The BRAWL² Tournament Challenge has been announced!

It starts May 12, and ends Oct 17. Let's see what you got!

https://polycount.com/discussion/237047/the-brawl²-tournament

It starts May 12, and ends Oct 17. Let's see what you got!

https://polycount.com/discussion/237047/the-brawl²-tournament

Rock "Crawler" :)

Rock "Crawler"

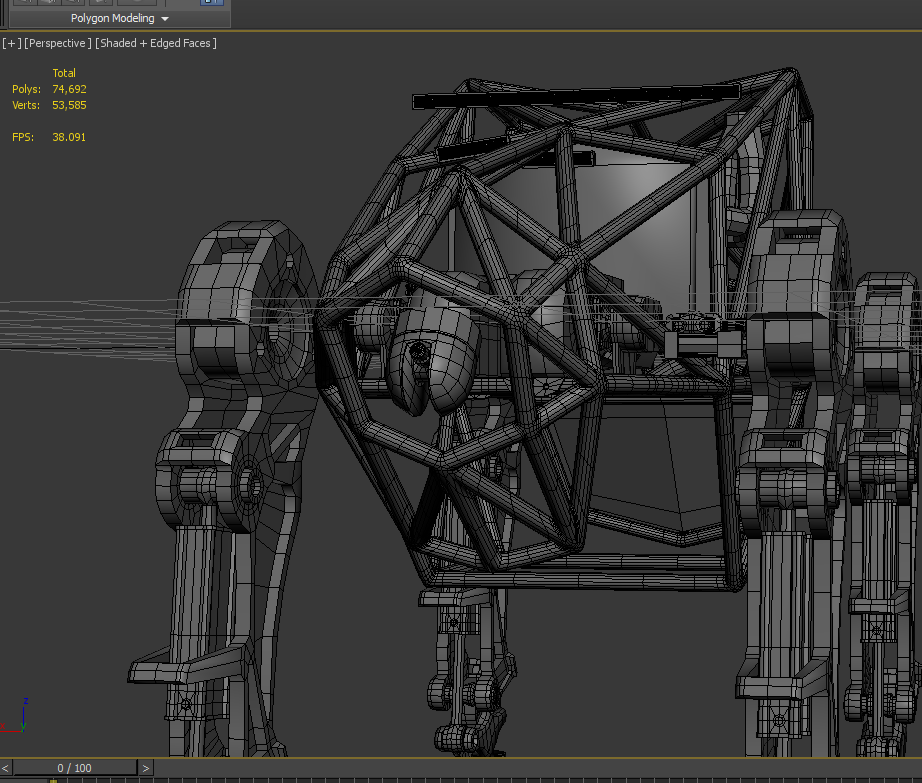

Loooong time lurker, first time project post, trying to get over that hump of being terrified and intimidated- I gotta post this if I'm going to get feedback and get better.

If gearhead talk bores you, scroll right past this text and look at the pictures

Here's a huge writeup fueled by coffee- if you like boring technical talk of mechanical stuff, indulge me! I HAVE A LOT OF COFFEE IN MY BELLY OH MY GOD

Ahem.

