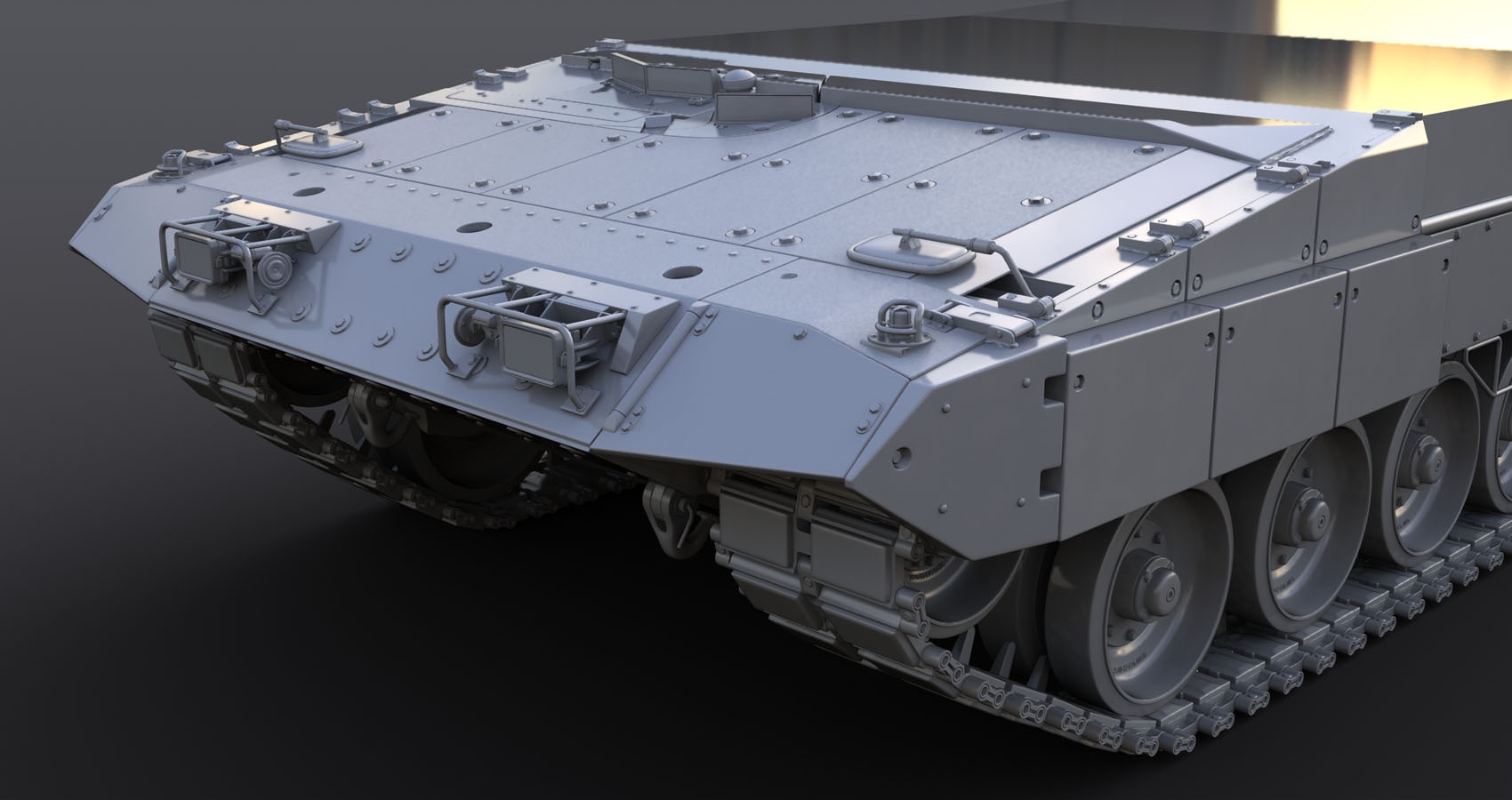

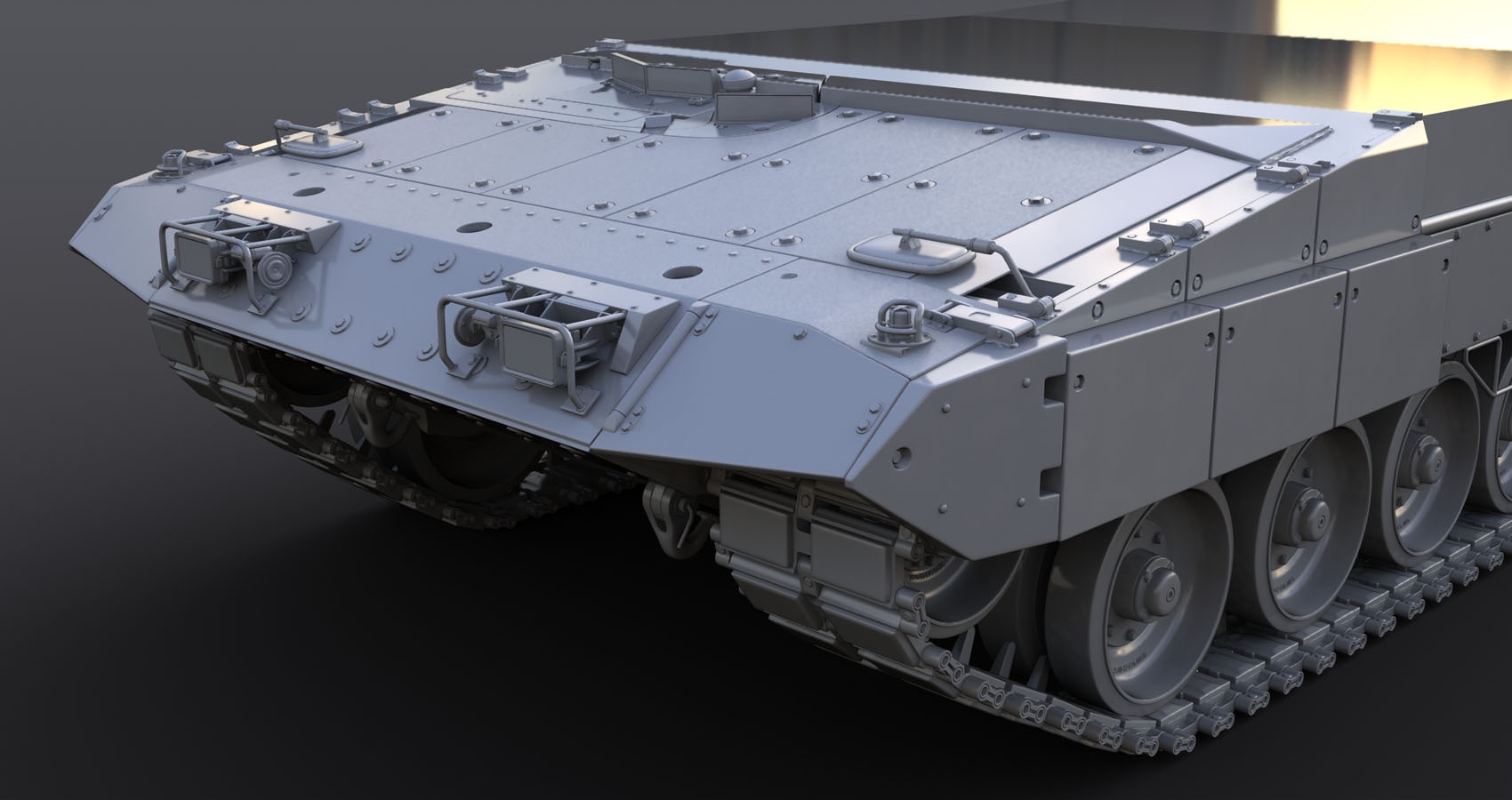

[WIP] Leopard 2 MBT A5 to A7+

Afternoon All

Been working on the latest project for a while now, but wanted to get to a certain point of development of the High Poly before i posted up.

Plan is to do a full High Poly and Low poly model of the Leopard 2 main battle tank, but to actually model all the versions including the A5, A6, A7 and A7+ (Urban Ops) and possibly the Swedish Variant STV122. I may even consider doing the A4 variant but there may be quite a bit of tweaking of the base mesh to make it realistic.

High Poly running gear and tracks 100% done and the front hull section for all versions 95% done so far.

All C & C welcome, but please note, the main hull itself is not yet Sub-D'd as i am waiting until all Hull details are modelled before i start adding edge support loops in etc

Whisky

Been working on the latest project for a while now, but wanted to get to a certain point of development of the High Poly before i posted up.

Plan is to do a full High Poly and Low poly model of the Leopard 2 main battle tank, but to actually model all the versions including the A5, A6, A7 and A7+ (Urban Ops) and possibly the Swedish Variant STV122. I may even consider doing the A4 variant but there may be quite a bit of tweaking of the base mesh to make it realistic.

High Poly running gear and tracks 100% done and the front hull section for all versions 95% done so far.

All C & C welcome, but please note, the main hull itself is not yet Sub-D'd as i am waiting until all Hull details are modelled before i start adding edge support loops in etc

Whisky

Replies

Been a while, but i have been working on the Leopard 2 in the margins. I am still working on modelling all the components of the Leopard 2 series from the A4 up to the A7+ and the hull is nearly done in this regards, just the A7 APU to finish on the rear of the hull and then the A4 drivers hatch which is completely different to any subsequent versions. There are many components which change through the iterations of the tank but for the ease of presenting the update, i am just showing the A7+ version.

