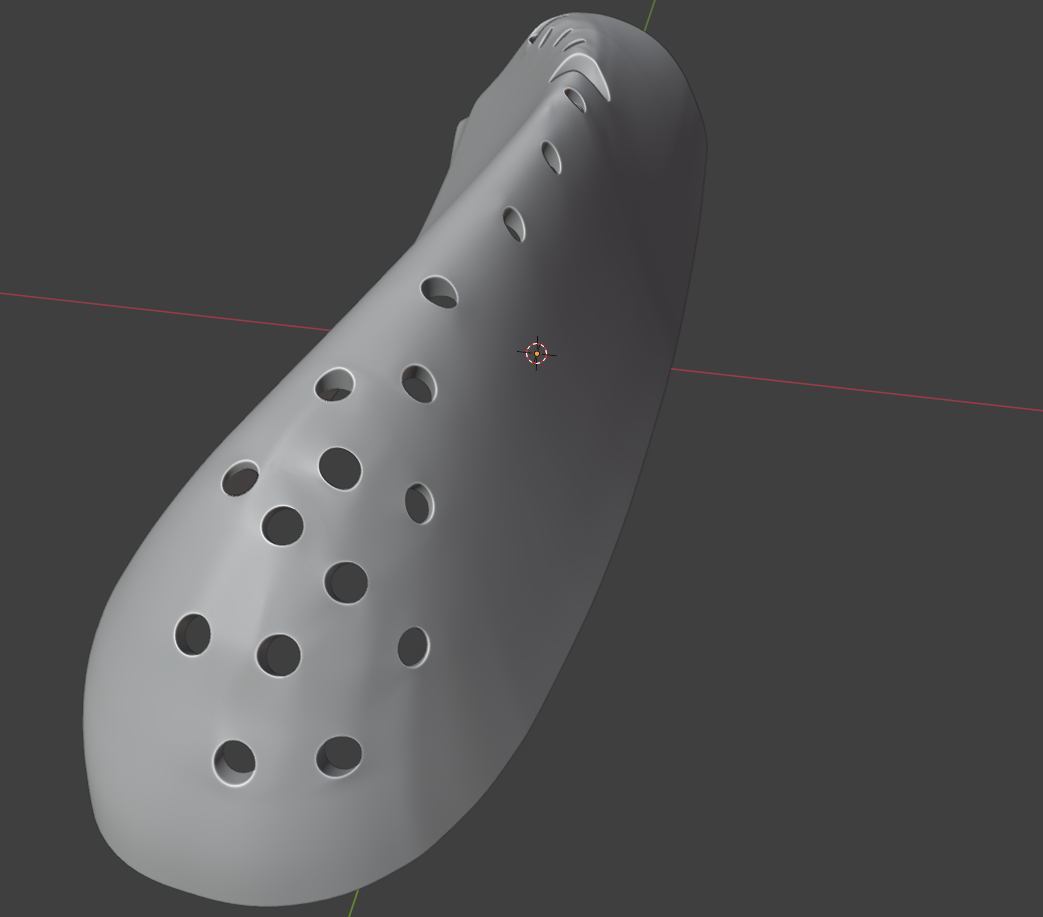

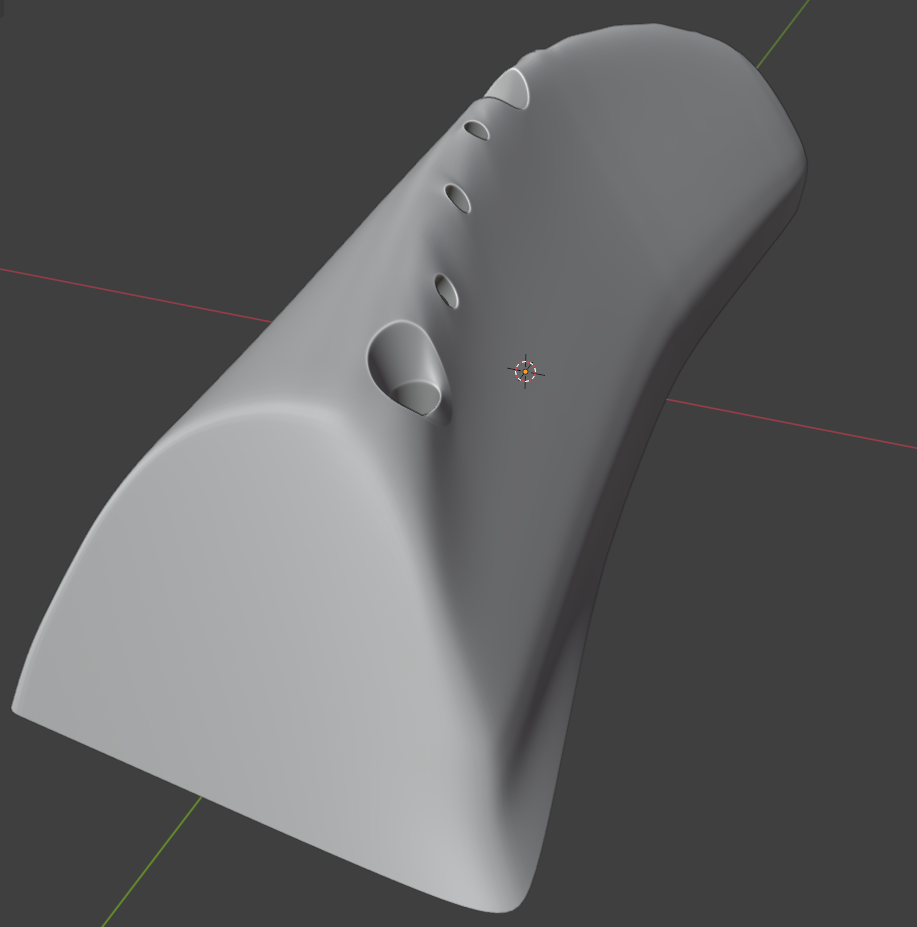

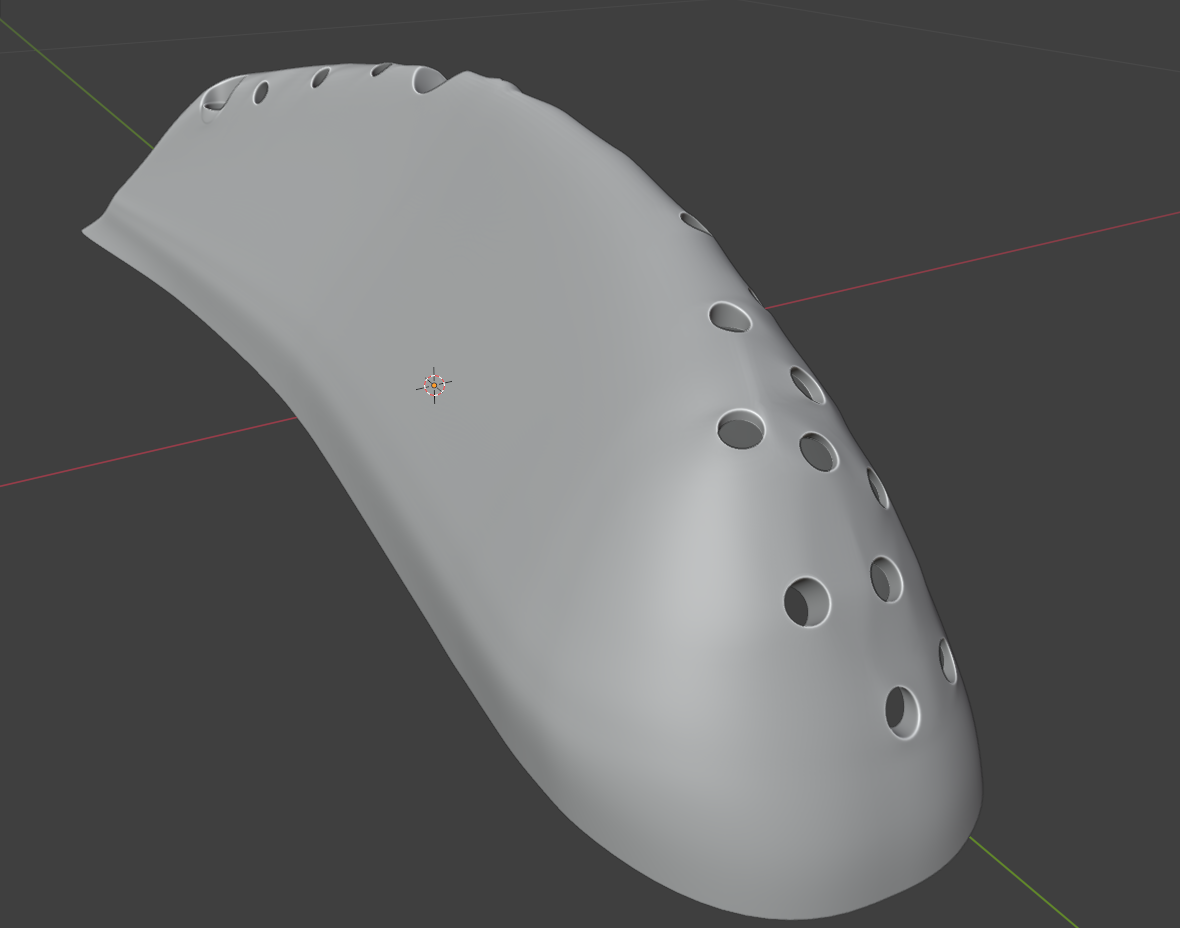

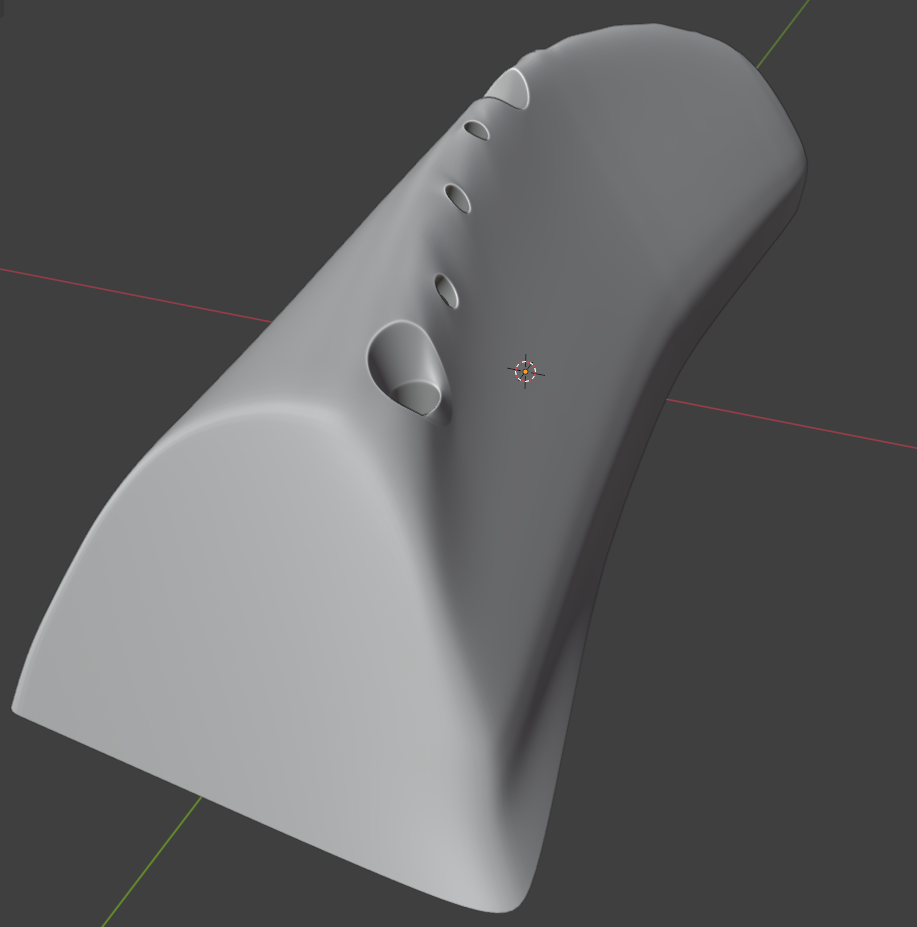