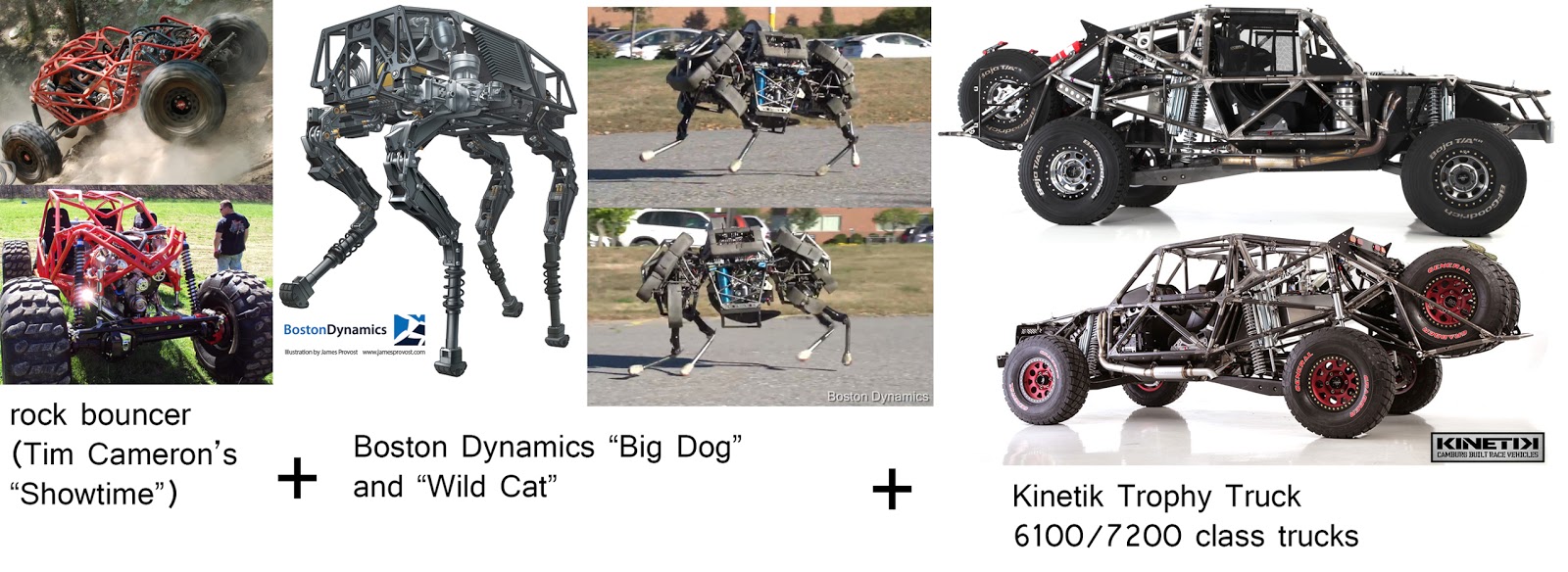

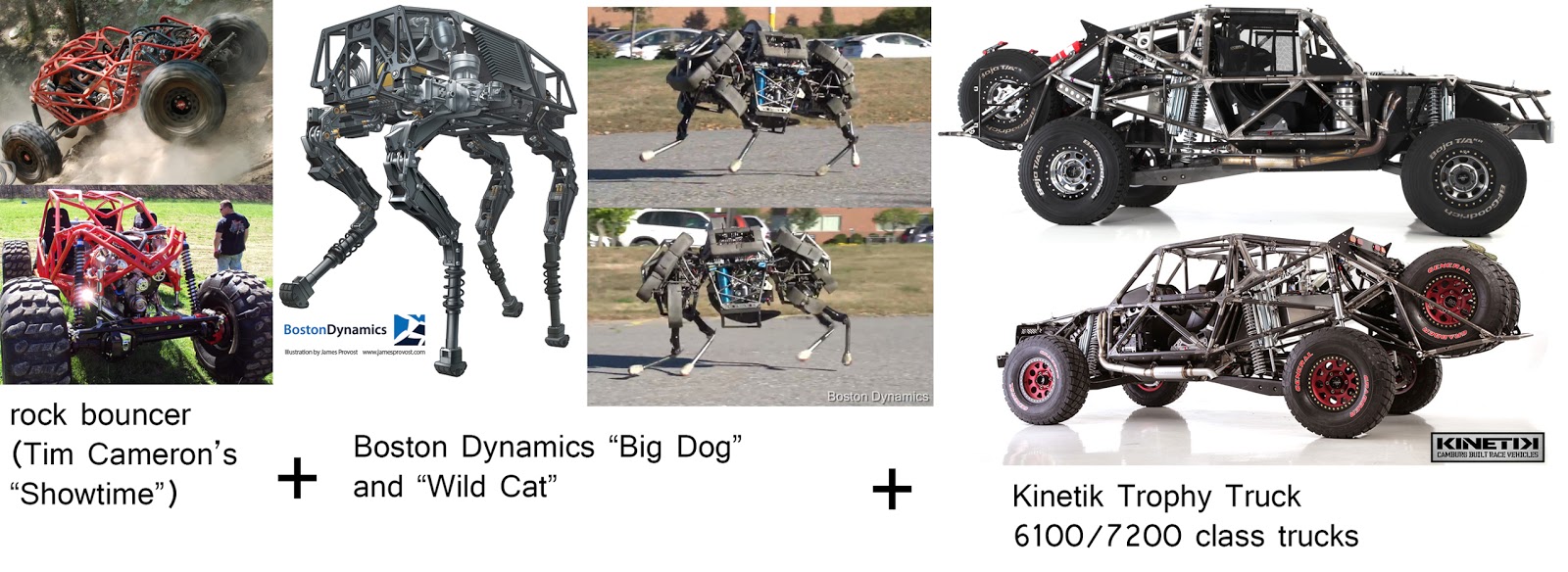

Seen here is the inspiration ingredient sheet:

"Rock Crawler" - representative sample, youtube video

[ame] https://www.youtube.com/watch?v=acalNRlT2I0[/ame]

https://www.youtube.com/watch?v=acalNRlT2I0[/ame]

The tubed-chassis 'buggy'- Rock crawlers typically remove as much sheet metal from the body as possible, for wheel travel, for less interference on obstacles (fenders and fender flares typically cut away, corners are 'comp cut', rocker panels are trimmed as high up on the sides as possible, etc). Crawlers are typically meant for methodical, slow paced driving over obstacles, i e rocks. Usually there are a lot of extra control measures- separate front/rear brakes for front and rear digs (spinning the front or rear wheels, burnout fashion will spin free the dirt or moss in the tread and then dry the tire for better traction- alternating front and rear with this action will maintain control- think of a rock climber chalking his hands), cutting brakes (think tractor brakes. two levers, one for each rear wheel, used to pivot on one of the rear wheels for steering rather than using the front wheels), hand throttle (sometimes a modified bmx brake lever mounted to the shifter- basically allows one hand on the steering wheel, one hand on the shifter controlling shifting and throttle input, and one foot on the clutch and one foot on the brakes) . Very technical rigs, great engineering resource. For mechanical reference, I suggest you check out the Pirate4x4 forums, such as the Jeep forum, as an example: http://www.pirate4x4.com/forum/jeep-hardcore-tech/804177-heavily-mogified.html

http://www.pirate4x4.com/forum/jeep-hardcore-tech/882928-project-dookeys-revenge.html

"Rock Bouncer" - representative sample, youtube video

[ame] https://www.youtube.com/watch?v=4A98SJg-iuc[/ame]

https://www.youtube.com/watch?v=4A98SJg-iuc[/ame]