For me It's always nice to see hardsurface modelling at this skill level.

The degree of precision is certainly impressive, down too the welds and what look to be indented road wheel part numbers. Would be interested for my own reference if you don't mind, how those details were created?

Anyway will definitely keep an eye out for updates, so subscribed

P.S.

As an aside, back in the day I'd initially signed up during my military service to work with a much earlier version (Leopard 1 A2) and from memory the only recognisable component on your model are the tracks. Teutonic engineering being what it is gave a sweet ride barrelling across country at 80kms+, although a back breaking affair servicing them

So your two questions, how i create welds and part numbers on the wheels

Welds:

1- I create an editable spline manually or use the "Create Shape from Selection> Linear" in the Editable poly modifier which is basically the shape of how i want the weld seam to run along the model.

2- I then turn on render in viewport and set the diameter of the "tube" to be the width/ size i want the weld to be. You can always use a push modifier later if you want to fine tune.

3 - Convert to an editable poly or add a Edit Poly modifier (i dont like keeping stacks in Max

3 - I then add supporting edge loops along edges, ready for the turbosmooth modifier i then add. This is only to a more geometry onto the tube ready for the next noise modifier.

4 - Add a noise modifier, turn on "Fractal" and i always just crank up the "Roughness" to 1.0 and "Iterations" 10.0

5 - Play with the strength values until i have something that looks about right. I generally make it slightly noisier than i actually want as i then add a second turbosmooth modifier onto the top of the stack just to smooth it out. I generally keep the X, Y and Z strengths the same.

6 - FIN

I have seem some people take models into ZBrush to create the welds, but for me this is overkill and this quicker solution delivers a 90% solution which much less faff.

Part Numbers:

So, what i did for these, similar to welds, is create editable splines/ lines to create the wording and letter i want. Make renderable, give a thickness i want, turn to a editable poly and add a turbo smooth modifier. For this i just spent 15 minutes one day creating the alphabet and numbers i wanted, which i then just copy and paste around to where i need/ want it. Obviously cant replicate complex fonts like this, but generally for cast or stamped lettering/ numbering, they are not complex fonts anyway.

Again, not a 100% solution, as you dont get a nice feathered edge from the base plate up to the writing, but i find this bakes out sufficiently good enough.

Hope this helps

@WhiskyDelta

Thankyou. I've something planned more so as a refresher exercise than anything else which hopefully I'll post on this forum shortly and these workflows you've kindly shared will certainly come in handy, again much appreciated.

Cheers.

Another quick update, the Hull/s are now pretty much complete for all versions of the Leopard, having now created all the variations i need for the A4 through to A7+ versions. To demonstrate the progress i will just show the A4 and A7+ configurations.

Leopard 2 A4

Leopard 2 A7+

All C&C welcome...

Regards

Whisky

All that remains is the loaders anti-air machine gun, of which i will have to create two, an FN Mag and a MG3.

Whisky

Very nice, everything looks so clean and precise that I've no crit's too offer.

Anyways great going man, thanks again for sharing.

Cheers.

I have been progressing on this project in the background, but the MG3 ended up being far more complex and detailed than i anticipated. Or rather, i ended up wanting to model a far more detailed and complex MG3 than i anticipated!

I am not making every last component "animateable", but i will create the MG3 so you can alternate between the normal flip up iron sights and the AA sights, in addition to working bipod and receiver cover. You can see the MG3 is in the two different configurations between the above two images.

Just the lower receiver, receiver cover and ammo box to go.

Whisky

Warning, quite a few high res images following!

I must say, Toolbag baking and Substance Painter texturing workflow is fantastic! Once i finished the A4, i brought in the A5 meshes into the same project and 80% of hand painted camo scheme re-projected perfectly. Only in areas where the A4 and A5 geometry was significant different (turret) did i have to do some tidy up . Textures wise, each Leopard has 4 texture sets, breakdown below:

1024 x 512 track texture

2048 x 2048 running gear texture

4096 x 4096 hull texture

2048 x 4096 (A4) turret/ 4096 x 4096 (A5) turret

Regards

Whisky

Wow! well done man and the texturing is especially mouth watering too.

Cheers.

EDIT:

Also just quietly a much needed inspiration to drag my project back from the dead.

Id definitely now put a couple more hours for some nice presentation, try put it on some mud ground and with a nice strong sun light, the current lighting feels a bit weak. You can get a small ground environment + skybox done in 10% of the time of the model, but the final artwork will be much more valuable in your portfolio.