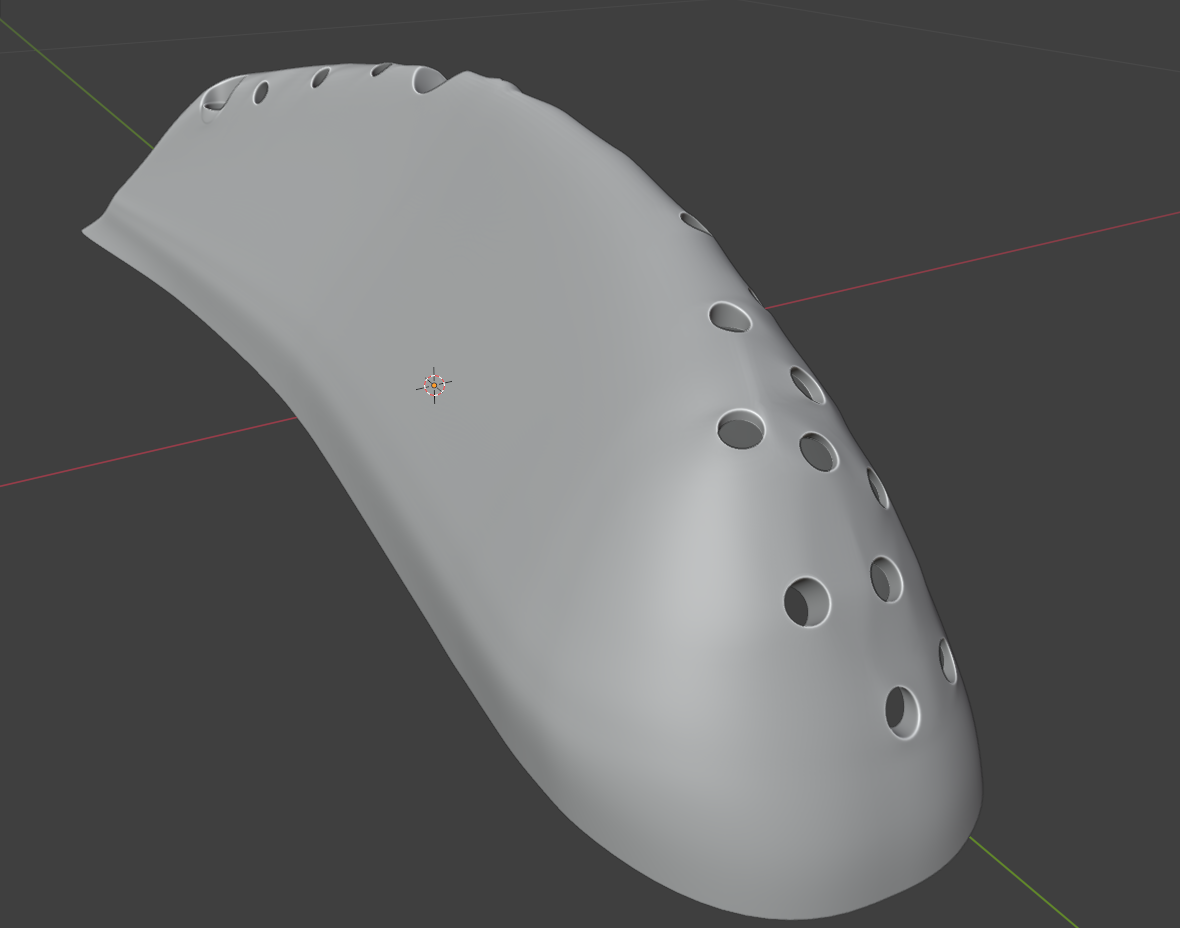

Washing Machine Part

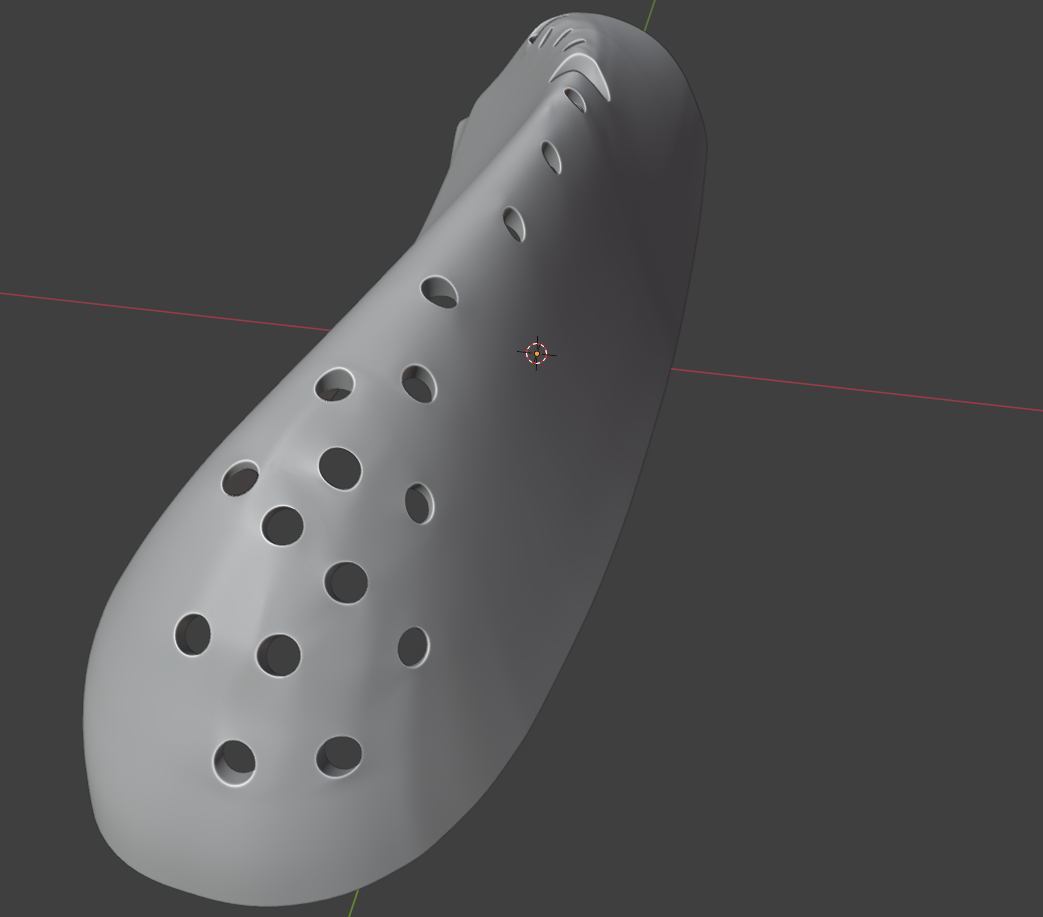

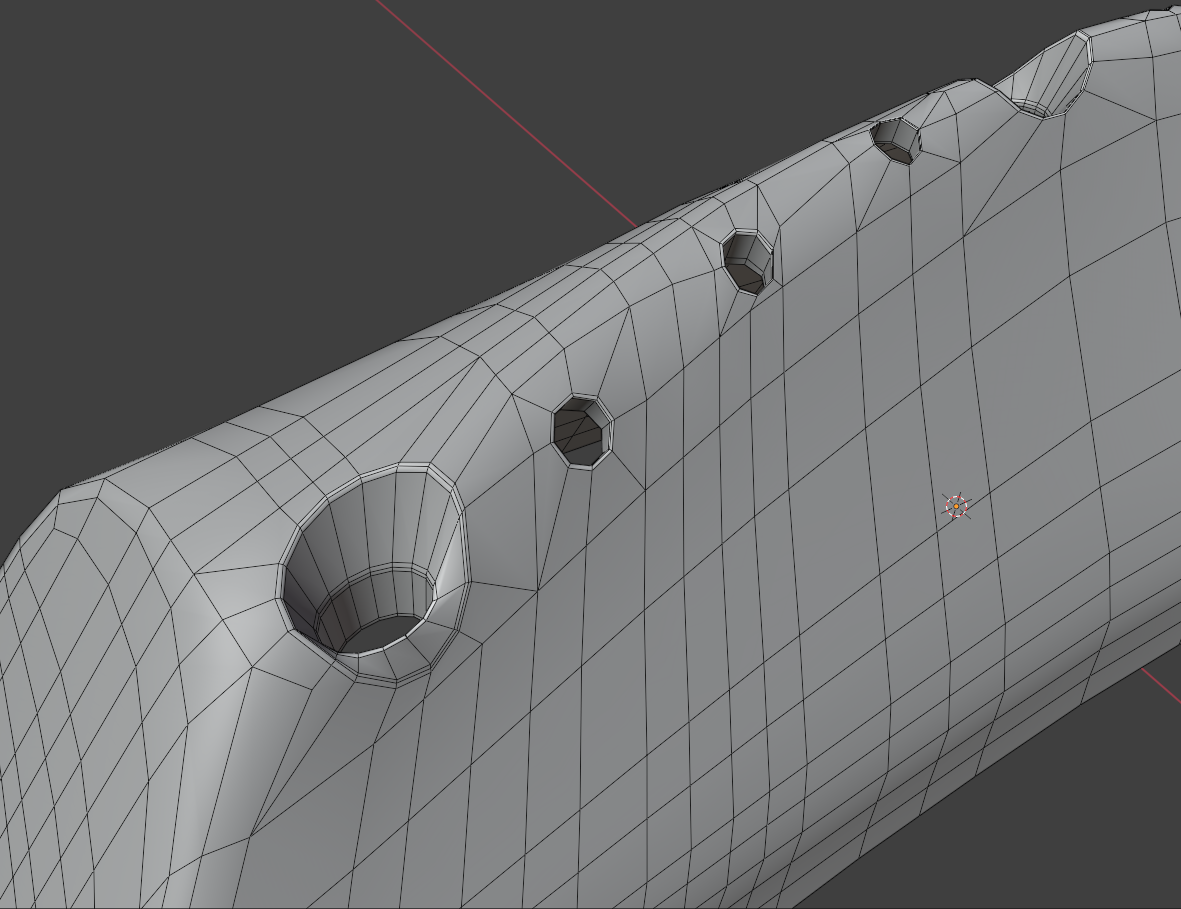