Rock Bouncers are sort of a sub culture of rock crawling, typically regarded as the more 'daredevil' crowd. You'll see more instances of LPG powered engines- a gas engine that's carbeurated will have trouble in off-camber or deeply tilted angles, remedied by running electronic fuel injection, but that still has its limits- so these guys will run propane-powered rigs a lot. Idea being, this will run the same when upside down. Rock Bouncers are typically automatic transmission (go pedal, stop pedal) for simplicity, typically don't have a winch ( recovery is just a matter of gunning the gas and flipping back over ) No finesse, all raw adrenaline/testosterone/horsepower. Pure badassery, great ingredient in the 'project soup'

) No finesse, all raw adrenaline/testosterone/horsepower. Pure badassery, great ingredient in the 'project soup'

"Big Dog" - schematics pdf, technical documentation, representative video

video- [ame] https://www.youtube.com/watch?v=W1czBcnX1Ww[/ame]

https://www.youtube.com/watch?v=W1czBcnX1Ww[/ame]

pdf: http://www.bostondynamics.com/img/BigDog_IFAC_Apr-8-2008.pdf

http://www.bostondynamics.com/img/BigDog_Overview.pdf

http://www.bostondynamics.com/robot_bigdog.html

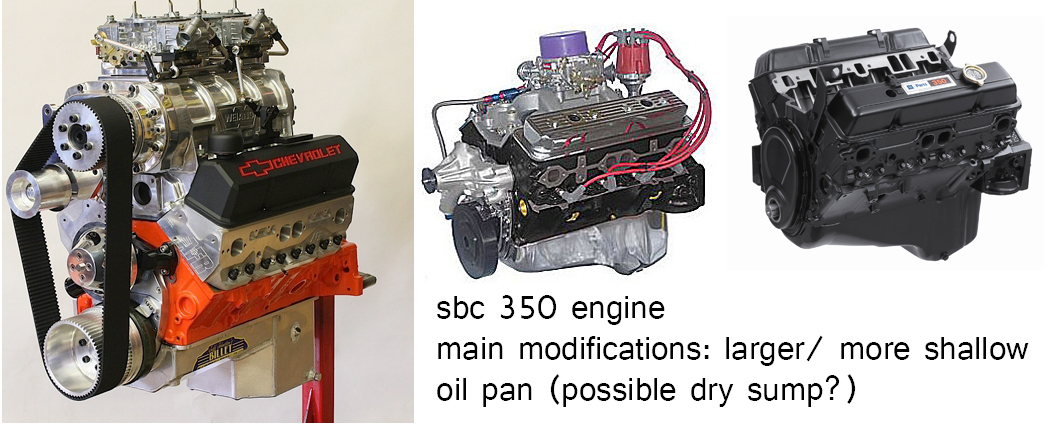

15 horsepower go-kart engine

Engine:

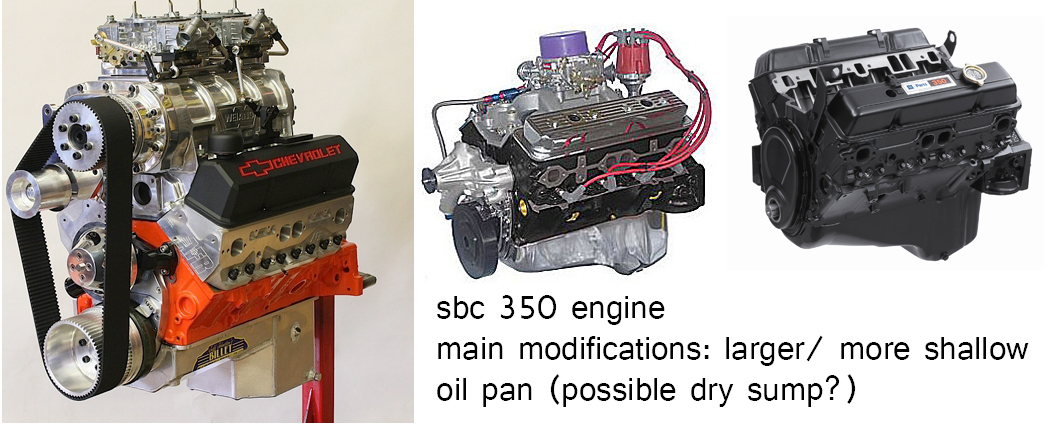

since this is a scaled up version of the Big Dog/ Wildcat, I'll be using a 'small block chevy 350 cubic inch' naturally aspirated v8 engine. On the low end, a crate engine will produce around ~200 horsepower with a pretty flat torque curve, but since in this usage it's mainly for a direct RPM - to - PTO for the hydraulic pumps and the alternator to power the electronics, it's all about a fast revving torque-y engine. The video below should give an idea of how I imagine the 'crawler' will sound, big contrast from the whiny mosquito engine from the video above:

[ame] https://www.youtube.com/watch?v=hyPQzPKIqsk&list=FLRo0FvL9EPL6UWq2mLX-Rhg&index=48[/ame]

https://www.youtube.com/watch?v=hyPQzPKIqsk&list=FLRo0FvL9EPL6UWq2mLX-Rhg&index=48[/ame]

Ambulatory modules:

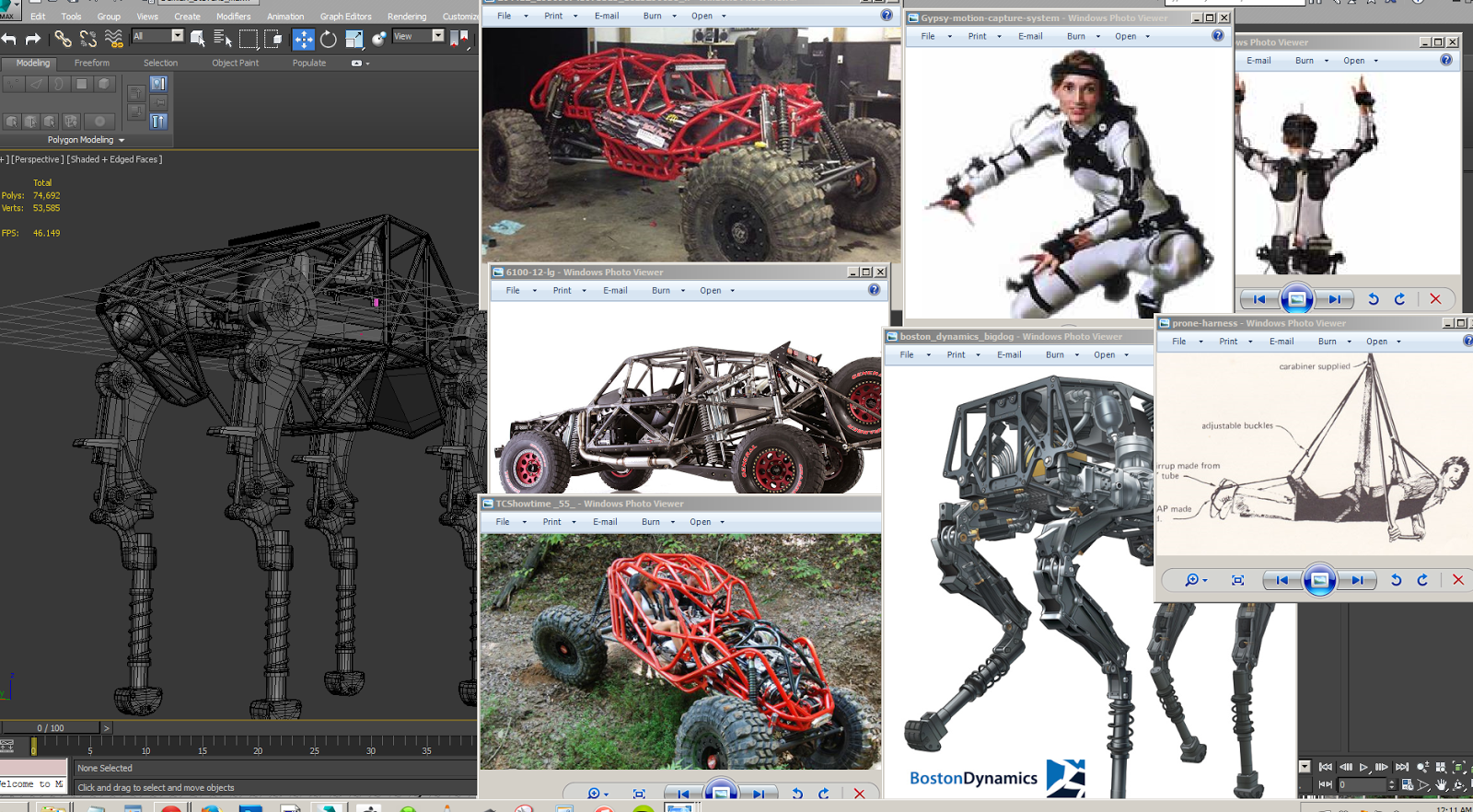

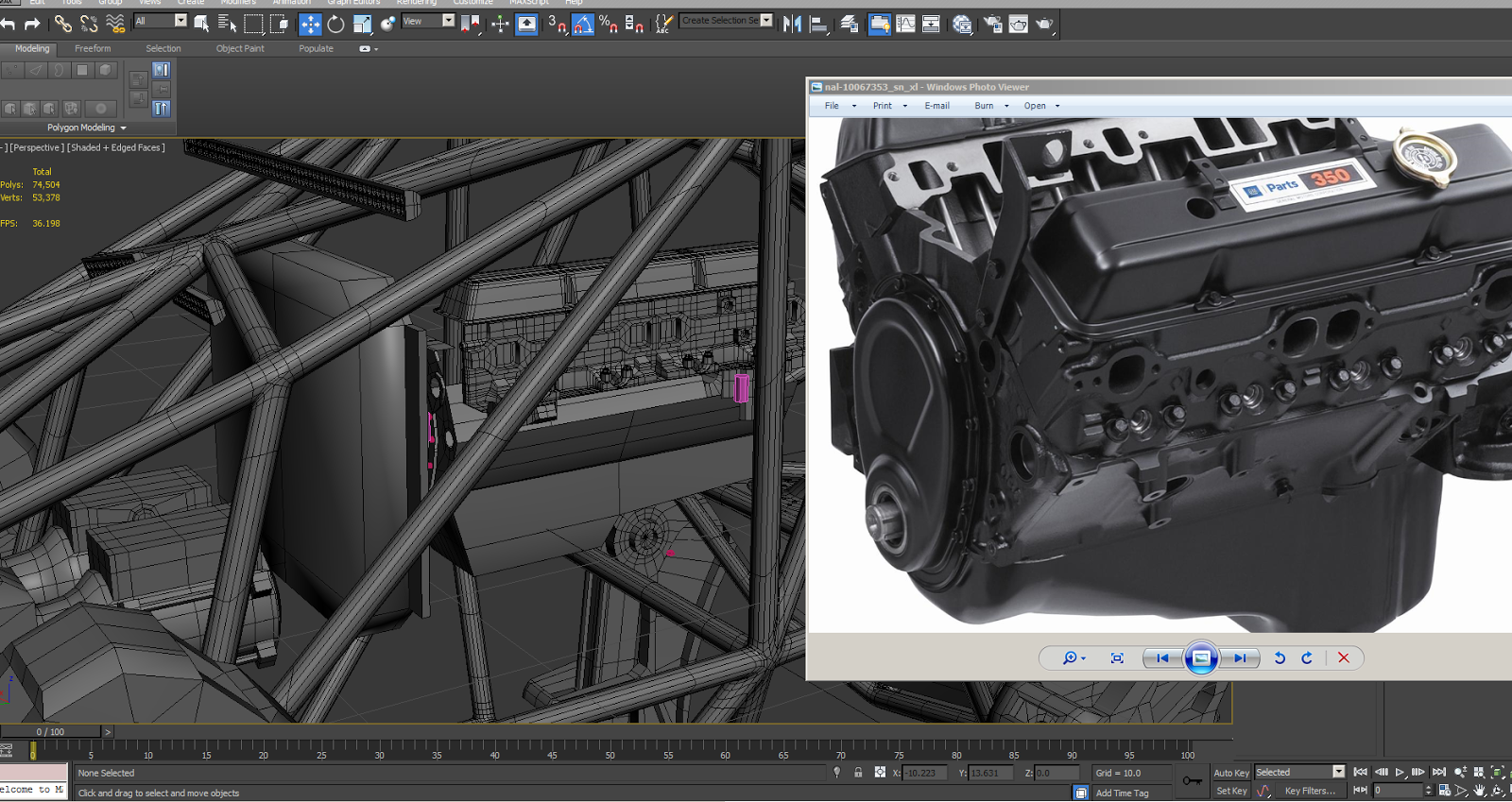

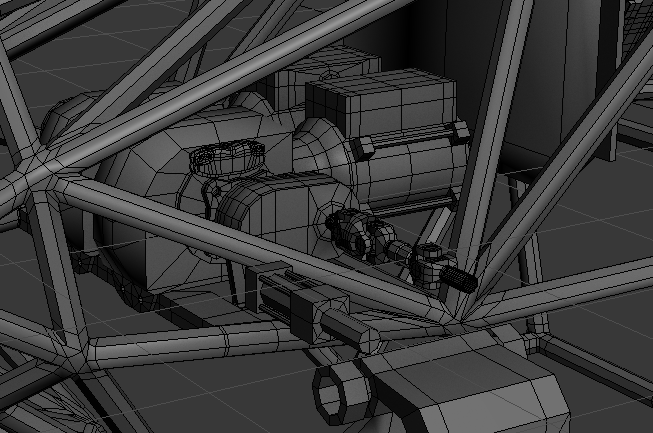

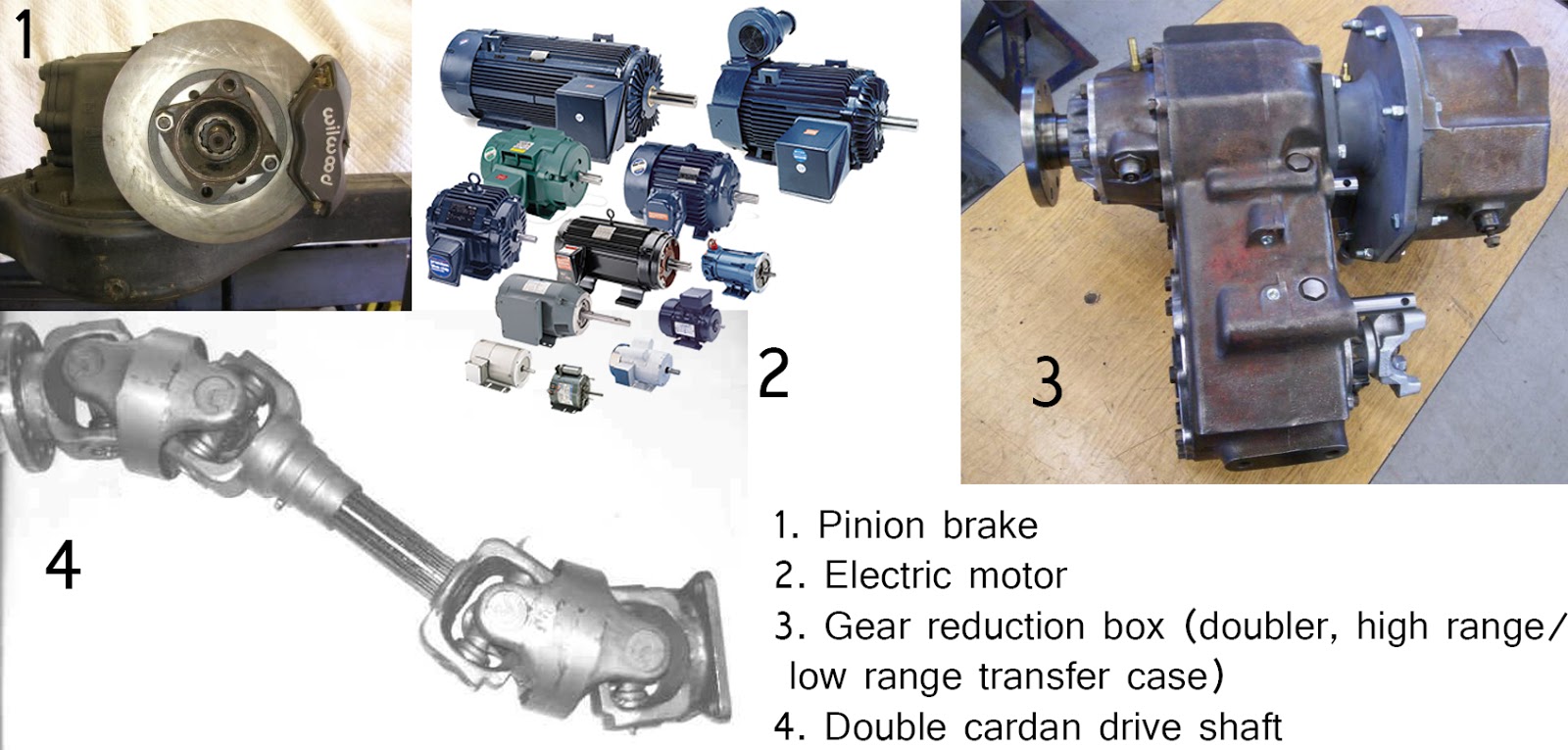

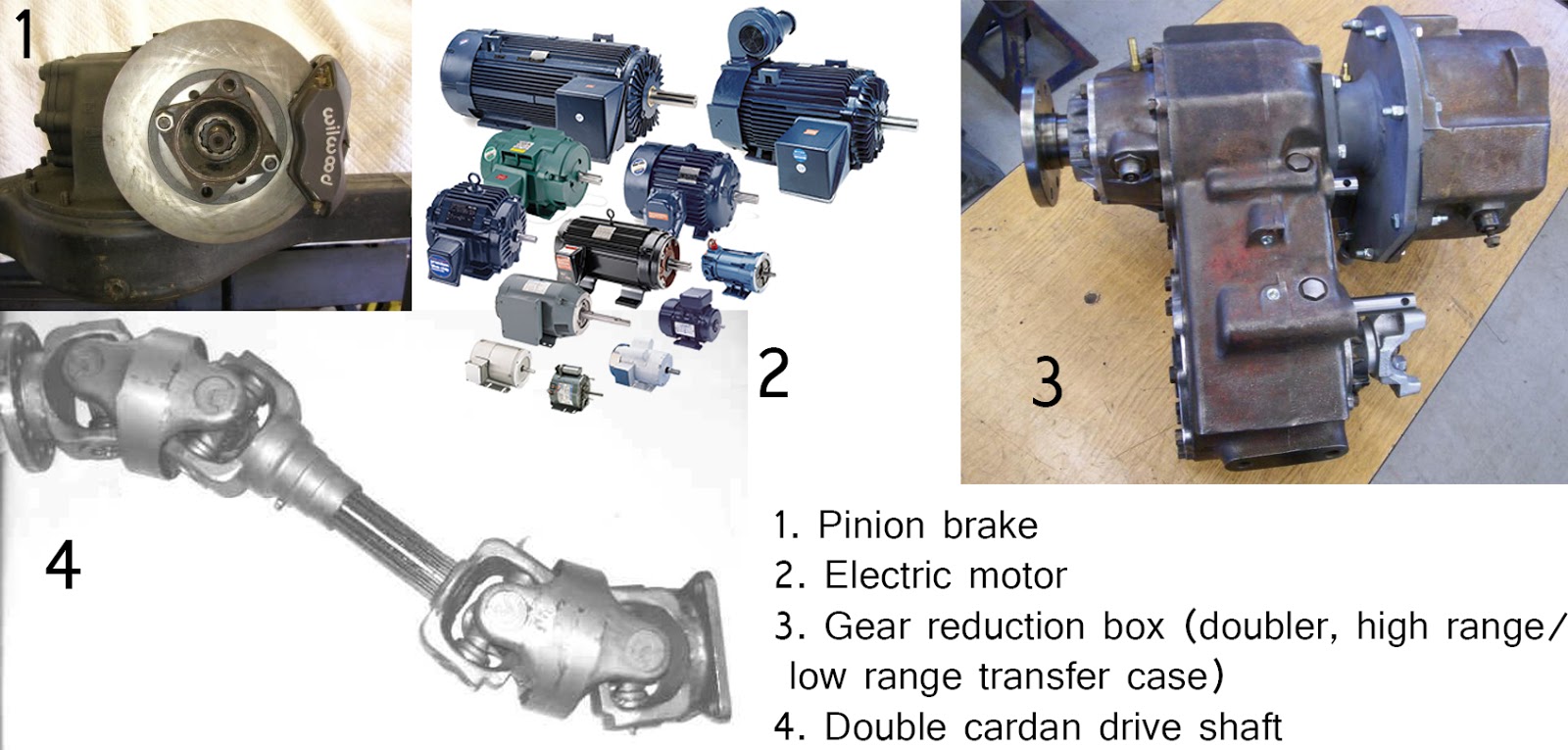

Applying the principles of a pinion brake/ inboard brake- the electric drive motors will rotate the shoulder/ hip joints, then the pinion brake will hold it in place, then the gear reduction/doubler box will allow more torque- since the long moment arm of the leg/arm will apply a huge amount of torque to the joint. Then the double cardan joint of a drive shaft should impart the rotational torque to the shoulder/hip.