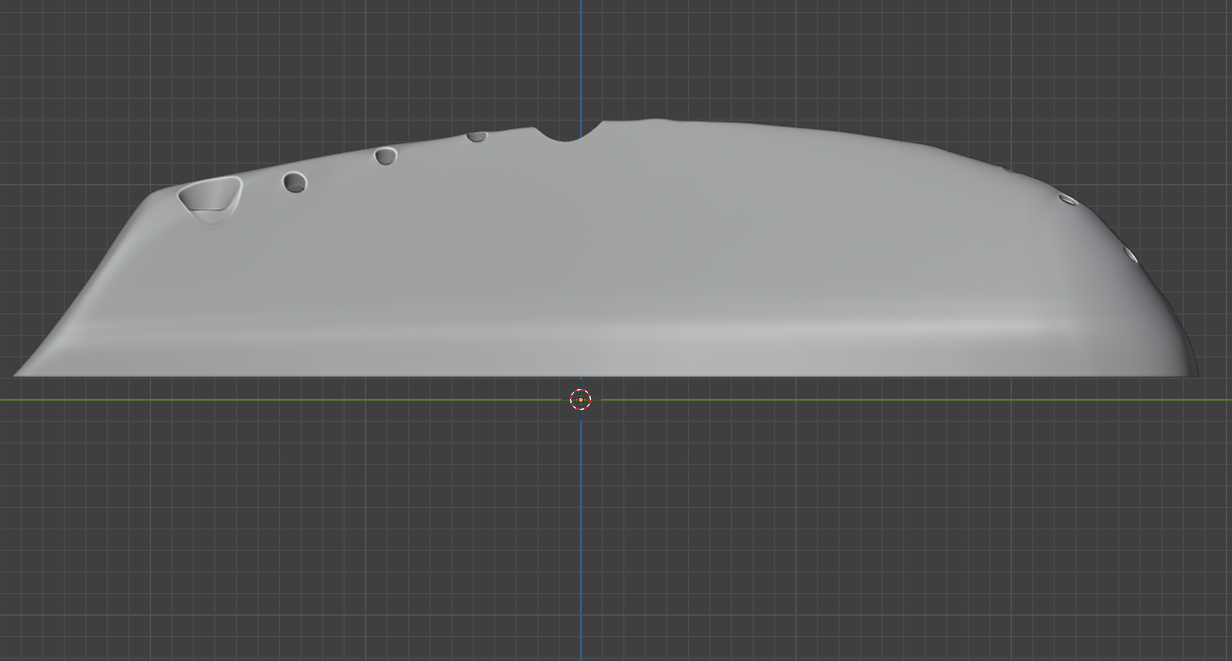

In an attempt to get better at Sub D and curved shapes I've been working on this washing machine part for a while and finally