Operator Interface:

Operator hangs in a hang glider harness, wearing a gyroscopic motion capture rig, used as a telemetry controller for the arms/legs. Still planning the interface for the front and rear cameras and HUD, as well as mechanical switches. I think I'll go with something similar to the AH-64 gunner/pilot slaved head mounted aiming device for the nose mounted cannon, mixed with something like Google Glass, mixed with the AN-PEQ 14 monocular night vision goggle. Something of a mix of those, should convey with the shape language that this is repurposed military tech used for a motorsports context. Since it's not possible for the operator to use pedals for the throttle, I'll have hand controls, but I'm still working out what controls he'll need immediate access to.

The fourwheeler reference image is the interior of an Ultra4 buggy, Shannon Campbell's ultra4 car to be specific. Left to right are a Lowrance gps unit, a racepak digital guage display, switches and breakers for all electronic components (race vehicles typically have manual switches for all components, so that non-critical components can be switched off, and breakers are favored over fuses to quickly see where a problem lies, as well as allowing for a quick reset of the breaker rather than digging through spare fuses and replacing it) then you see the Carr-Winters gated shifter, cutting brakes and the red dial is a blue sea battery selector/disconnect- not that most of you will care, but for those who do, not all of this stuff is easily learned, buried within the obscura of culture relevant message boards etc. I hope this dump of info isn't going to be a TL;DR thing- Just trying to help and show off a project I'm excited about.

The basic touchpoints of this project are that I want to convey without explanation are a few points:

- This is an exciting new motorsports culture

- These are non military- even though the direct reference is a DARPA robot for soldiers, I wanted to take inspiration and apply it to the motorsports world, just like offroad racing turned the Jeep, originally a military vehicle, into a racecar.

- To imply that the sponsors for the race teams aren't just parts manufacturers (blue torch fab, trent fabrication, genright, poison spyder custom, etc) I want to have sponsor logos include sports nutrition, yoga studios, UFC training camps, the like. I hope this imparts the sense on maybe a second level read, that this motorsport genre is physically demanding and not just a driving skill and engineering mastery type of sport.

Anyway.

For now, I'm trying to figure out how to implement a number of ideas but with a sense of 'I can build this in my garage' - trying to keep the b*llshit meter from going into the red

Any comments, critiques, questions, suggestions, whatever are totally welcome.

Stay tuned.

Loooong time lurker, first time project post, trying to get over that hump of being terrified and intimidated- I gotta post this if I'm going to get feedback and get better.

If gearhead talk bores you, scroll right past this text and look at the pictures

Here's a huge writeup fueled by coffee- if you like boring technical talk of mechanical stuff, indulge me! I HAVE A LOT OF COFFEE IN MY BELLY OH MY GOD

Ahem.

Seen here is the inspiration ingredient sheet:

"Rock Crawler" - representative sample, youtube video

[ame]

https://www.youtube.com/watch?v=acalNRlT2I0[/ame]

https://www.youtube.com/watch?v=acalNRlT2I0[/ame]The tubed-chassis 'buggy'- Rock crawlers typically remove as much sheet metal from the body as possible, for wheel travel, for less interference on obstacles (fenders and fender flares typically cut away, corners are 'comp cut', rocker panels are trimmed as high up on the sides as possible, etc). Crawlers are typically meant for methodical, slow paced driving over obstacles, i e rocks. Usually there are a lot of extra control measures- separate front/rear brakes for front and rear digs (spinning the front or rear wheels, burnout fashion will spin free the dirt or moss in the tread and then dry the tire for better traction- alternating front and rear with this action will maintain control- think of a rock climber chalking his hands), cutting brakes (think tractor brakes. two levers, one for each rear wheel, used to pivot on one of the rear wheels for steering rather than using the front wheels), hand throttle (sometimes a modified bmx brake lever mounted to the shifter- basically allows one hand on the steering wheel, one hand on the shifter controlling shifting and throttle input, and one foot on the clutch and one foot on the brakes) . Very technical rigs, great engineering resource. For mechanical reference, I suggest you check out the Pirate4x4 forums, such as the Jeep forum, as an example: http://www.pirate4x4.com/forum/jeep-hardcore-tech/804177-heavily-mogified.html

http://www.pirate4x4.com/forum/jeep-hardcore-tech/882928-project-dookeys-revenge.html

"Rock Bouncer" - representative sample, youtube video

[ame]

https://www.youtube.com/watch?v=4A98SJg-iuc[/ame]

https://www.youtube.com/watch?v=4A98SJg-iuc[/ame]Rock Bouncers are sort of a sub culture of rock crawling, typically regarded as the more 'daredevil' crowd. You'll see more instances of LPG powered engines- a gas engine that's carbeurated will have trouble in off-camber or deeply tilted angles, remedied by running electronic fuel injection, but that still has its limits- so these guys will run propane-powered rigs a lot. Idea being, this will run the same when upside down. Rock Bouncers are typically automatic transmission (go pedal, stop pedal) for simplicity, typically don't have a winch ( recovery is just a matter of gunning the gas and flipping back over