calling it done. It's done purely as a modelling exercise so it won't be baked or textured. It's my first time making a challenging shape like this so wanted to hear what you guys have to say. I'd like to get some feedback on these 3 factors:

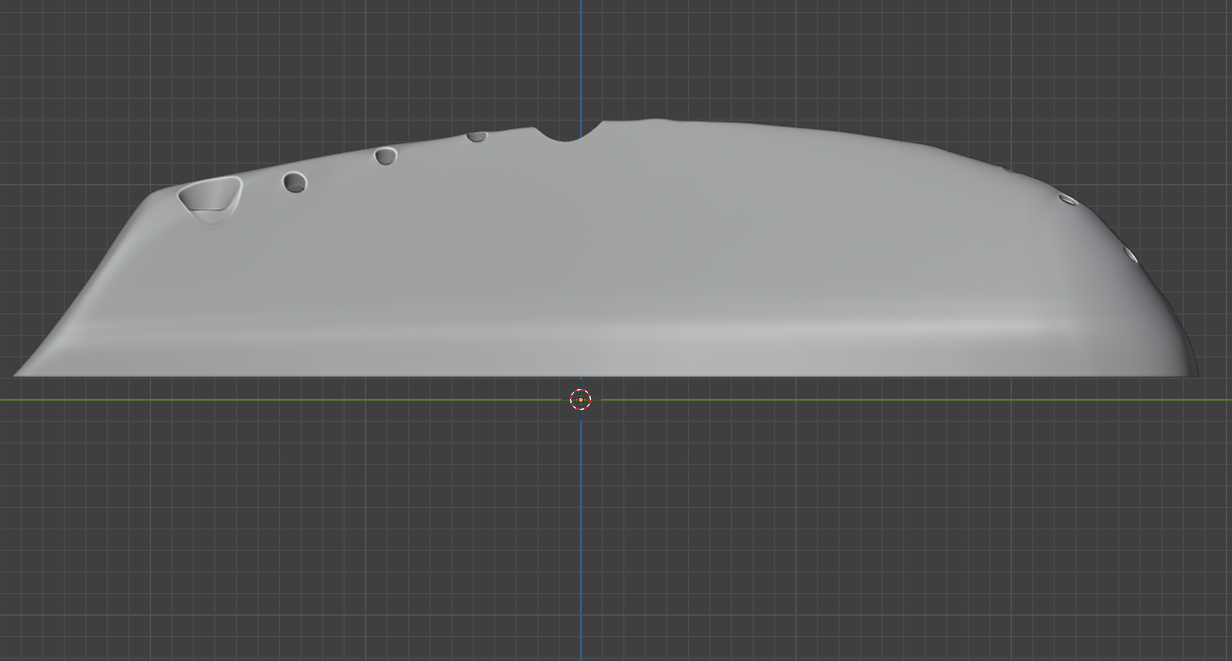

1.) How accurate is it to the reference?