"Big Dog" - schematics pdf, technical documentation, representative video

video- [ame]

https://www.youtube.com/watch?v=W1czBcnX1Ww[/ame]

https://www.youtube.com/watch?v=W1czBcnX1Ww[/ame]pdf: http://www.bostondynamics.com/img/BigDog_IFAC_Apr-8-2008.pdf

http://www.bostondynamics.com/img/BigDog_Overview.pdf

http://www.bostondynamics.com/robot_bigdog.html

15 horsepower go-kart engine

Engine:

since this is a scaled up version of the Big Dog/ Wildcat, I'll be using a 'small block chevy 350 cubic inch' naturally aspirated v8 engine. On the low end, a crate engine will produce around ~200 horsepower with a pretty flat torque curve, but since in this usage it's mainly for a direct RPM - to - PTO for the hydraulic pumps and the alternator to power the electronics, it's all about a fast revving torque-y engine. The video below should give an idea of how I imagine the 'crawler' will sound, big contrast from the whiny mosquito engine from the video above:

[ame]

https://www.youtube.com/watch?v=hyPQzPKIqsk&list=FLRo0FvL9EPL6UWq2mLX-Rhg&index=48[/ame]

https://www.youtube.com/watch?v=hyPQzPKIqsk&list=FLRo0FvL9EPL6UWq2mLX-Rhg&index=48[/ame]Ambulatory modules:

Applying the principles of a pinion brake/ inboard brake- the electric drive motors will rotate the shoulder/ hip joints, then the pinion brake will hold it in place, then the gear reduction/doubler box will allow more torque- since the long moment arm of the leg/arm will apply a huge amount of torque to the joint. Then the double cardan joint of a drive shaft should impart the rotational torque to the shoulder/hip.

Operator Interface:

Operator hangs in a hang glider harness, wearing a gyroscopic motion capture rig, used as a telemetry controller for the arms/legs. Still planning the interface for the front and rear cameras and HUD, as well as mechanical switches. I think I'll go with something similar to the AH-64 gunner/pilot slaved head mounted aiming device for the nose mounted cannon, mixed with something like Google Glass, mixed with the AN-PEQ 14 monocular night vision goggle. Something of a mix of those, should convey with the shape language that this is repurposed military tech used for a motorsports context. Since it's not possible for the operator to use pedals for the throttle, I'll have hand controls, but I'm still working out what controls he'll need immediate access to.

The fourwheeler reference image is the interior of an Ultra4 buggy, Shannon Campbell's ultra4 car to be specific. Left to right are a Lowrance gps unit, a racepak digital guage display, switches and breakers for all electronic components (race vehicles typically have manual switches for all components, so that non-critical components can be switched off, and breakers are favored over fuses to quickly see where a problem lies, as well as allowing for a quick reset of the breaker rather than digging through spare fuses and replacing it) then you see the Carr-Winters gated shifter, cutting brakes and the red dial is a blue sea battery selector/disconnect- not that most of you will care, but for those who do, not all of this stuff is easily learned, buried within the obscura of culture relevant message boards etc. I hope this dump of info isn't going to be a TL;DR thing- Just trying to help and show off a project I'm excited about.

The basic touchpoints of this project are that I want to convey without explanation are a few points:

- This is an exciting new motorsports culture

- These are non military- even though the direct reference is a DARPA robot for soldiers, I wanted to take inspiration and apply it to the motorsports world, just like offroad racing turned the Jeep, originally a military vehicle, into a racecar.

- To imply that the sponsors for the race teams aren't just parts manufacturers (blue torch fab, trent fabrication, genright, poison spyder custom, etc) I want to have sponsor logos include sports nutrition, yoga studios, UFC training camps, the like. I hope this imparts the sense on maybe a second level read, that this motorsport genre is physically demanding and not just a driving skill and engineering mastery type of sport.

Anyway.

For now, I'm trying to figure out how to implement a number of ideas but with a sense of 'I can build this in my garage' - trying to keep the b*llshit meter from going into the red

Any comments, critiques, questions, suggestions, whatever are totally welcome.

Stay tuned.

Replies

Good luck!

As usual, awesome reaserching.

Would love to see some higher-res screengrabs of the model itself, as the current ones are abit too small.

Good luck with the modelling, and will tune in to see more.

RogelioD, Karmageddon, RJ, Yoseppe, Damian-

Thank you for taking a look!

I'm working out the mechanics still, I'm pretty pleased with the mounting of the shoulder but the hinge tab still looks a little weak, but then again I've seen stuff of similar size holding similar weight- and since this is a low-speed (relatively) vehicle, I may justify it.

More work today, but just an update at the moment.

trying out Gyazo, looking to see how long an upload/grab stays up. if it starts taking things down after, say, a day or so it would be good to know.

also- i was too focused on/ obsessed with making the mechanisms all be direct pulls (tech wise) from motorsports, then just repurposed. I figured, since race teams put hundreds of thousands of dollars into their race rigs and source parts from all kinds of industries, it wouldn't be too much of a stretch to see something from industrial robotics being used here.

Now the only stretch is that it's powered by a 12v or 24v system, but 99% of anyone seeing this stuff would care...

example image of intended result

Yep. TIG welds with heat anodized rainbow look is planned.

Specifically going with TIG over MIG, oxyacetyline, arc, etc, BECAUSE RACECAR (reference to a meme in motorsports)

Thanks for looking!

That's a really cool shot! Gonna love to see how you tackle that!