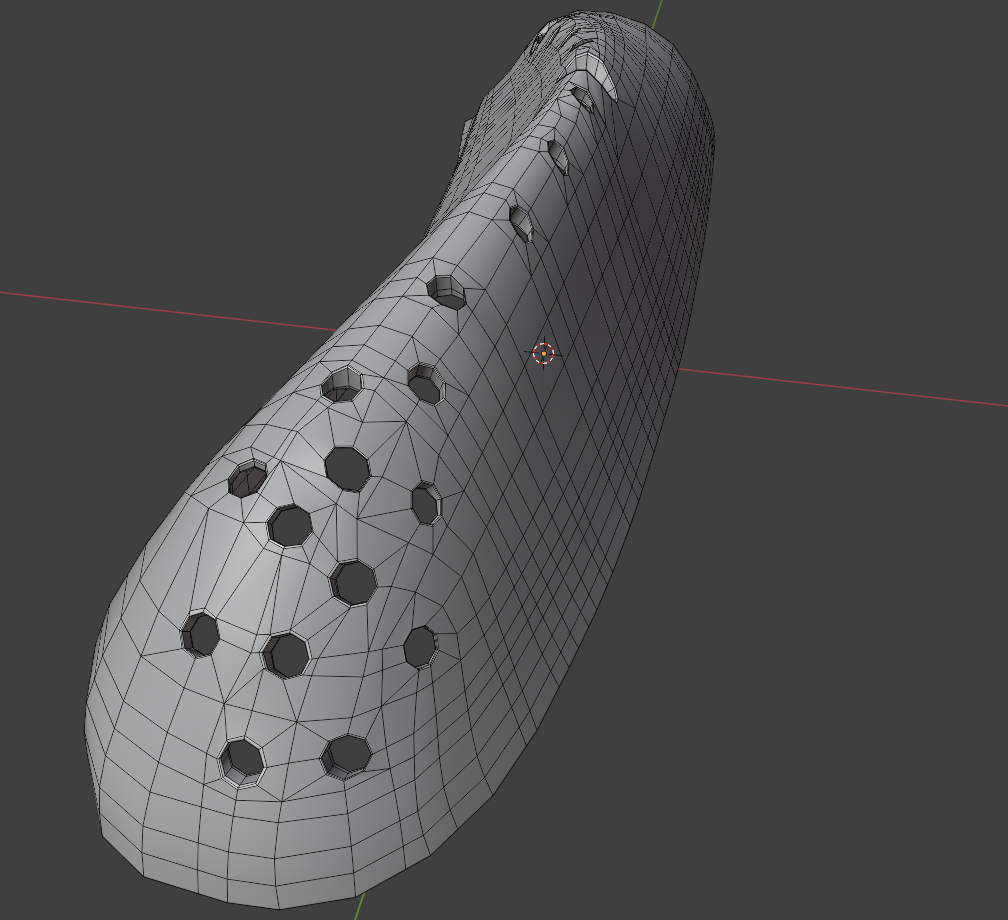

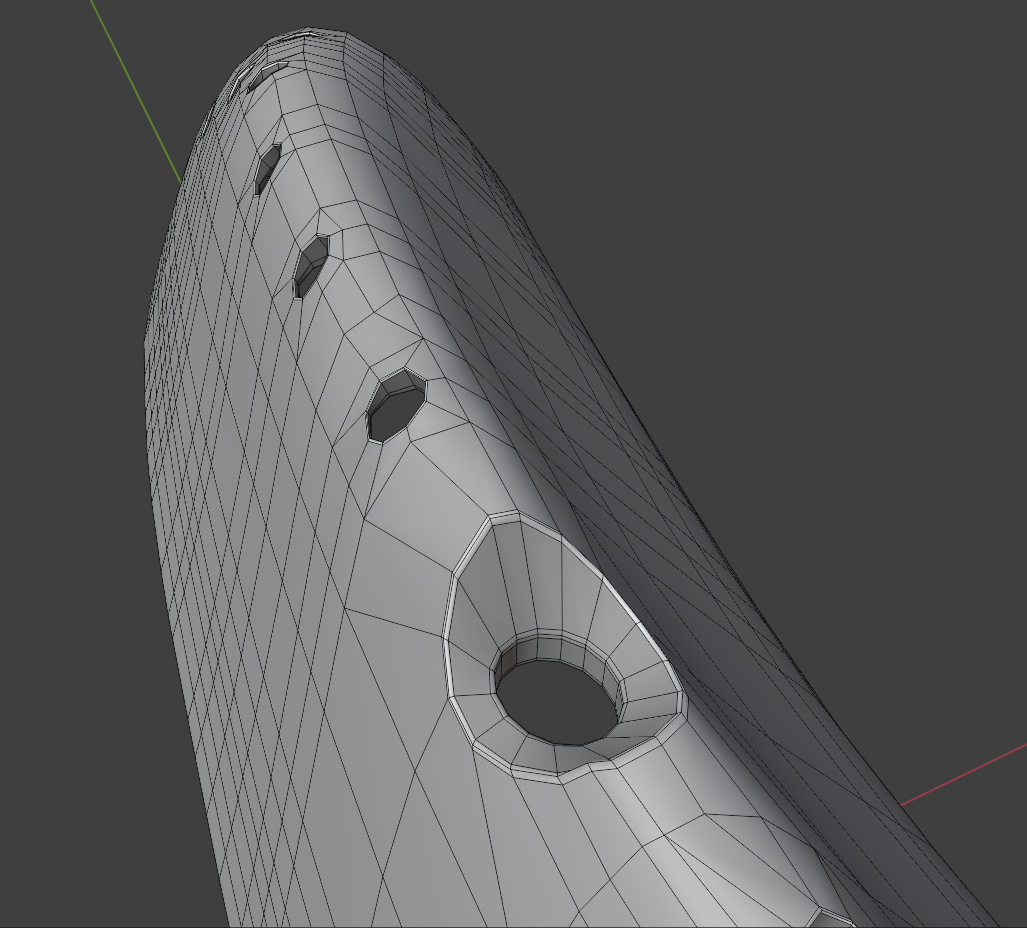

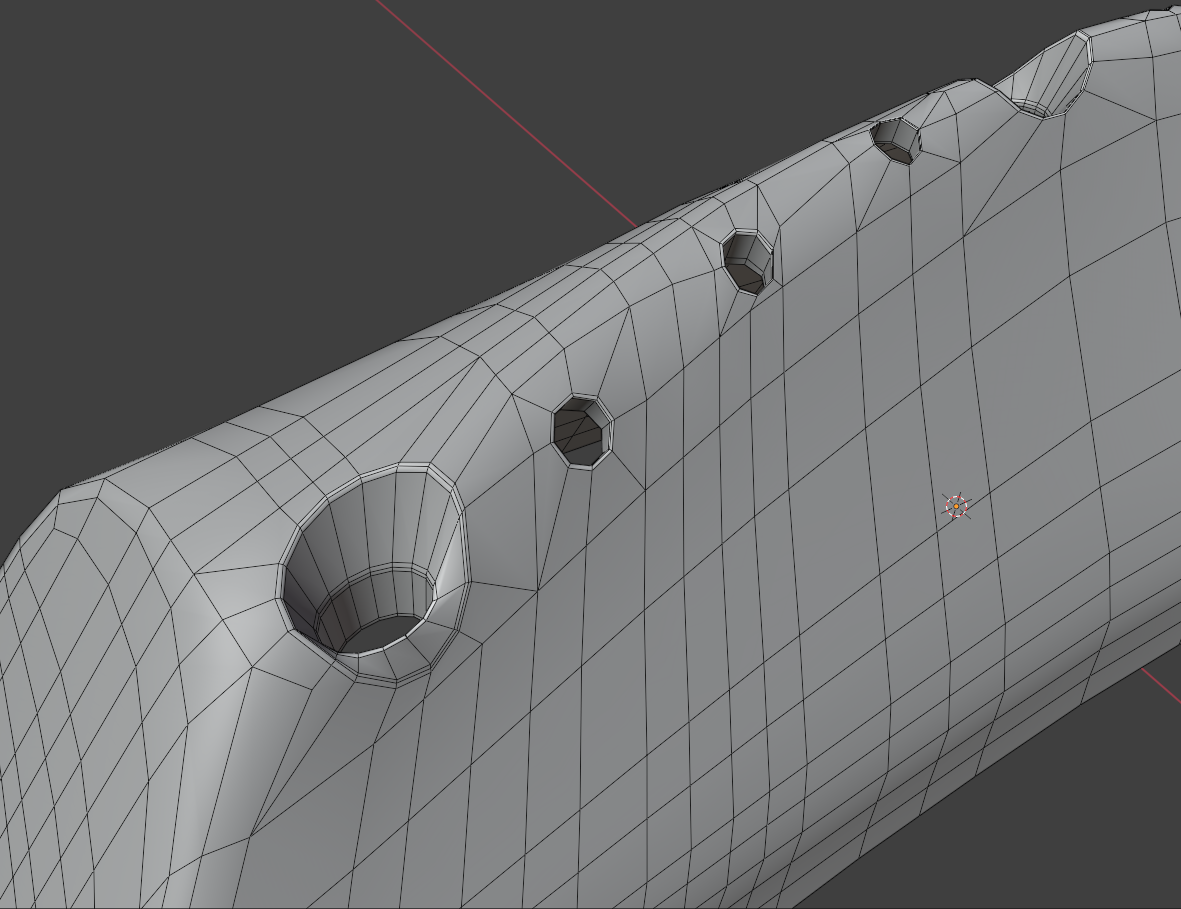

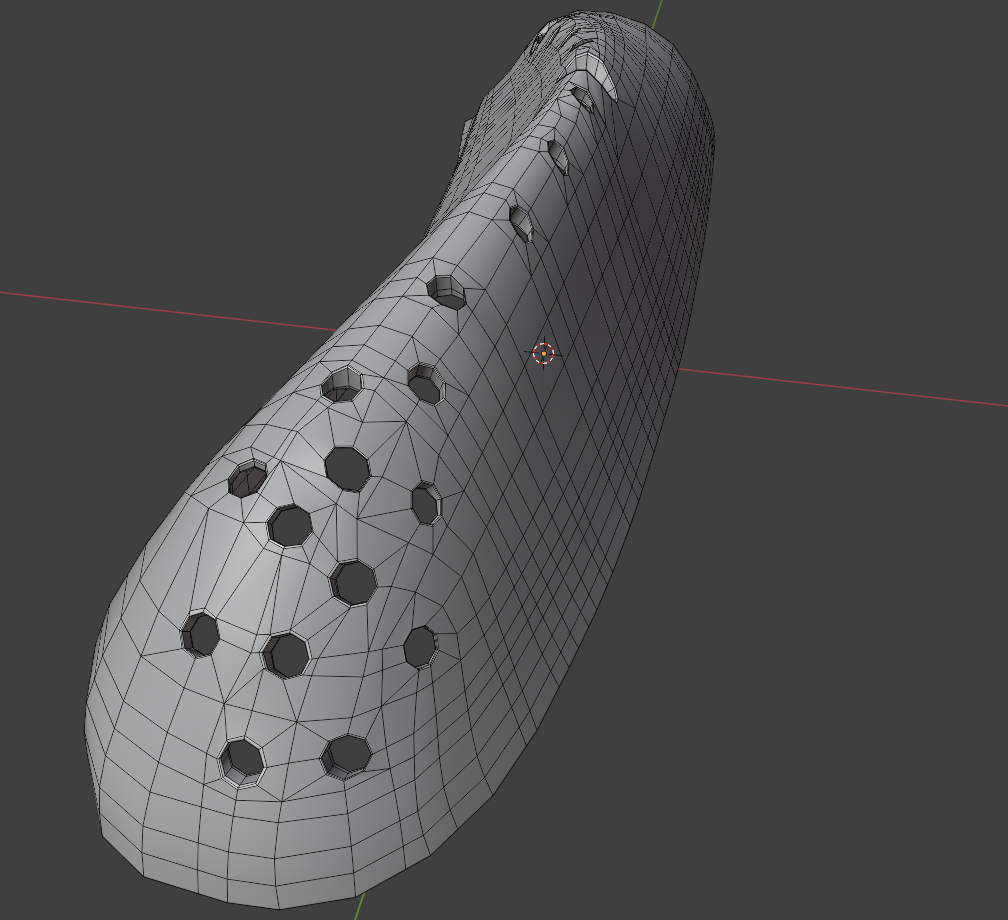

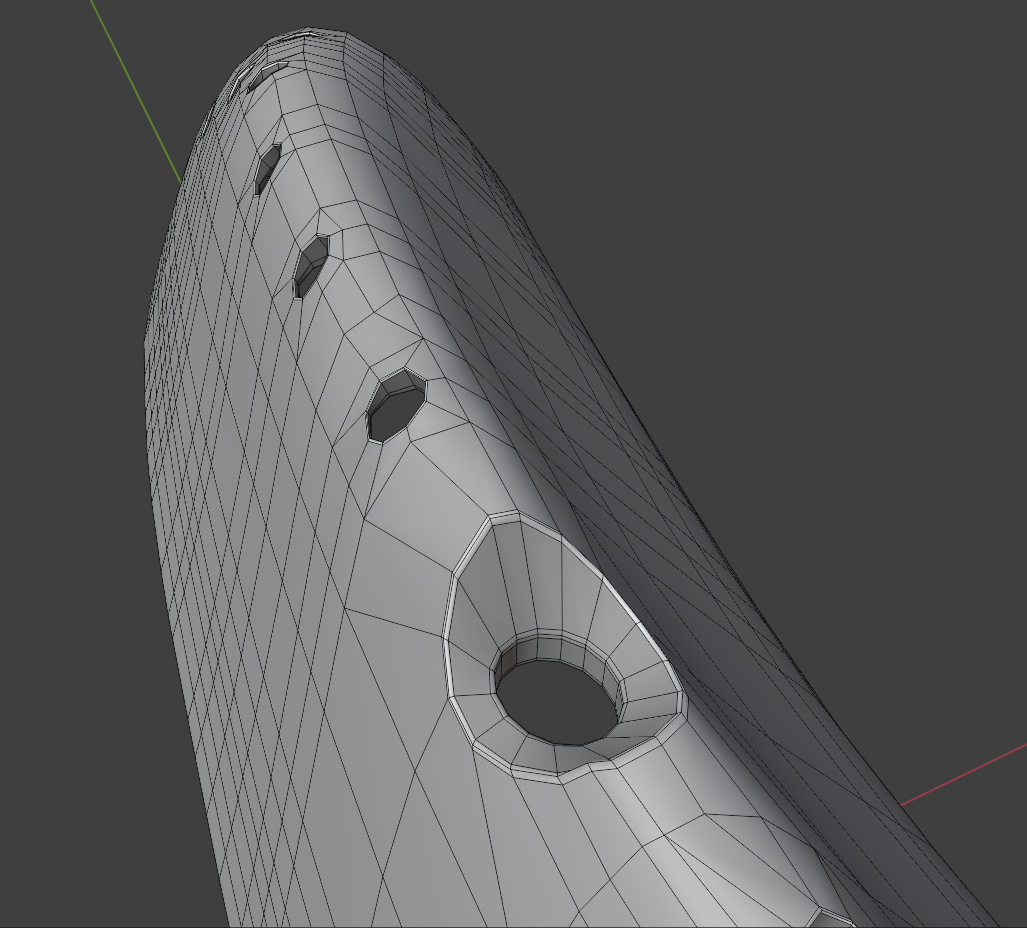

2.) Is the edge flow good or bad?

3.) Am I using polygons effectively?

1.) How accurate is it to the reference?

2.) Is the edge flow good or bad?

3.) Am I using polygons effectively?

Replies

1 - model out the major shape without holes in it, as a sub-d cage. <32 vertices should suffice.

2 - model out cylinders for the holes.

8 - boolean the subdivided meshes, possibly with a chamfer along the boolean seam.

Mesh feedback: Manually massaging a bunch of vertices to make a smooth sub-d mesh work should never happen. It leads to shading and topology issues as well as requiring a massive amount of time to do.